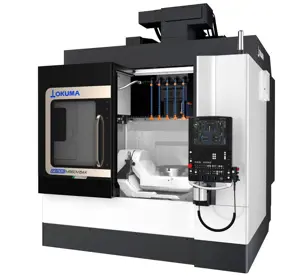

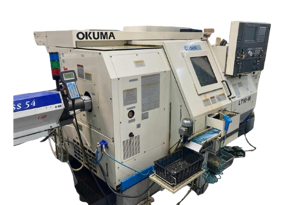

The Okuma Lathe LB15B is a high-performance CNC lathe designed for precision machining in industrial applications. Known for its reliability and advanced features, this model offers exceptional accuracy and efficiency, making it ideal for various manufacturing processes. Optimize your operations with the LB15B's robust capabilities.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Okuma Lathe LB15B

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Okuma Lathe LB15B

Create an account to install this asset package.

Maintenance Plans for Okuma Lathe Model LB15B

Integrate maintenance plans directly into your work orders in MaintainX.

Tapered Gib Adjustment

Warning: This procedure requires trained personnel with PPE!

Machine showing irregular feed movement?

If machine is not showing irregular feed movement, stop the procedure

Covers removed from the left- and right-hand sides of the Z-axis slide?

Gib A at the thinner side loosened?

Thicker side of gib A fully tightened and then returned by one-half turn?

Thinner side of gib A tightened?

Thicker side of gib A tightened?

Enter the clearance measurement

Turret Indexing Speed Adjustment

Warning: This procedure requires trained personnel with PPE!

Enter the oil temperature in the tank

If oil temperature is below 40°C, warm up the hydraulics until it reaches 40°C

Is the clamp/unclamp speed adjusting valve (1) set at 'L' 14 mm (0.55')?

Is the clutch meshing noise not heard when rotating the turret and tightening the valve (3)?

Enter the turret indexing speed

If oil temperature is 30°C, set the turret indexing speed at 4.5 seconds per turn

Is the turret indexing time adjustable at 0.8 seconds per station at an oil temperature of 40°C?

Sign off on the turret indexing speed adjustment

6 Monthly Lathe Maintenance

Change lubricating oil in the headstock lubrication system

Change hydraulic oil in the hydraulic power unit

Check and adjust belt tension

Sign off on the lathe maintenance

Bed Level Check

Warning: This check requires trained personnel!

Is the bedway straight?

Can parts be turned to specified tolerances?

If not, secure the machine level

Did the adjustment improve the machining accuracy?

Sign off on the bed level check

Turret Indexing Time Check

Warning: This procedure requires trained personnel!

Is the OSP software available and functional?

If OSP software is not functional, report the issue to the maintenance team and stop the procedure

Was the turret manually indexed?

Was the display page switched to the CHECK DATA page?

Was the AXIS DATA page accessed?

Enter the turret indexing time displayed at X column

Enter the turret indexing time displayed at Z column

Are the values at X and Z columns identical?

Parts for Okuma Lathe LB15B

Access the parts list for your equipment in MaintainX.

Strainer Hydraulic Power Unit

H0949-0000-29

Pressure Gauge Hydraulic Power Unit

T019-490-000-83

Line Filter Hydraulic Power Unit

H0032-0001-08

Dester Plunger Tailstock

H0012-0004-95

Timing Belt X-Axis Drive Servomotor

M119-9066-91

Strainer Hydraulic Power Unit

H0949-0000-29

Pressure Gauge Hydraulic Power Unit

T019-490-000-83

Line Filter Hydraulic Power Unit

H0032-0001-08

Dester Plunger Tailstock

H0012-0004-95

Timing Belt X-Axis Drive Servomotor

M119-9066-91

Strainer Hydraulic Power Unit

H0949-0000-29

Pressure Gauge Hydraulic Power Unit

T019-490-000-83

Line Filter Hydraulic Power Unit

H0032-0001-08

Dester Plunger Tailstock

H0012-0004-95

Timing Belt X-Axis Drive Servomotor

M119-9066-91

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX