Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

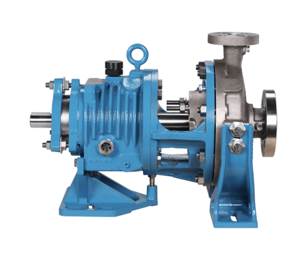

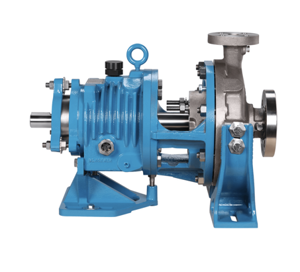

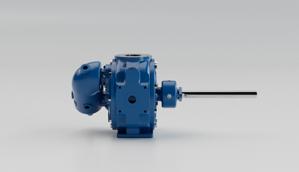

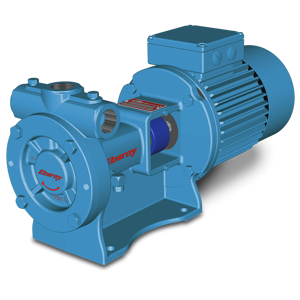

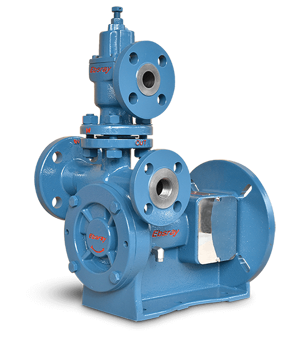

Manual for Blackmer Seal-less Internal Gear Pump (copy) E1-2 CARBON STEEL .

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Blackmer Seal-less Internal Gear Pump (copy) E1-2 CARBON STEEL .

Create an account to install this asset package.

Maintenance Plans for Blackmer Seal-less Internal Gear Pump (copy) Model E1-2 CARBON STEEL .

Integrate maintenance plans directly into your work orders in MaintainX.

Relief Valve Pressure Setting Replacement

Warning: The E1-2 thru E1-82 E Series relief valves are not externally adjustable.

The setting is adjusted by changing the poppet and spring.

Obtained a new poppet and spring for the desired relief-valve setting?

Disassembled relief valve?

Reassembled the relief valve using the new poppet and spring?

Sign off on the relief valve pressure setting replacement

Outer Ball Bearing Replacement

Position the outer drive assembly on blocks in a suitable press with the shaft facing upward

Remove the snap ring from its groove in the shaft

Press the shaft downward until the outer bearing disengages from the shaft

Remove the outer ring assembly with shaft and inner bearing attached, wave spring and outer bearing

Remove the inner bearing from the shaft with a suitable gear puller

Apply a light oil to the shaft and press the new inner bearing into the shaft. The new bearing inner race should be flush with the outer ring. Be careful to avoid disrupting the shaft position relative to the outer ring

Insert the wave spring into the inner bearing counter-bore of the magnet housing /bearing housing

Insert the outer ring/shaft/inner bearing assembly into the magnet housing/bearing housing

Press the outer bearing onto the shaft until the distance from the end of the shaft to the face of the bearing

Idler Bushing Replacement

Remove the old bushing by pressing it out of the idler. It is not unusual for carbon graphite bushings to crack or break apart during removal

Inspect the idler bore for any damage. Any small scratches or nicks must be filed smooth before installing the new bushing

Press the new idler bushing into the idler leading with the tapered edge

Bushing is in its proper location when both ends of the bushing are flush or slightly recessed from the idler face

Sign off on the idler bushing replacement

Port Orientation and Shaft Rotation Replacement

Warning: This procedure requires trained personnel with PPE!

Direction of shaft rotation changed from RT to LT?

Discharge and suction positions relative to the casing and head changed?

Cooling circuit plugs moved?

Relief valve disassembled (if equipped)?

Pumping chamber disassembled?

Casing orifice plug and casing block-off plug removed?

Casing orifice plug installed behind the DISCHARGE port (if required)?

Head block-off plug moved to the DISCHARGE side (if equipped)?

Port Orientation Replacement

Instructions for changing from RT to TL without changing the direction of shaft rotation

Check if the pump is equipped with a relief valve

If the pump is equipped with a relief valve, follow the next steps

Disassemble the relief valve

Disassemble the pumping chamber

Assemble pumping chamber in the new orientation

Assemble relief valve

Sign off on the port orientation replacement

Parts for Blackmer Seal-less Internal Gear Pump (copy) E1-2 CARBON STEEL .

Access the parts list for your equipment in MaintainX.

Head for Models with RV

HD39

Head for Models without RV

HD6

Head for Models with Head Jacket

HD10

Casing 1 1/2" ANSI 150# Ports (90° orientation)

CS7

Casing DN40 PN16 Ports (90° orientation)

CS7D

Head for Models with RV

HD39

Head for Models without RV

HD6

Head for Models with Head Jacket

HD10

Casing 1 1/2" ANSI 150# Ports (90° orientation)

CS7

Casing DN40 PN16 Ports (90° orientation)

CS7D

Head for Models with RV

HD39

Head for Models without RV

HD6

Head for Models with Head Jacket

HD10

Casing 1 1/2" ANSI 150# Ports (90° orientation)

CS7

Casing DN40 PN16 Ports (90° orientation)

CS7D

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX