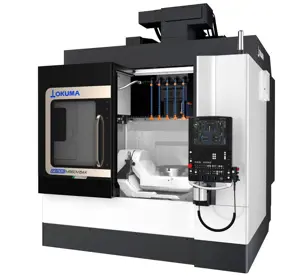

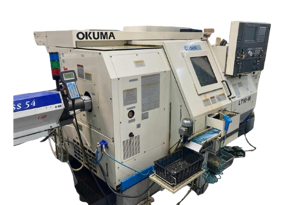

The Okuma Lathe LU-15MW is a high-precision CNC lathe designed for efficient machining of complex parts. Known for its durability and advanced technology, this model provides exceptional performance and reliability in various industrial applications. Ideal for manufacturers seeking precision and productivity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Okuma Lathe LU-15MW

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Okuma Lathe LU-15MW

Create an account to install this asset package.

Maintenance Plans for Okuma Lathe Model LU-15MW

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Lathe Maintenacne

Change hydraulic oil in the hydraulic unit

Supply lubricating oil to the chip conveyor

Change cooling oil in the spindle cooling unit

Enter the hours on the Oil-air lubrication unit

If the hours on the Oil-air lubrication unit exceed 1000, replenish the unit

Sign off on the lathe maintenance

Initial 1 Monthly Lathe Maintenance

Check the bedways for level and straightness

Flush out the hydraulic power unit and change the hydraulic fluid

Change cooling oil in the spindle cooling unit

Saddle-Cross Slide Tapered Gib Adjustment

Warning: This procedure requires trained personnel with PPE!

Check for noticeable irregular feed movement

If irregular feed movement is noticed, proceed with the following steps

Remove the right and left saddle covers

Loosen the gib adjusting screw at the headstock side (left side)

Fully tighten and then return by a half turn the gib adjusting screw at the tailstock side (right side)

Tighten the gib adjusting screw at the headstock side (left side)

Enter the clearance measurement

Adjust the gibs for the cross-slide in the same manner

Headstock Alignment

Warning: This procedure requires trained personnel with PPE!

Loosen the headstock clamping screws (M20, 6 pcs.)

Align the headstock in A direction

After loosening the adjusting screw (b), secure the adjusting screw (a). This shifts the headstock in the A direction

Align the headstock in B direction

After loosening the adjusting screw (a), secure the adjusting screw (b). This shifts the headstock in the B direction

Carry out this adjustment while reading the dial indicator applied at the front end of the test piece

For Your Information: The Japanese Industrial Standard (JIS) specifies that the lathe should turn cylindrically to within 0.015 per 225 mm (0.0006 per 8.86 in.) of finishing length of work held in a chuck without the use of the tailstock center to hold the work

After the required accuracy is obtained, tighten the six headstock clamping screws. Note that the reading of the dial indicator applied at the test piece end must not change

Coolant Tank Cleaning

Cover at the side of the coolant tank removed

Coolant drawn out of the tank by the pump

Coolant tank pulled out to the right until the pump protrudes from the side cover, and pulled out to the front

Inside of the coolant tank cleaned

Filter cleaned

Coolant tank refilled after cleaning

Coolant tank not protruding from the front rail

Coolant tank installed correctly to prevent leakage

Sign off on the coolant tank cleaning

Parts for Okuma Lathe LU-15MW

Access the parts list for your equipment in MaintainX.

Pressure Gauge Talistock Manifold Block 1/2FP x 60 x 70 K

T019-400-003-24

Limit Switch Tailstock

E3019-891-017

AC Motor 22/15 kW (30/20 HP) Built-in Motor

E1006-288-025

High-speed Spindle AC Motor 22/18.5 kW

E1006-288-023

Door Interlock Limit Switch

E3012-891-001

Pressure Gauge Talistock Manifold Block 1/2FP x 60 x 70 K

T019-400-003-24

Limit Switch Tailstock

E3019-891-017

AC Motor 22/15 kW (30/20 HP) Built-in Motor

E1006-288-025

High-speed Spindle AC Motor 22/18.5 kW

E1006-288-023

Door Interlock Limit Switch

E3012-891-001

Pressure Gauge Talistock Manifold Block 1/2FP x 60 x 70 K

T019-400-003-24

Limit Switch Tailstock

E3019-891-017

AC Motor 22/15 kW (30/20 HP) Built-in Motor

E1006-288-025

High-speed Spindle AC Motor 22/18.5 kW

E1006-288-023

Door Interlock Limit Switch

E3012-891-001

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX