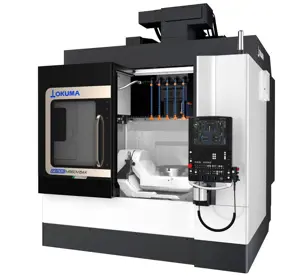

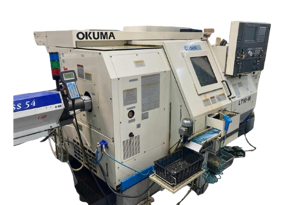

The Okuma Lathe LOC650 is a high-performance CNC lathe designed for precision machining. Known for its reliability and advanced features, this model is ideal for various industrial applications, ensuring optimal productivity and efficiency in manufacturing processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Okuma Lathe LOC650

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Okuma Lathe LOC650

Create an account to install this asset package.

Maintenance Plans for Okuma Lathe Model LOC650

Integrate maintenance plans directly into your work orders in MaintainX.

Adjustment of tapered Gibs on Saddle and Cross-slide

Warning: This procedure requires trained personnel with PPE!

Check for noticeable irregular feed movement

Upper Z-axis slide (carriage or saddle) adjustment

Covers from the left- and right-hand sides of the Z-axis slide removed

Wiper cases removed

Gib position adjusted by means of the gib adjusting screws

Lower Z-axis slide (carriage or saddle) adjustment

Wiper cases from the left- and right-hand sides of the Z-axis slide removed

Gib position adjusted by means of the gib adjusting screws

Tailstock Alignment

Warning: This procedure should be performed by trained personnel only.

Loosen the four upper body clamp bolts.

Adjust the tailstock laterally, using the center alignment screw.

After adjustment, re-tighten the screws and bolts in position.

Sign off on the tailstock alignment

Adjustment of Turret Index Speed

CAUTION: Improper adjustment may result in trouble with the turret index driving system. Please adjust carefully.

V12 Turret Adjustment

Cover removed

Lock nut of the turret index speed adjusting screw removed

Adjusted turret index speed (should be about 12 seconds/rotation)

V8 Turret Adjustment (Two-Turret Model)

Followed the same procedure as adjusting V12 turret

Adjusted turret index speed (should be about 8 seconds/rotation)

Sign off on the turret index speed adjustment

Filters Cleaning

Warning: NEVER USE THINNER OR TRICHLEN (trichloroethylene) SHOWING HIGH VOLATILE CHARACTERISTICS when cleaning the tank and the filter.

Pump removed?

Suction filter cleaned?

Pump reinstalled at the original location?

Oil discharged from the case?

Paper element replaced?

Sign off on the filter cleaning

Cleaning Coolant Tank

Draw the coolant out of the tank by the pump into a proper storage container

Flush out the tank completely to remove the coolant remaining in the tank through the drain hole provided

Remove the perforated metal plate and clean it

Clean out the tank

Remove the strainer from the suction line of the pump

Clean the strainer

Refill the coolant tank

Is the machine equipped with chip conveyor?

Remove the rail support

Parts for Okuma Lathe LOC650

Access the parts list for your equipment in MaintainX.

Warning against X-axis turret falling

H1090-1018-44 (2S)

Warning against X-axis turret falling

H1090-1018-53 (1S)

Warning against fire

H1090-1018-35-1

Caution against workpiece projection

H1090-1018-83

Caution for cover removal

H1090-1018-33

Warning against X-axis turret falling

H1090-1018-44 (2S)

Warning against X-axis turret falling

H1090-1018-53 (1S)

Warning against fire

H1090-1018-35-1

Caution against workpiece projection

H1090-1018-83

Caution for cover removal

H1090-1018-33

Warning against X-axis turret falling

H1090-1018-44 (2S)

Warning against X-axis turret falling

H1090-1018-53 (1S)

Warning against fire

H1090-1018-35-1

Caution against workpiece projection

H1090-1018-83

Caution for cover removal

H1090-1018-33

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX