Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

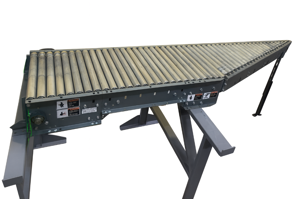

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Still Electric Forklift RX20-20PL

Create an account to install this asset package.

Maintenance Plans for Still Electric Forklift Model RX20-20PL

Integrate maintenance plans directly into your work orders in MaintainX.

1000 Hourly / 1 Yearly Hydraulic System Check

1. Check the condition of the hydraulic system, check that it is working correctly and check for leaks - Hose lines must be changed if

• The outer layer has been breached or becomes brittle with tears

• They are leaking

• There are unnatural deformations (e.g. bubble formation or buckling)

• A fitting is detached from the hose

• A fitting is badly damaged or corroded

- Pipes must be changed if

• There is abrasion with the loss of material

• There are unnatural deformations and detectable bending stress

1 Weekly Lead Acid Battery Charging

Warning: Only trained personnel should perform this procedure

Lead-acid batteries charged at least once per week

All battery cells evenly charged

Deep discharge of the battery prevented

Sign off on the battery charging procedure

1000 Hourly / 1 Yearly Electrical System Check

Check all power cable connections

Check that the switches, transmitters and sensors are working correctly

Check the lighting and indicator lights

1000 Hourly / 1 Yearly Brake System Maintenance

Check the condition of all mechanical brake parts and check that they are working correctly

Check the actuation distance of the foot brake and adjust if necessary

Check the manual force required to apply the handbrake and adjust if necessary

Check the play between the fork clevis and the axle lever and adjust if necessary

Perform a brake test

1000 Hourly / 1 Yearly Steering System Check

Check the steering system for leaks and check that it is working correctly

Check that the steering wheel is securely attached and check the rotary handle for damage

Check that the steering axle is securely mounted, check for leaks and apply grease

Check the steering stop

Sign off on the steering system check

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX