Condition-Based Maintenance Software

Condition-based maintenance that’s easy to adopt

Our clients using MaintainX report

Generate action, not just alerts

Alerts don’t keep your facility running—actions do. When MaintainX detects faults, it generates and assigns a work order with all the right steps. This helps your team act faster to prevent downtime.

Resolve issues faster with AI

Don’t leave technicians guessing when alarms go off. MaintainX CoPilot provides instant context from manuals, work history, and machine data, helping your frontline team troubleshoot and repair faster.

Connect your systems quickly and securely

Automate inspections using real-time data from SCADA, MQTT brokers, sensor platforms, and more. Connect the data to MaintainX in minutes using pre-built integrations.

Reduce costs by doing work only when needed

Save time and money on manual inspections and premature PMs. Keep your teams focused on the assets that need attention, and minimize downtime without overspending on parts and labor.

Monitor your assets in one place

Get the full picture on machine status, health, and run time where your team is already working. Monitor your production lines without switching between multiple systems.

Award-winning software you can trust

Not convinced?

See what customers have to say

Condition-based maintenance software FAQs

What is condition-based maintenance software, and how does it differ from preventive maintenance?

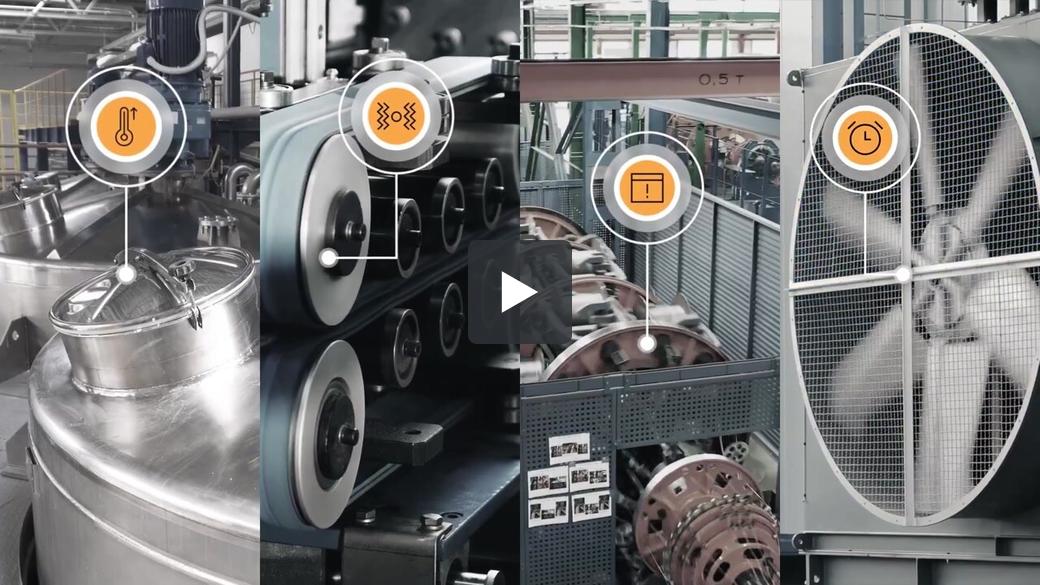

Condition-based maintenance (CBM) software uses real-time condition monitoring (like vibration, temperature, or pressure readings) to identify signs of potential signs equipment failure and trigger corrective maintenance actions. While CBM and preventive maintenance are both forms of proactive maintenance, preventive maintenance relies on fixed intervals, like time or usage. CBM focuses maintenance resources based on which equipment is most likely to need them, improving equipment reliability and asset performance while reducing maintenance costs, emergency repairs, and unplanned downtime.

How can CMMS software support a condition-based maintenance program for critical assets?

A CMMS centralizes asset management records, maintenance history, SOPs, and parts inventory tracking. It also ingests real-time data from SCADA, MQTT brokers, and sensor platforms. It then uses all this data to automatically generate work orders when thresholds are crossed. This allows maintenance teams to respond to early signs of failure faster and ensures fewer false alarms. CMMS software also helps organizations track key performance indicators (KPIs) for condition-based maintenance programs so they can adjust thresholds and response procedures to optimize maintenance effectiveness and asset performance.

How does condition-based maintenance help reduce maintenance costs and costly downtime?

CBM allows maintenance teams perform work only when needed, helping them avoid unnecessary inspections while making sure they don't miss signs of equipment failure. This reduces maintenance costs while improving asset performance. Automated alerts and work orders also drive faster responses to performance issues, preventing costly breakdowns and minimizing unplanned outages. Better planning, accurate data, and smarter inventory management cut labor and parts spend while boosting uptime.

What role does real-time monitoring play in improving equipment reliability through CBM?

Real-time monitoring captures continuous data on asset performance, which tells maintenance teams if a piece of equipment is operating as it should be or if there's something wrong with it. If the data captured by ongoing monitoring indicates signs of failure for a prolonged time, it will trigger predefined maintenance tasks, which helps to reduce mean time to repair (MTTR), extend mean time between failures (MTBF), and strengthen asset reliability.

Can condition monitoring software help identify potential failure and prevent unplanned outages?

Yes. Condition monitoring software captures information about the performance of assets, whether it's how much a conveyor belt is vibrating or the temperature of a motor, to detect abnormal patterns and risk. If an issue is detected, corrective actions are automatically planned and scheduled, enabling proactive maintenance actions that prevent unplanned downtime and costly failures.

How do maintenance teams use sensor data to track critical parameters and monitor asset health?

Teams connect sensors, PLCs, and SCADA systems to their CMMS software via pre-built integrations or MQTT. They define thresholds and rules for critical assets, visualize equipment health in dashboards, and automatically create work orders with clear steps, parts, and safety checks. Asset health trends and maintenance history inform root-cause analysis and continuous improvement.

What are the benefits of using CMMS software to automate alerts based on equipment condition data?

Automated alerts reduce manual monitoring and ensure rapid, accountable responses. Benefits include fewer missed alarms, prioritized queues, audit trails, mobile notifications, faster approvals, and improved technician productivity, which all drive timely completion and prevent costly downtime.

How can CBM be used to optimize maintenance strategies and enhance operational efficiency?

CBM can be used in combination with preventive and predictive maintenance to match maintenance strategies to asset criticality. Preventive maintenance can be used when maintenance intervals are predictable and effective to reduce downtime on critical assets. Condition-based maintenance and predictive maintenance can be used on critical assets that have reliable failure modes that can be tracked effectively with meters, sensors, or even machine learning. When combined on the right assets, the result is an optimized maintenance management program that leads to higher operational efficiency, better resource allocation, and sustained improvements in maintenance operations.

Can a CMMS help analyze data from vibration sensors and high-frequency sound waves for early fault detection?

Yes. A CMMS consolidates and visualizes sensor streams, stores baselines, and applies rule-based or machine learning anomaly detection from integrated analytics. When abnormal signatures appear, it can trigger automated alerts and pre-populated work orders, ensuring timely, data-driven decisions.

How does condition-based maintenance improve technician productivity and resource allocation?

Condition-based maintenance schedules work when it’s needed, not on fixed intervals, so resources flow to the assets that matter most. Real-time condition data triggers prioritized work orders, allowing planners to assign the right technicians, skills, and parts at the right time. By cutting low-value PMs and routine rounds, teams spend more wrench time on high-impact tasks, increase first-time fix rates, and align maintenance windows with production. The result is smarter resource allocation, fewer emergency callouts, and technicians focused on work that maximizes equipment uptime and reliability.

How can condition-based monitoring be used to support regulatory compliance and risk mitigation efforts?

Digital records of inspections, alarms, work orders, sign-offs, and calibration tasks create a complete audit trail. Standardized procedures, safety checks, and photo/scan capture reduce safety risks and support regulatory compliance across industries, while dashboards highlight overdue items and areas needing corrective action.

How do facility managers leverage machine learning and real-time data to drive data-driven decisions in CBM?

Facility leaders apply machine learning to detect anomalies, predict failure risk, and prioritize maintenance actions. Combined with real-time condition monitoring and maintenance history, these insights optimize schedules, reduce inventory stockouts, improve equipment health, and inform capital planning for critical assets.

Can condition-based maintenance software integrate with existing enterprise asset management systems?

Yes. Modern platforms support secure, seamless integration with EAM, ERP, and inventory systems via APIs, webhooks, and connectors. This unifies asset records, work orders, parts, and costs while preserving accurate data flows and access controls.

What key performance indicators (KPIs) should maintenance managers track in a condition-based maintenance program?

Focus on MTBF, MTTR, asset availability, unplanned downtime, planned-vs-reactive ratio, schedule compliance, work order cycle time, first-time fix rate, parts stockouts, and maintenance costs per asset. Track risk scores and condition trends to validate CBM effectiveness and drive continuous improvement.

How does CMMS software support effective maintenance planning using maintenance history and asset performance data?

A CMMS consolidates maintenance history, condition trends, and failure modes to inform effective planning. Planners build standardized job plans, forecast labor and parts, level the schedule, and align PM/CBM tasks with production windows—improving timely completion and overall maintenance efficiency.

Get more done with MaintainX

.png)