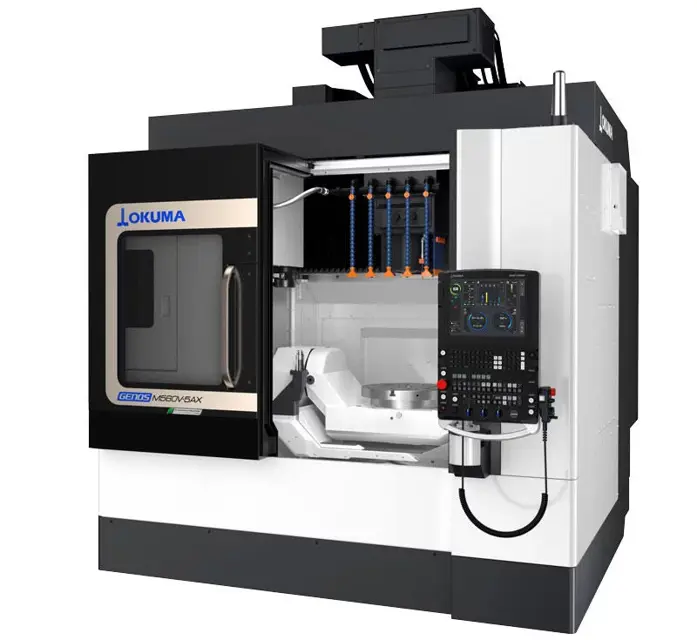

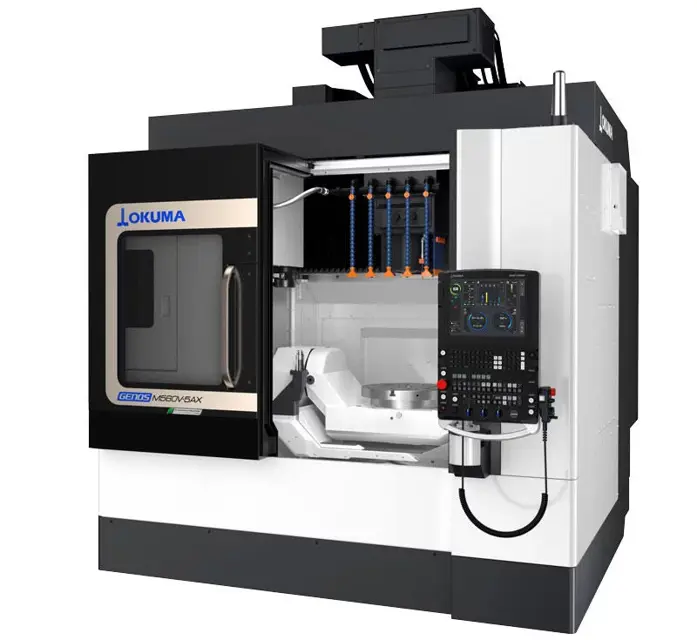

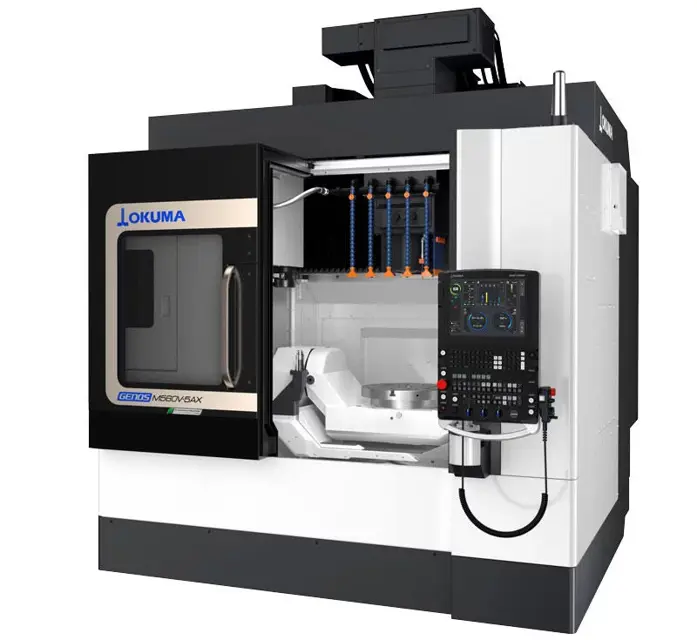

The Okuma 5-Axis Vertical Machining Center M560-V is a high-precision CNC machine designed for complex machining tasks. Known for its robust construction and advanced technology, this model enhances productivity and accuracy in various industrial applications. Ideal for manufacturers seeking reliable performance and versatility.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Okuma 5-Axis Vertical Machining Center M560-V

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Okuma 5-Axis Vertical Machining Center M560-V

Create an account to install this asset package.

Maintenance Plans for Okuma 5-Axis Vertical Machining Center Model M560-V

Integrate maintenance plans directly into your work orders in MaintainX.

5 Monthly Oil-Air Lubrication Unit Oil Replacement

Specified Oil: ExxonMobil DTE Oil Light

Tank Capacity: 2 liter (0.5 US gal)

Oil Change Interval Depends on the operating condition.

Normally, the oil lasts 5 months when supplied to the effective tank capacity.

Filter Cleaning Interval: Clean the pump filter in the tank every 6 months and change every year.

CAUTION: Always use the specified oil. Supply clean and new oil up to the H level. When supplying oil, be careful not to include dust in the oil.

Use of unspecified lubricating oil could bring serious damage to the spindle.

Check the oil amount every morning when starting operation. If the oil level drops as low as L level, an alarm C occurs and the machine stops. Therefore, supply oil a little bit earlier than lighting of the alarm lamp.

For the precautions on oil-air lubrication, refer to Section 1, 7-1. “Spindle Lubrication (Oil-air)”. For details regarding the oil-air lubrication unit, refer to Instruction Manual for Centralized Lubrication Unit MR-LUB (Daido Metal) compiled in the Purchased Unit Instruction Manual.

2000 Hourly Spindlehead Cooling Unit Oil Replacement

Warning: Make sure to cut off the power before supplying or replenishing the cooling oil.

Enter the current machine operation hours

Is the correct oil (FC2) being used?

Enter the amount of oil used in liters

Did you refill the tank after operating the machine once?

Reminder: Do not change the set temperature on the control panel.

Is the filter clean?

Sign off on the oil replacement procedure

Parts for Okuma 5-Axis Vertical Machining Center M560-V

Access the parts list for your equipment in MaintainX.

Spindlehead Cooling Unit #40: 8000 min-1

P-BO-V750PTSBM6-172

Spindlehead Cooling Unit #40: 12000 min-1

P-BO-V900PTSBM6-6

Spindlehead Cooling Unit #40: 8000 min-1

P-BO-V750PTSBM6-172

Spindlehead Cooling Unit #40: 12000 min-1

P-BO-V900PTSBM6-6

Spindlehead Cooling Unit #40: 8000 min-1

P-BO-V750PTSBM6-172

Spindlehead Cooling Unit #40: 12000 min-1

P-BO-V900PTSBM6-6

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX