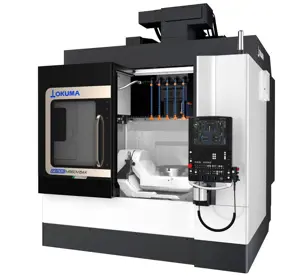

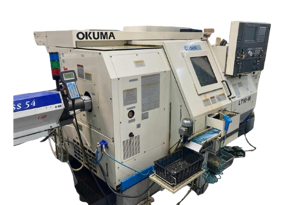

The Okuma Vertical Machining Center Cadet is a high-performance CNC machine designed for precision machining tasks. Known for its reliability and advanced technology, this model excels in various industrial applications, ensuring optimal productivity and efficiency in manufacturing processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Okuma Vertical Machining Center Cadet

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Okuma Vertical Machining Center Cadet

Create an account to install this asset package.

Maintenance Plans for Okuma Vertical Machining Center Model Cadet

Integrate maintenance plans directly into your work orders in MaintainX.

3 Monthly Cooling Unit Cleaning

Warning: The CNC unit incorporates electronic devices which are susceptible to moisture, oil, dirt, dust, and chips, and also elevated temperatures in the enclosure caused by clogging of filters in the cooling unit.

Daily inspection and maintenance of the CNC unit is important.

Every Three-month Inspection

Does the cooling unit mounted at the control enclosure door operate to blow air hard?

If the filter is clogged, clean it.

Is the filter clean now?

Sign off on the cooling unit cleaning

2000 Hourly Vertical Machining Center Lubrication

Note: The Mate U-10 control incorporates a 2000 hour PLC timer which monitors the combined X,Y and Z axis movements over time. When this combined total equals 2000 hours, the following Alarm D will occur. 4729:

Axis lube maintenance warning

This warning indicates that the axes have been in movement for a combined 2000 hours. Please lubricate axes according to maintenance manual.

This Alarm D will warn the operator to apply grease to the locations described in the previous page.

Warning: Do not ignore this alarm! It is very important that the 2000 hour lubrication be performed.

Reset of Alarm 4729

After the 2000-hour lubrication is performed, the 4729 alarm must be reset in order to clear the alarm display and restart the PLC counter.

Enter the MC User Parameter area and page down until the following screen is located:

1. Set the "Axis lube maintenance reset" parameter to "1".

Regulator, Lubricator, And Air Filter Adjustment

To adjust the air control unit (regulator, lubricator and air filter) mounted at the right rear side of the machine, follow the procedure below.

(1) Adjustment of the Regulator Pressure

System pressure: 0.55 MPa [5.5 kgf/cm2 (78.2 psi)]

To increase the pressure, pull down the knob and turn it in the clockwise direction.

To decrease the pressure, pull down the knob and turn it in the counterclockwise direction.

(2) Refilling oil to the Oil Lubricator and Adjustment

a) Refilling

TURN THE COMPRESSED AIR SUPPLY OFF.

Remove the oil reservoir (bowl) and refill oil as needed.

Floppy Disk Drive Cleaning

(1) Cleaning the 3.5" Floppy Disk Drive Head

A dirty read/write head may sometimes cause the floppy disk read/write error. Clean the head using a head cleaning disk.

The head cleaning disk may be either a market product or the one ordered from Okuma.

Okuma part No .: E0241-602-003

Okuma part name: Floppy head cleaning disk FCD-3.5W (Maker: Nippon Microcoating)

(2) Head Cleaning Procedure

To clean the head with the above cleaning disk, proceed as follows. When using the other maker's cleaning disk, follow the attached instructions.

(a) Insert the head cleaning disk into the floppy disk drive unh.

(b) Drive the cleaning disk using the disk initializing function.

1 Daily Control Enclosure and Operation Box Inspection

Warning: The CNC unit incorporates electronic devices which are susceptible to moisture, oil, dirt, dust, and chips, and also elevated temperatures in the enclosure caused by clogging of filters in the cooling unit. Therefore, daily inspection and maintenance of the CNC unit is important.

Visually check the control enclosure and the operation box for adhesion of water, oil, dust, and chips

Check the cooling unit filter for clogging

If the control enclosure and the operation box are dirty, clean them.

Check the inside of the control enclosure and the operation box.

Sign off on the daily control enclosure and operation box inspection

Parts for Okuma Vertical Machining Center Cadet

Access the parts list for your equipment in MaintainX.

Floppy head cleaning disk FCD-3.5W

E0241-602-003

Floppy head cleaning disk FCD-3.5W

E0241-602-003

Floppy head cleaning disk FCD-3.5W

E0241-602-003

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX