Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

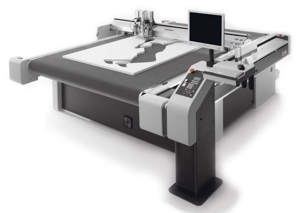

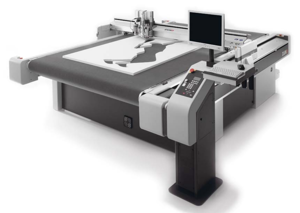

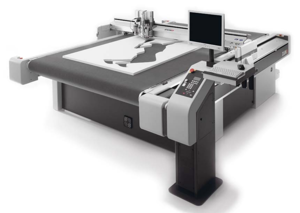

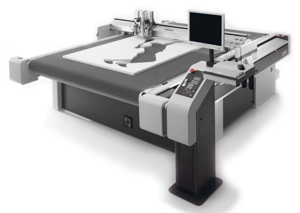

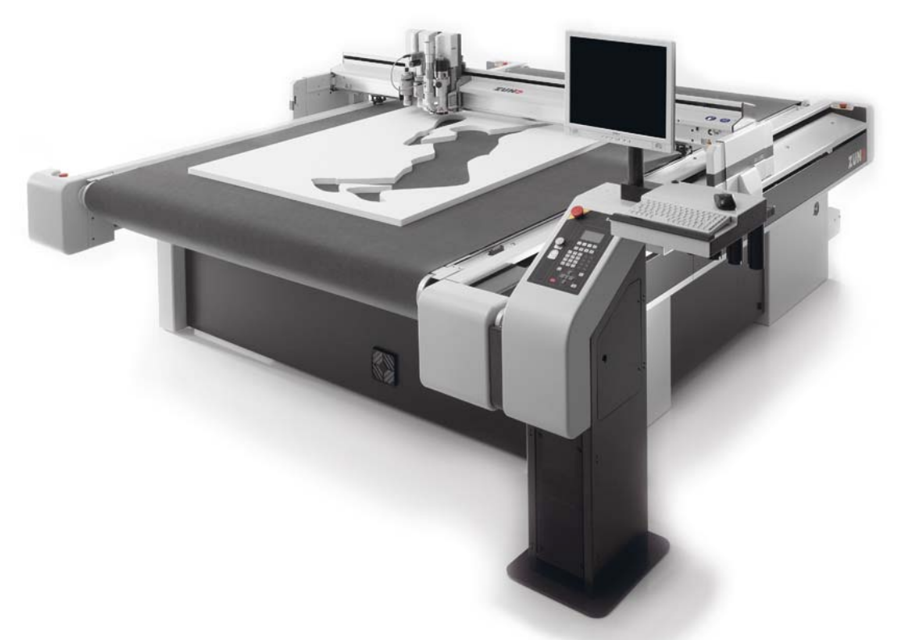

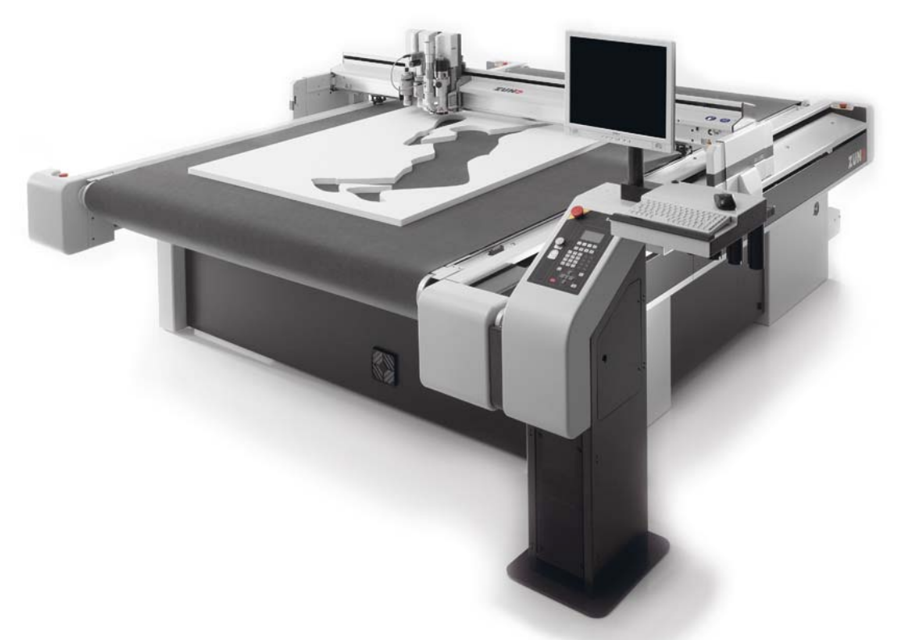

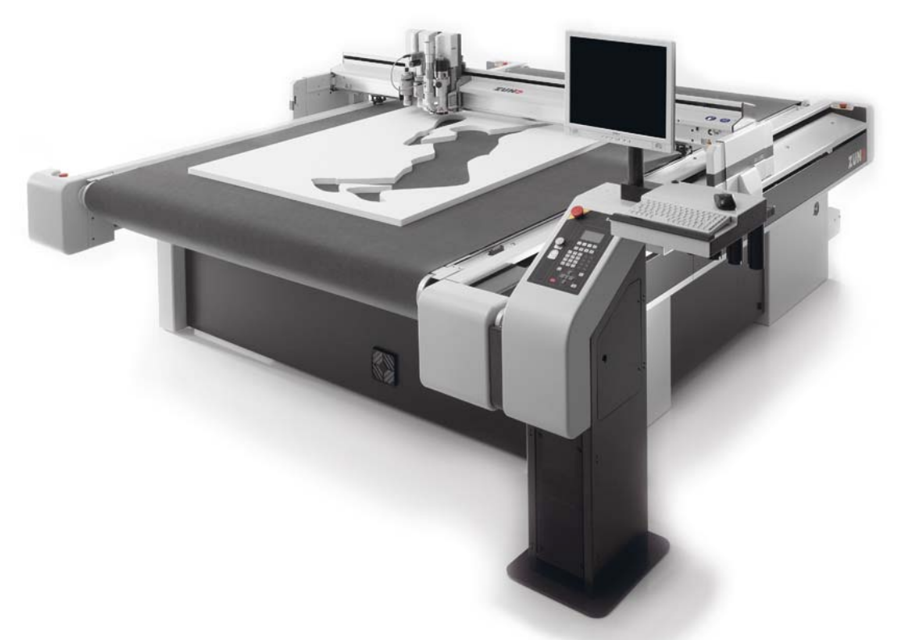

Zünd Systemtechnik Digital Flatbed Cutter 3XL-1600

Create an account to install this asset package.

Maintenance Plans for Zünd Systemtechnik Digital Flatbed Cutter Model 3XL-1600

Integrate maintenance plans directly into your work orders in MaintainX.

1 Weekly Digital Flatbed Cutter Maintenance

This maintenance procedure is for the basic unit only. For modules, tool inserts and options, refer to the respective operating manual.

Maintenance jobs that operators can carry out themselves are indicated. No special tools are required for these jobs.

All other jobs must be undertaken only by personnel authorised by Zünd or by Zünd Systemtechnik Customer Services or by contractual partners authorised by Zünd Systemtechnik.

Do not exceed the specified maintenance and cleaning intervals. You can shorten these intervals if necessary at your own discretion.

Clean rubber cushions/needle cushions of the feed elements

Clean feed guide rail

Check the compressor oil level, if necessary top up oil according to specifications

1 Monthly Compressor Maintenance

General!

This chapter describes (in tabular form) all the maintenance jobs which are required for the machine

The maintenance list only affects the basic unit. Maintenance activities for modules, tool inserts and options can be found in the respective operating manual

Maintenance jobs that operators can carry out themselves are specially indicated and are described in more detail in this chapter. Important!

In general, no special tools are required for maintenance jobs that operators can carry out themselves

All other jobs must be undertaken only by personnel authorised by Zünd or by Zünd Systemtechnik Customer Services or by contractual partners authorised by Zünd Systemtechnik

Important!

Do not exceed the specified maintenance and cleaning intervals. You can shorten these intervals if necessary at your own discretion

Check water separator and drain water if necessary

1 Monthly Axis Drive Maintenance

General!

– This chapter describes (in tabular form) all the maintenance jobs which are required for the machine

– The maintenance list only affects the basic unit. Maintenance activities for modules, tool inserts and options can be found in the respective operating manual

– Maintenance jobs that operators can carry out themselves are specially indicated and are described in more detail in this chapter. Important!

In general, no special tools are required for maintenance jobs that operators can carry out themselves

• All other jobs must be undertaken only by personnel authorised by Zünd or by Zünd Systemtechnik Customer Services or by contractual partners authorised by Zünd Systemtechnik

Important!

Do not exceed the specified maintenance and cleaning intervals. You can shorten these intervals if necessary at your own discretion

- Clean X axis guide rails!

Conveyor Belt Maintenance

General!

– This chapter describes (in tabular form) all the maintenance jobs which are required for the machine

– The maintenance list only affects the basic unit. Maintenance activities for modules, tool inserts and options can be found in the respective operating manual

– Maintenance jobs that operators can carry out themselves are specially indicated and are described in more detail in this chapter. Important!

In general, no special tools are required for maintenance jobs that operators can carry out themselves

• All other jobs must be undertaken only by personnel authorised by Zünd or by Zünd Systemtechnik Customer Services or by contractual partners authorised by Zünd Systemtechnik

Important!

Do not exceed the specified maintenance and cleaning intervals. You can shorten these intervals if necessary at your own discretion

- Undoing the tensioning screws!

1 Monthly Digital Flatbed Cutter Draining

Warning: Only authorized personnel should perform this procedure.

Warning: The condensation liquid from the water separator is contaminated with oil. Dispose of it correctly according to the specific national regulations.

Main switch of the maintenance unit set to Off

Container held under the drain

Drain screw opened

Liquid allowed to drip into the container

Drain screw shut

Sign off on the procedure

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX