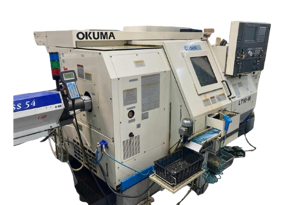

The Okuma Lathe LB25 is a high-precision CNC machine designed for efficient metalworking. Known for its robust construction and advanced features, this lathe is ideal for various machining applications, ensuring reliability and accuracy in production environments. Optimize your operations with the LB25's exceptional performance and durability.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Okuma Lathe LB25

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Okuma Lathe LB25

Create an account to install this asset package.

Maintenance Plans for Okuma Lathe Model LB25

Integrate maintenance plans directly into your work orders in MaintainX.

Tensioning Belts

Adjusting Belt Tension by Using A Tension Meter (Optional)

Loosen bolt A

Turn the tension adjusting bolt

Adjust belt tension using a tension meter (optional) by referring to Table 4-2

After adjusting the belt tension, tighten bolt A to clamp the motor base

How to Use Tension Meter

Provide deflection ô at the center of the belt span and read the tension load 'F'

When installing a new belt, or readjusting the present belt, the tension should be adjusted to the values shown in Table 4-2 below

Sign off on the tensioning belts procedure

Coolant Tank Cleaning

Procedure to Clean the Separately Installed Coolant Tank

Remove the front cover

Remove the cover at the side of the coolant pump

Draw the coolant out of the tank by the pump

Pull out the coolant tank to the right until the pump protrudes from the side cover, and pull it out to the front

Clean inside the coolant tank

Clean the filter

After cleaning the tank, reinstall the coolant tank

Warning: The coolant tank must not protrude from the front rail. If the coolant tank is not installed correctly, coolant will leak

Alignment of Headstock

Warning: This procedure requires trained personnel with PPE!

Japanese Industrial Standard (JIS) specifies that the lathe should turn cylindrically to within 0.015 per 225 mm (0.00059 per 8.86 in.) of finishing length of work held in a chuck without the use of tailstock center to hold the work.

Mount the aligning fixtures (A) to the front of the headstock with screws B (M12, 1 pc .~ each)

Tighten screws C (M12, 2 pcs.) lightly to the base

Screw in screws D (M12, 2 pcs.) to fixture (A) until they contact the base

Loosen screws E and F (M24, 6 pcs.)

Adjust the alignment of the headstock with screws C and D

After completing the adjustment, tighten screws E and F, then remove fixtures (A)

Sign off on the alignment of the headstock

6 Months Lathe Inspection

Change hydraulic oil in the hydraulic unit

Supply lubricating oil to the chip conveyor

Check belt tension

Sign off on the 6 months lathe inspection

Lathe Lubrication

Warning: Only use specified lubricating oil and coolant.

Is the correct lubricating oil being used?

Is the correct coolant being used?

If incorrect oil or coolant is used, it may cause corrosion or lubrication failure.

Check for potential issues if non-recommended coolant is used

If any issues are found, avoid using the coolant.

Check the oil level in the tank.

For normal oil consumption amount, refer to 1-2 in this section.

Prior to shipment, the oil and coolant tanks are flushed out and must be refilled during the initial installation.

Parts for Okuma Lathe LB25

Access the parts list for your equipment in MaintainX.

Electromagnetic Brake BXL-08-10-A-17

E2131-835-010

Dester Block DS8Z

H0019-0002-44

Pressure Gauge OPG-DT1/4-¢40 × 70K

T019-400-003-45

Wiper Wiper edge

H1023-0020-65-1

Limit Switch 1LSI-J

E3012-891-001

Electromagnetic Brake BXL-08-10-A-17

E2131-835-010

Dester Block DS8Z

H0019-0002-44

Pressure Gauge OPG-DT1/4-¢40 × 70K

T019-400-003-45

Wiper Wiper edge

H1023-0020-65-1

Limit Switch 1LSI-J

E3012-891-001

Electromagnetic Brake BXL-08-10-A-17

E2131-835-010

Dester Block DS8Z

H0019-0002-44

Pressure Gauge OPG-DT1/4-¢40 × 70K

T019-400-003-45

Wiper Wiper edge

H1023-0020-65-1

Limit Switch 1LSI-J

E3012-891-001

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX