Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

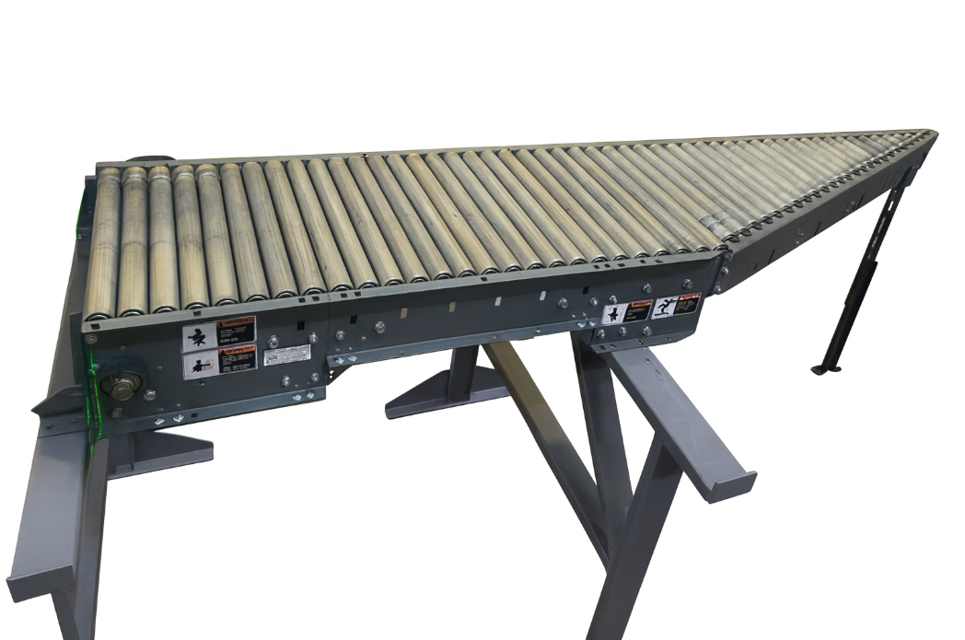

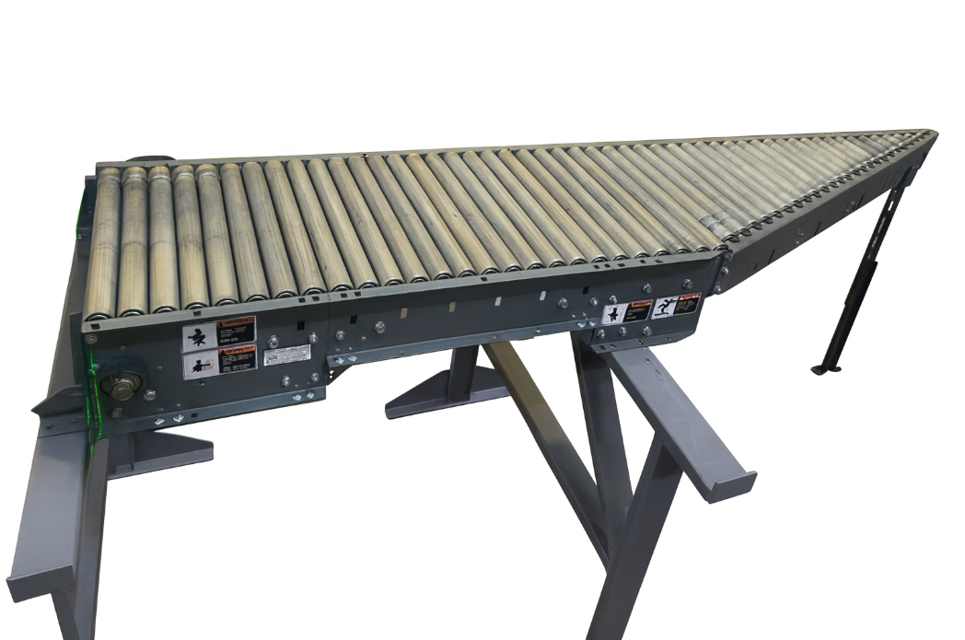

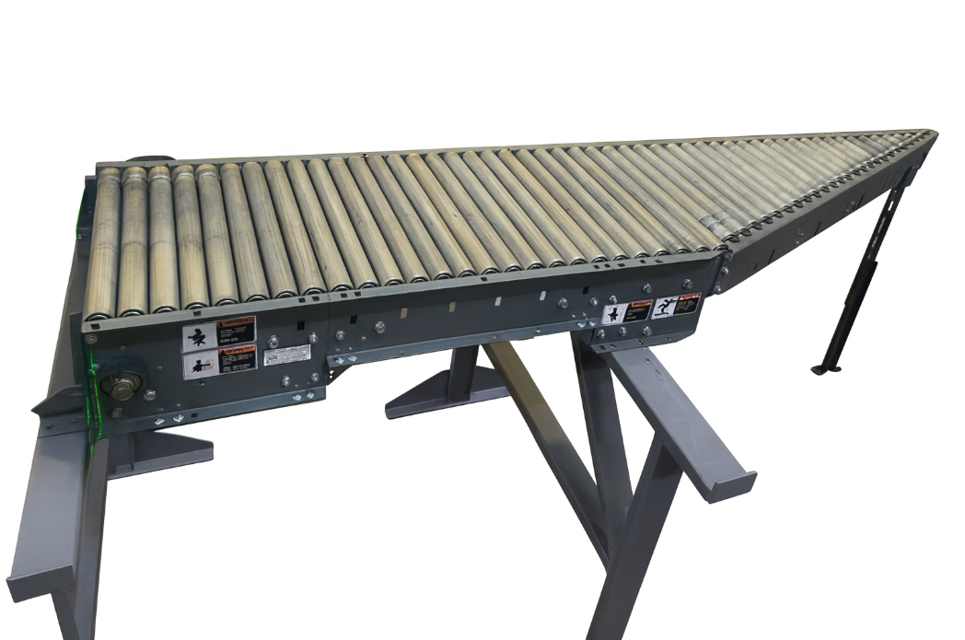

Intelligrated Conveyor Powered Roller

Create an account to install this asset package.

Maintenance Plans for Intelligrated Conveyor Model Powered Roller

Integrate maintenance plans directly into your work orders in MaintainX.

1040 Hourly / 6 Monthly Powered Roller Conveyor Maintenance

Recommended service checks and equipment maintenance are outlined below for typical, intermittent-duty conveyor applications. Additional maintenance and servicing schedule adjustments may be required for continuous-duty operation or extreme environmental conditions.

All newly installed equipment should be frequently inspected and serviced as needed during the first 40 hours of operation; thereafter, an appropriate maintenance program should be established and followed (see Table E-1).

Maintaining separate service log sheets on each type of conveyor is recommended for plants operating more than one shift. Each log sheet should show dates, detailed inspection service information, and name or initials of person(s) performing the equipment inspection or service for future reference.

CAUTION: Before performing maintenance on a conveyor, make certain that the conveyor’s power disconnect is locked in the OPEN position and tagged to prevent accidental or unexpected application of power.

Do not perform maintenance while the conveyor is running unless specifically instructed to do so in this manual.

Note: Other than checking of chain tension, it is NOT necessary to have the conveyor turned ON in order to perform any of the work described in this section.

Maintenance must be performed only by qualified personnel who are trained in normal and emergency operations of the conveyor and who are knowledgeable of all safety devices, their locations, and functions.

Before restarting a conveyor:

• Remove all foreign objects from the conveyor.

Initial 40 Hours Powered Roller Conveyor Maintenance

Recommended service checks and equipment maintenance are outlined below for typical, intermittent-duty conveyor applications. Additional maintenance and servicing schedule adjustments may be required for continuous-duty operation or extreme environmental conditions.

All newly installed equipment should be frequently inspected and serviced as needed during the first 40 hours of operation; thereafter, an appropriate maintenance program should be established and followed (see Table E-1).

Maintaining separate service log sheets on each type of conveyor is recommended for plants operating more than one shift. Each log sheet should show dates, detailed inspection service information, and name or initials of person(s) performing the equipment inspection or service for future reference.

CAUTION: Before performing maintenance on a conveyor, make certain that the conveyor’s power disconnect is locked in the OPEN position and tagged to prevent accidental or unexpected application of power.

Do not perform maintenance while the conveyor is running unless specifically instructed to do so in this manual.

Note: Other than checking of chain tension, it is NOT necessary to have the conveyor turned ON in order to perform any of the work described in this section.

Maintenance must be performed only by qualified personnel who are trained in normal and emergency operations of the conveyor and who are knowledgeable of all safety devices, their locations, and functions.

Before restarting a conveyor:

• Remove all foreign objects from the conveyor.

1 Weekly Powered Roller Conveyor Maintenance

CAUTION: Before performing maintenance on a conveyor, make certain that the conveyor’s power disconnect is locked in the OPEN position and tagged to prevent accidental or unexpected application of power.

Do not perform maintenance while the conveyor is running unless specifically instructed to do so in this manual.

Maintenance must be performed only by qualified personnel who are trained in normal and emergency operations of the conveyor and who are knowledgeable of all safety devices, their locations, and functions.

Before restarting a conveyor: Remove all foreign objects from the conveyor. Be sure that all guards and safety devices are properly installed and working. Make sure that all persons are clear of the conveyor and are aware that the conveyor is about to be restarted.

Check Physical Condition Air Pressure Regulator & Filter

Check Operation Air Pressure Regulator & Filter

Check Proper Position Carrier Rollers

Check Physical Condition Carrier Rollers

Check Operation Carrier Rollers

Initial 100 Hours Power Unit Reducer Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Note: All reducers tend to run hot when first put into operation until the maximum break-in efficiency is reached (approx. 120 hours).

Enter the current operation hours of the unit

Has the unit been operated for 100 hours?

If the unit has not been operated for 100 hours, stop the procedure

Enter the type of solvent used for flushing

Was the gearcase successfully flushed with the solvent?

Enter the type of lubricant used for refilling

Was the gearcase successfully refilled with fresh lubricant?

1 Monthly Powered Roller Conveyor Maintenance

CAUTION: Before performing maintenance on a conveyor, make certain that the conveyor’s power disconnect is locked in the OPEN position and tagged to prevent accidental or unexpected application of power.

Do not perform maintenance while the conveyor is running unless specifically instructed to do so in this manual.

Maintenance must be performed only by qualified personnel who are trained in normal and emergency operations of the conveyor and who are knowledgeable of all safety devices, their locations, and functions.

Before restarting a conveyor: Remove all foreign objects from the conveyor. Be sure that all guards and safety devices are properly installed and working. Make sure that all persons are clear of the conveyor and are aware that the conveyor is about to be restarted.

Check Fasteners Bearings - External

Check Set Screws Bearings - External

Check Physical Condition Bearings - External

Check Lubrication Drive Chain - Internal

Check Tension Drive Chain - Internal

Parts for Intelligrated Conveyor Powered Roller

Access the parts list for your equipment in MaintainX.

Axle Bolt - Hx Hd, 3/8" X 2-3/4"

22-1053

Axle Bushing (Steel) 5/8" Dia.

69-2603

Cable Tie / Ty-Ra (Not Shown)

30-0087

Cap Plug (For Lower Zone Enclosure - Not Shown)

30-0089

Chain - Rc-40

20-0551

Axle Bolt - Hx Hd, 3/8" X 2-3/4"

22-1053

Axle Bushing (Steel) 5/8" Dia.

69-2603

Cable Tie / Ty-Ra (Not Shown)

30-0087

Cap Plug (For Lower Zone Enclosure - Not Shown)

30-0089

Chain - Rc-40

20-0551

Axle Bolt - Hx Hd, 3/8" X 2-3/4"

22-1053

Axle Bushing (Steel) 5/8" Dia.

69-2603

Cable Tie / Ty-Ra (Not Shown)

30-0087

Cap Plug (For Lower Zone Enclosure - Not Shown)

30-0089

Chain - Rc-40

20-0551

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX