Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

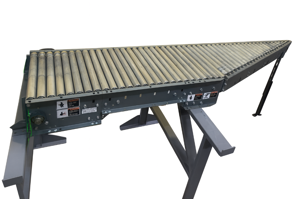

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Still Electric Forklift RX20-18L

Create an account to install this asset package.

Maintenance Plans for Still Electric Forklift Model RX20-18L

Integrate maintenance plans directly into your work orders in MaintainX.

Seat Belt Maintenance

- Cleaning the seat belt

1. Clean the seat belt as necessary, but without using chemical cleaning materials (a brush will suffice)

- Replacement after an accident

1. As a rule, the seat belt must be changed after an accident;

1000 Hourly Interlock Mechanism Lubrication

NOTE! The interval for greasing is influenced significantly by the application conditions and the environmental conditions affecting the truck. Visual inspections and function checking of the interlock must be carried out as required and after every 1000 hours. Grease all moving parts of the interlock as necessary

Open the battery door (1)

Check that the door lock (2) and the battery lock (4) move easily and that they are not deformed or damaged

Check that the indexing bolt (3) on the door lock is seated correctly and that it is not deformed or damaged

Grease the mechanisms of the interlocks

Close the battery door again

Sign off on the interlock mechanism lubrication

1000 Hourly / 1 Yearly Chassis, Bodywork and Fittings Check

Check the chassis for cracks

Check the overhead guard/cab and panes of glass for damage

Check that the cab door sensor is working correctly and check for damage

Check the controls, switches and joints for damage, and apply grease and oil

Check that the driver's seat is working correctly and check for damage

Check that the driver restraint system is working correctly and check for damage, and clean

Check the signal horn

Check the dual-pedal variant for damage and that it is working correctly, and lubricate

Sign off on the chassis, bodywork and fittings check

1000 Hourly / 1 Yearly Forklift Maintenance

1. Read out the error numbers and clear the list

2. Reset the maintenance interval

3. Check that the labelling is complete

4. Perform a test drive

- Lif Cylinder Check (p. 357)

"WARNING! Risk of injury! Observe safety regulations for working on the lift mast, see the ""Working at the front of the truck"" chapter

1. Check the hydraulic connections and lift cylinder for leaks (visual inspection)

2. Have leaking screw joints or leaking hydraulic cylinders repaired by the authorised service centre;" - Fork Arms Check (p. 358)

1. Check the fork arms (1) for any visible deformation. Wear must not amount to more than 10% of the original thickness

1000 Hourly / 1 Yearly Power Unit Maintenance

Check the mounting of the drive axle, check for leaks and clean the cooling fins

Check that the conductor rails between the power modules and the motor connections are mounted correctly

Check the oil level in the drive wheel unit and the multi-disc brake

Change the gearbox oil (once after the first 1000 hours)

Sign off on the power unit maintenance

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX