Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

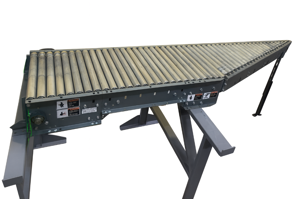

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Still Electric Forklift RX20-18PL

Create an account to install this asset package.

Maintenance Plans for Still Electric Forklift Model RX20-18PL

Integrate maintenance plans directly into your work orders in MaintainX.

1000 Hourly / 1 Yearly Hydraulic Oil Level Check

Park the truck securely

CAUTION! Risk of component damage! If you remove the battery male connector when the key switch is switched on (under load), an arc will be produced. This can lead to erosion at the contacts, which considerably shortens their service life

Switch off the key switch before the battery male connector is disconnected

Only disconnect the battery male connector with the key switch switched on in an emergency

Battery male connector disconnected

Maintenance lid or bottom plate removed

CAUTION! Hydraulic oils are hazardous to your health and are under pressure during operation. Note the safety regulations in the 'Hydraulic fluid' chapter

CAUTION! Risk of damage to components! Remove connector for drive unit

Breather filter unscrewed

Seat Belt Maintenance

- Cleaning the seat belt

1. Clean the seat belt as necessary, but without using chemical cleaning materials (a brush will suffice)

- Replacement after an accident

1. As a rule, the seat belt must be changed after an accident;

1000 Hourly / 1 Yearly Cooling System Maintenance

Check that the fans and the air ducts are working correctly and check for damage

Clean the fans and the air ducts

Clean the cooling fins on the converter and the traction motors

1000 Hourly / 1 Yearly Lift Mast Check

Check the mast bearings for damage

Lubricate the mast bearings and check the tightening torque

Check the mast profiles for damage and wear

Lubricate the mast profiles

Check the guide in the lower (load reversal) mast profile for damage and for wear

Check the load chains for damage and wear

Adjust and lubricate the load chains

Check the lift cylinders and connections for damage and for leaks

Check the guide pulleys for damage and for wear

Drive Seat Check

WARNING! Risk of injury! After an accident, check the driver's seat with attached restraining belt and fastening

Check the controls for correct operation

Check the condition of the seat (e.g. wear on the upholstery) and secure fastening to the hood

WARNING Risk of injury! Have the seat repaired by the service centre if you identify any damage during the checks

Sign off on the drive seat check

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX