Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

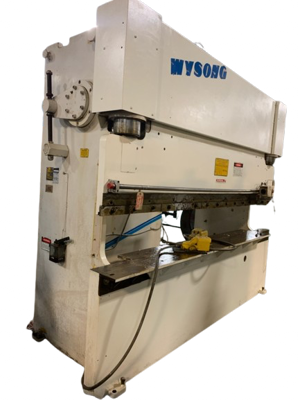

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

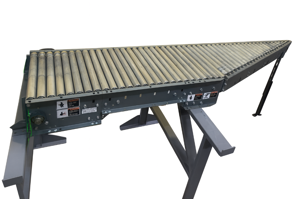

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Tennant Floor Scrubber T300

Create an account to install this asset package.

Maintenance Plans for Tennant Floor Scrubber Model T300

Integrate maintenance plans directly into your work orders in MaintainX.

Floor Scrubber Maintenance

BATTERIES

FOR SAFETY: Before servicing machine, stop on level surface, turn off machine and remove key.

Your machine is equipped with either flooded (wet) lead‐acid, maintenance‐free (Sealed AGM) batteries or lithium-ion battery supplied by Tennant.

LITHIUM−ION BATTERY

The lithium−ion battery pack is a maintenance−free battery protected by a battery management system (BMS). To achieve the maximum battery life, carefully follow the instructions below:

Lithium−Ion batteries must be charged prior to initial use.

Carefully follow the Important Safety Instructions section in the manual when using the Lithium−ion Battery Model.

Only use the lithium−ion battery charger supplied with machine.

Charge battery pack in well−ventilated areas. For best charging performance, charge the battery pack in temperatures below 80F/27C and above 32F/0C. Battery pack may shut down and not take a charge in elevated or freezing temperatures.

Water Conditioning Cartridge Replacement

FOR SAFETY: Before leaving or servicing machine, stop on level surface, turn off machine, remove key and set parking brake if equipped.

The water conditioning cartridge is required to be replaced when it reaches its maximum water usage or expiration time of when the cartridge was activated, which ever comes first. The control panel will signal a code when it’s time to replace cartridge.

Depending on machine usage, on average, a new cartridge can last anywhere from 12 months for heavy machine usage to 24 months for light machine usage.

ATTENTION: During first time use and after replacing the water conditioning cartridge, the ec-H2O system will automatically override the solution flow setting to the maximum flow rate for up to 60 minutes to properly prime the cartridge. During this time, the machine can be operated as normal.

Park the machine on a level surface, remove the key and set parking brake, if equipped.

Lift the recovery tank to access the ec-H2O water conditioning cartridge. Drain recovery tank before lifting tank.

Disconnect the two hose connectors from the top of the cartridge by pressing the gray collars inward and pulling the connectors outward. Lift cartridge to remove.

Fill in the installation date on the new cartridge label.

Install the new cartridge and reconnect the two hoses. Make sure the hose connectors are fully inserted into the cartridge.

1250 Hourly Floor Scrubber Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Propel motor - Carbon brushes replaced?

Brush motor - Carbon brushes replaced?

Brush belt - Belt replaced?

Sign off on the floor scrubber maintenance

50 Hourly Floor Scrubber Maintenance

To be done by operator

Cylindrical brushes - Rotate brushes. Check for wear

Cylindrical scrub head - Clean underside of scrub head

Recovery tank lid seal - Check for wear

Solution tank filter - Clean

AFTER EVERY 50 HOURS OF USE

Remove the solution tank filter and clean screen. Turn the filter bowl counter-clockwise to remove. Make sure to drain solution tank before removing filter

Cylindrical brushes − Rotate brushes from front to rear. Replace brushes when they no longer clean effectively

Cylindrical scrub head − Remove debris buildup from underside of scrub head

1 Weekly Floor Scrubber Maintenance

To be done by operator:

Battery cells - Check electrolyte level

Squeegee assembly drip trap reservoir - Check, clean.

AFTER WEEKLY USE

Check the electrolyte level in all batteries

Remove the drip trap cover from the squeegee assembly and clean reservoir.

FLOODED (WET) AND MAINTENANCE-FREE SEALED LEAD-ACID BATTERIES

Do not charge the batteries more than once a day and only after running the machine for a minimum of 15 minutes.

Do not leave the batteries partially discharged for long period of time.

Parts for Tennant Floor Scrubber T300

Access the parts list for your equipment in MaintainX.

Kit

9021730

Kit

9021730

Kit

9021730

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX