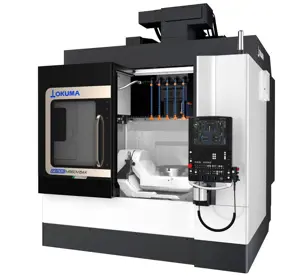

The Okuma Vertical Machining Center MC-V4020 is a high-performance CNC machine designed for precision machining tasks. Known for its reliability and advanced features, this model excels in various industrial applications, ensuring optimal productivity and efficiency in manufacturing processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Okuma Vertical Machining Center MC-V4020

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Okuma Vertical Machining Center MC-V4020

Create an account to install this asset package.

Maintenance Plans for Okuma Vertical Machining Center Model MC-V4020

Integrate maintenance plans directly into your work orders in MaintainX.

Floppy Disk Drive Cleaning

Warning: Excessive head cleaning will damage the floppy disk unit head. Limit cleaning to once in three months and do not exceed four times a month.

Enter the part number of the head cleaning disk used

Enter the part name of the head cleaning disk used

Is the head cleaning disk inserted into the floppy disk drive unit?

Drive the cleaning disk using the disk initializing function.

Did you press EDIT AUX key?

Did you press the function key [F8](EXTEND)?

Did you press the function key [F2] (INIT)?

Enter the initialization command

1 Daily Control Enclosure and Operation Box Inspection

Warning: The CNC unit incorporates electronic devices which are susceptible to moisture, oil, dirt, dust, and chips, and also elevated temperatures in the enclosure caused by clogging of filters in the cooling unit. Therefore, daily inspection and maintenance of the CNC unit is important.

Visually check the control enclosure and the operation box for adhesion of water, oil, dust, and chips

Check the cooling unit filter for clogging

If the control enclosure and the operation box are dirty, clean them.

Check the inside of the control enclosure and the operation box.

Sign off on the daily control enclosure and operation box inspection

The Battery Replacement

Warning: Battery change requires trained personnel with PPE!

Warning: The capacitor can retain the disk memory data for one hour. Change the battery within this period.

Battery Life Warning: Alarm-D Memory board/battery change

Battery Life Warning: Alarm-A Memory board/battery hurry exchange

Battery Life Warning: Alarm-P Memory board/battery life

Procedure for Battery Replacement

Back up the system data and the user file

Prepare the tools necessary for changing the battery

Place the CNC in the install mode

3 Monthly Cooling Unit Cleaning

Warning: The CNC unit incorporates electronic devices which are susceptible to moisture, oil, dirt, dust, and chips, and also elevated temperatures in the enclosure caused by clogging of filters in the cooling unit.

Therefore, daily inspection and maintenance of the CNC unit is important.

Every Three-month Inspection

Does the cooling unit mounted at the control enclosure door operate to blow air hard?

If the filter is clogged, clean it.

Sign off on the cooling unit cleaning

1 Daily Vertical Machining Center Maintenance

Daily Tasks

Check incoming air pressure, 0.55 MPa [5.5 kgf/cm (78.2 psi)]

Check oil level of the pneumatic lubricator

Clean the tapered bore of the spindle

Remove and discharge chips from machine

Weekly Tasks

Clean the air filter

Parts for Okuma Vertical Machining Center MC-V4020

Access the parts list for your equipment in MaintainX.

Floppy head cleaning disk FCD-3.5W

E0241-602-003

Floppy head cleaning disk FCD-3.5W

E0241-602-003

Floppy head cleaning disk FCD-3.5W

E0241-602-003

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX