Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Chicago Pneumatic Air Compressor CPC 60

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

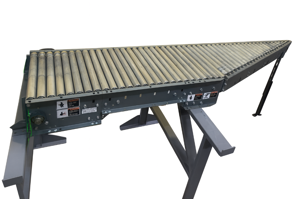

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Chicago Pneumatic Air Compressor CPC 60

Create an account to install this asset package.

Maintenance Plans for Chicago Pneumatic Air Compressor Model CPC 60

Integrate maintenance plans directly into your work orders in MaintainX.

500 Hourly Air Compressor Maintenance

Warning: Before carrying out any maintenance it is mandatory to stop the compressor and disconnect it from the main power.

Maintenance on the electrical components can only be performed by qualified technicians or authorized factory personnel.

Caution: When the compressed air cools, part of the moisture sucked in by the compressor condenses. It is essential to check regularly that the condensate drains are operating properly.

Clean the air suction filter

Cleaning the suction filter or changing the filter

Press the “STOP” button

Switch off the compressor.

Turn off main power and lockout disconnect

Remove the side maintenance panel using the supplied key.

2000 Hourly Air Compressor Maintenance

OPERATIONS THAT REQUIRE SKILLED PERSONNEL:

Change the oil filter

OPERATIONS THAT MAY BE CARRIED OUT BY THE USER:

Change the suction filter.

BEFORE CARRYING OUT ANY MAINTENANCE IT IS MANDATORY TO STOP THE COMPRESSOR AND DISCONNECT IT FROM THE MAIN POWER.

MAINTENANCE ON THE ELECTRICAL COMPONENTS CAN ONLY BE PERFORMED BY QUALIFIED TECHNICIANS OR AUTHORIZED FACTORY PERSONNEL.

CAUTION

When the compressed air cools, part of the moisture sucked in by the compressor condenses. In order to protect the dryer against the risk of an ice plug forming, it is essential to check regularly that the condensate drains are operating properly :

On the compressed air storage reservoir and on the filters :

8000 Hourly Air Compressor Maintenance

OPERATIONS THAT REQUIRE SKILLED PERSONNEL

BEFORE CARRYING OUT ANY MAINTENANCE IT IS MANDATORY TO STOP THE COMPRESSOR AND DISCONNECT IT FROM THE MAIN POWER.

MAINTENANCE ON THE ELECTRICAL COMPONENTS CAN ONLY BE PERFORMED BY QUALIFIED TECHNICIANS OR AUTHORIZED FACTORY PERSONNEL.

CAUTION

Check regularly that the condensate drains are operating properly

CHANGING THE OIL

BEFORE CARRYING OUT ANY MAINTENANCE IT IS MANDATORY TO STOP THE COMPRESSOR AND DISCONNECT IT FROM THE MAIN POWER AND FROM THE COMPRESSED AIR DISTRIBUTION NETWORK.

Drain the old oil out of the compressor

Fill the oil tank to the MAX level

4000 Hourly Air Compressor Maintenance

Warning: Operations that require skilled personnel

Clean the finned surface of the air-oil cooler

Change the oil separating filter

Before carrying out any maintenance it is mandatory to stop the compressor and disconnect it from the main power.

Maintenance on the electrical components can only be performed by qualified technicians or authorized factory personnel.

Caution: When the compressed air cools, part of the moisture sucked in by the compressor condenses.

Check regularly that the condensate drains are operating properly

Changing the oil separation filter

Before carrying out any maintenance the compressor must be stopped, disconnect the compressor from the main power and from the compressed air distribution network, check that the compressor is not under pressure.

50 Hourly Air Compressor Maintenance

OPERATIONS THAT MAY BE CARRIED OUT BY THE USER:

Drain condensate from the SUMP TANK

Check the oil level

Clean the filtering panel.

BEFORE CARRYING OUT ANY MAINTENANCE IT IS MANDATORY TO STOP THE COMPRESSOR AND DISCONNECT IT FROM THE MAIN POWER.

MAINTENANCE ON THE ELECTRICAL COMPONENTS CAN ONLY BE PERFORMED BY QUALIFIED TECHNICIANS OR AUTHORIZED FACTORY PERSONNEL.

CAUTION

When the compressed air cools, part of the moisture sucked in by the compressor condenses. In order to protect the dryer against the risk of an ice plug forming, it is essential to check regularly that the condensate drains are operating properly :

On the compressed air storage reservoir and on the filters :

Parts for Chicago Pneumatic Air Compressor CPC 60

Access the parts list for your equipment in MaintainX.

Filter Panel

2202260554

Filter Panel (For IVR)

D51210

Suction Filter

641128

Separator Element

640584

Oil Filter

2202260271

Filter Panel

2202260554

Filter Panel (For IVR)

D51210

Suction Filter

641128

Separator Element

640584

Oil Filter

2202260271

Filter Panel

2202260554

Filter Panel (For IVR)

D51210

Suction Filter

641128

Separator Element

640584

Oil Filter

2202260271

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX