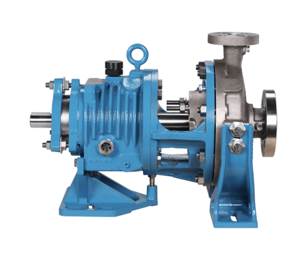

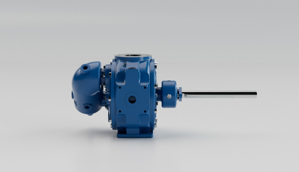

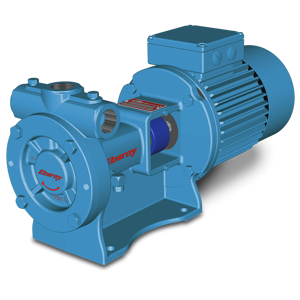

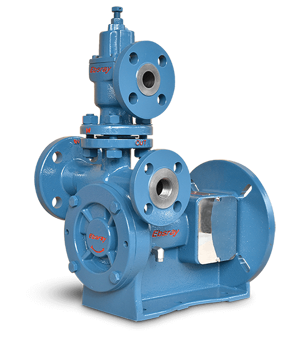

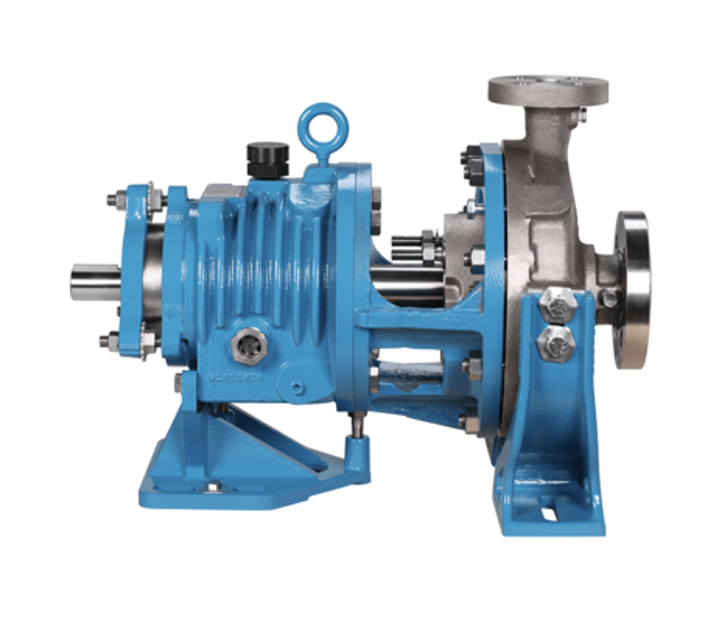

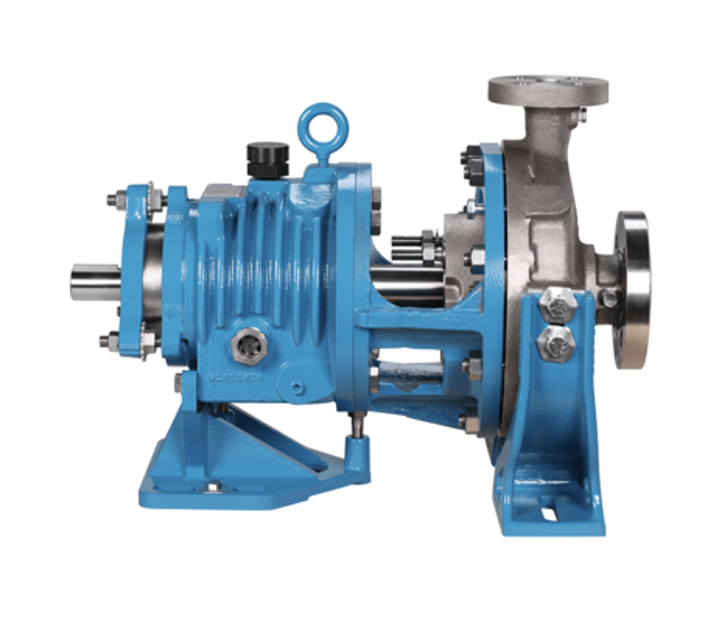

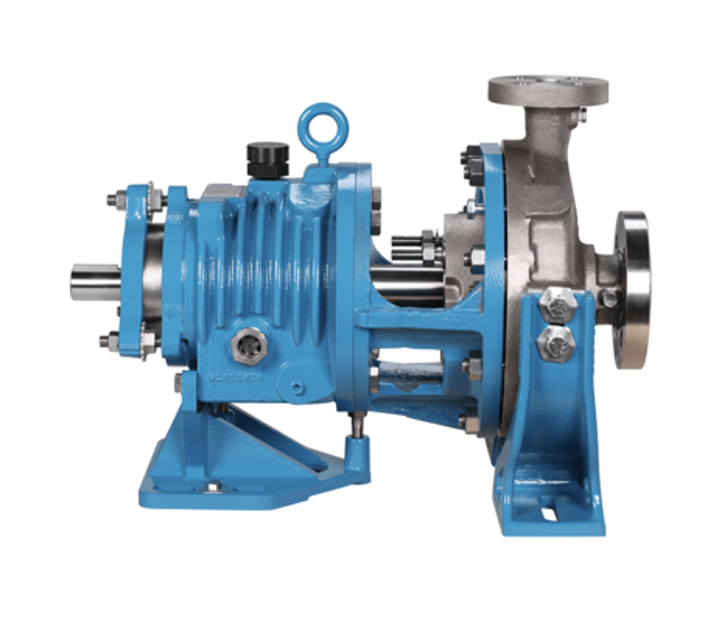

The Blackmer Centrifugal Pump A2x3-10 is a reliable and efficient industrial pump designed for various fluid transfer applications. Known for its robust construction and ease of maintenance, this model ensures optimal performance and longevity in demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Blackmer Centrifugal Pump A2x3-10

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Blackmer Centrifugal Pump A2x3-10

Create an account to install this asset package.

Maintenance Plans for Blackmer Centrifugal Pump Model A2x3-10

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Bearing Grease Lube Replacement

For vertical installations bearing grease must be used in place of oil

Use a premium quality lithium grease, having an NLGI 2 or 3 consistency and a base oil viscosity of 68 centistokes minimum at 40°C

When reassembling a pump, the bearings are best pre-greased after assembly onto the shaft

The bearings should be packed full with grease and the bearing housing adjacent to the bearings packed one third to one half full

NOTICE: Never mix greases of different consistencies

Please note that vertical pumps are all grease lubed and that bearings are greased at the factory, thus no additional grease at installation is required

Re-greasing Intervals: For back to back angular contact, single and double row bearings, add several shots of grease from a grease gun at following intervals

At 950 RPM, add grease every 5500 hours

At 1180 RPM, add grease every 5000 hours

Pump Overhaul

CAUTION! Always use a lifting device capable of supporting the full weight of the pump components or assemblies

WARNING! Personal protective equipment must be worn if there is a potential for handling hazardous or toxic materials. Fluid must be handled and disposed of in accordance with local and national regulations. Pump must be isolated by closing suction and discharge valves before working on the pump

WARNING! Lock-out power to the driver before working on the pump. Failure to properly lock-out driver could result in accidental start, causing personal injury

CAUTION! Do not adjust or disassemble any pressure containing component or shaft seal prior to depressurizing the primary and auxiliary fluid systems. This will ensure that no hazardous or high pressure fluid is ejected that may cause personal injury or equipment damage

Remove the Power End Assembly

Lockout driver and tag it

If pump has a C-frame adapter and power is rigid piped, disconnect the power connection at driver

Remove the coupling guard

Disconnect the coupling between the pump and the driver shafts by removing the spacer piece between the hubs. If the pump has a motor adapter and the driver is suspended and wired with flexible conduit, the coupling will not have to be removed

12 Monthly Bearing Oil Lube Replacement

Warning: This procedure requires trained personnel with PPE!

Pump bearing frame filled with high quality, anti-foaming turbine oil containing rust and oxidation inhibitors

Bearing temperature reading

Is the bearing temperature below 180° F (82° C)?

Select the type of oil used

Last oil change date

Are there severe environmental conditions, such as dust, moisture and corrosive atmospheres?

If severe environmental conditions are present, oil should be changed more frequently

Sign off on the bearing oil lube replacement

Parts for Blackmer Centrifugal Pump A2x3-10

Access the parts list for your equipment in MaintainX.

Gage Tap Plug

628343

Gage Tap Plug

350664

Adaptor Stud

098281

Casing Assembly 150FF

090801

Casing Assembly 150RF

628523

Gage Tap Plug

628343

Gage Tap Plug

350664

Adaptor Stud

098281

Casing Assembly 150FF

090801

Casing Assembly 150RF

628523

Gage Tap Plug

628343

Gage Tap Plug

350664

Adaptor Stud

098281

Casing Assembly 150FF

090801

Casing Assembly 150RF

628523

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX