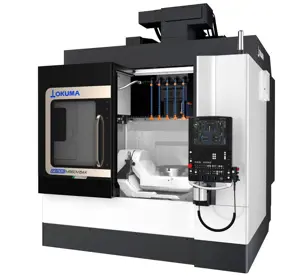

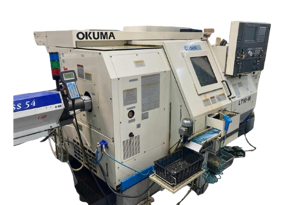

The Okuma Lathe LB15 is a high-precision CNC machine designed for efficient metalworking. Known for its durability and advanced features, this lathe model excels in producing intricate parts with exceptional accuracy, making it a preferred choice for manufacturers seeking reliability and performance.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Okuma Lathe LB15

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Okuma Lathe LB15

Create an account to install this asset package.

Maintenance Plans for Okuma Lathe Model LB15

Integrate maintenance plans directly into your work orders in MaintainX.

Headstock Alignment

Warning: This procedure requires trained personnel with PPE!

Secure the headstock alignment fixture at the front of the headstock with three M12 screws

Tighten two M12 screws to the base lightly

Screw in two M12 screws into the fixture until they touch the base

Loosen six M24 screws

Align the headstock with screws

After completing headstock alignment, secure screws then remove the fixture

Sign off on the headstock alignment

1 Daily Lathe Service

Check oil level through the oil level gauges in the hydraulic power unit

Check oil level in the guideway lube oil tank

Check oil level in the headstock tube oil tank

Check oil flow through the oil window at the front of the headstock

Check gripping pressure of the hydraulic power chuck through the oil pressure gauge

Check working pressure for the turret drive through the oil pressure gauge

Greasing to power chuck jaw slide surfaces

Check lubricated conditions of bed and saddle slideway surfaces

Check the bedways for level and straightness

Coolant Tank Cleaning

Clean the coolant tank integral with the machine base casting

Draw the coolant out of the tank by the pump into a proper container

Remove the perforated metal plate and clean it

Clean out the tank

Remove the strainer from the suction line of the pump

Clean the strainer

Refill the coolant tank

Sign off on the coolant tank cleaning

Filter Cleaning

Warning: Handle the filter element carefully to avoid damage

Filter element removed from casing

Cotton thread unwound from the element

Two layers of all-wool white mousseline renewed

Inside and outside of the element cleaned with solvent naphtha or petroleum benzine

Never use a wipe cloth on the element

Sign off on the filter cleaning

Turret Indexing Time Check

Warning: This procedure requires trained personnel!

Turret manually indexed

Turret indexing done in MDI mode operation

Display page switched to CHECK DATA page

Accessed the page on which the AXIS DATA is displayed

Enter the turret indexing time displayed at X column

Enter the turret indexing time displayed at Z column

Are the values at X and Z columns identical?

Turret indexing from one station to the next attempted

Parts for Okuma Lathe LB15

Access the parts list for your equipment in MaintainX.

Pressure Gauge Hydraulic Power Unit

T019-490-000-83

Belt Main Spindle Drive Motor 5.57/5.7 kW

M119-9066-39

Solenoid Valve for V12 Turret Index

F9001-445-000-07

Upper Right Cross-slide Wiper

H1023-0007-93

Dester Plunger Cross-slide

H0012-0004-72

Pressure Gauge Hydraulic Power Unit

T019-490-000-83

Belt Main Spindle Drive Motor 5.57/5.7 kW

M119-9066-39

Solenoid Valve for V12 Turret Index

F9001-445-000-07

Upper Right Cross-slide Wiper

H1023-0007-93

Dester Plunger Cross-slide

H0012-0004-72

Pressure Gauge Hydraulic Power Unit

T019-490-000-83

Belt Main Spindle Drive Motor 5.57/5.7 kW

M119-9066-39

Solenoid Valve for V12 Turret Index

F9001-445-000-07

Upper Right Cross-slide Wiper

H1023-0007-93

Dester Plunger Cross-slide

H0012-0004-72

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX