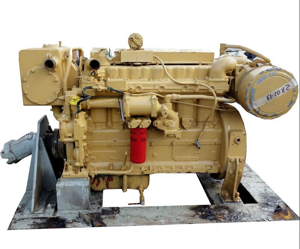

The CAT Bulldozer D6N is a robust and versatile piece of heavy machinery designed for various earthmoving tasks. Known for its durability and efficiency, this model excels in construction and mining applications, making it a reliable choice for operators seeking high performance and productivity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for CAT CAT Bulldozer D6N D6N

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

CAT CAT Bulldozer D6N D6N

Create an account to install this asset package.

Maintenance Plans for CAT CAT Bulldozer D6N Model D6N

Integrate maintenance plans directly into your work orders in MaintainX.

Hydraulic System Oil Level – Check

Warning: At operating temperature, the hydraulic tank is hot and under pressure. Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin. Remove the filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand. Remove the filler cap slowly in order to relieve pressure.

The hydraulic tank is on the right rear corner of the machine.

Is the counterweight fully retracted?

Enter the oil level in sight gauge (1)

Does the hydraulic system require additional hydraulic oil?

If the hydraulic system requires additional hydraulic oil, remove filler cap (2) and add oil. Clean filler cap (2) and install filler cap (2).

Sign off on the hydraulic system oil level check

10 Hourly or 1 Daily Bulldozer Maintenance

Controls for proper operation of boom and hook

Boom Stop operation

Warning: The Boom Stop system stops the boom winch from hauling-in when the boom is vertical, preventing overloading of key machine components. Incorrectly adjusting, or defeating the boom stop valve could result in serious equipment damage, personal injury, or even death. Its operation must be check and verified daily.

Boom Pivot Pins – Lubricate

Counterweight Cylinder Bearings – Lubricate

Counterweight Hinge Pins – Lubricate

Fairlead Sheave – Lubricate

Hook and Wire Cable (Boom and Hook lines) – Inspect

Hydraulic System Oil Level – Check

Hook Load Line – Install

Warning: Do not operate or work on this equipment unless you have read and understand the instructions and warnings in the Operation and Maintenance Manual. Failure to follow the instructions or heed the warnings could result in injury or death. Contact your dealer or Vanguard Equipment or visit our website at vanguardequip.com for replacement manuals. Proper care is your responsibility.

Warning: Personal injury or death can result from worn wire rope cable. Worn or frayed cable could break causing injury. Check the wire rope cable. If cable is worn or is frayed install new cable. Wear gloves when handling the wire rope cable. Proper care is your responsibility.

NOTICE: Make sure that the construction of the wire rope is 6x25 IWRC XIPS (Independent Wire Rope Core, eXtra Improved Plow Steel)conforming to ISO 2408. Also, the established grade of the wire rope is the improved plow bolt (steel), 26670 kg (58,800lb) minimum breaking strength.

Lower the boom to the horizontal position.

Remove the anchor for the wire rope from the drum for the hook. Remove the old wire rope.

Unroll the new wire rope from the spool.

Note: Weld the cable ends in order to prevent fraying.

NOTICE: Unroll all of the cable from the spool. Lay the wire rope on a flat surface. Never lift the wire rope off the spool in coils.

Install the cable into the small slot and through the larger slot in the drum for the boom.

Oil Filter Inspection

Warning: This procedure requires trained personnel with PPE!

Filter element cut open successfully?

Metal or other debris found in the filter element?

If metals are found, use a magnet to differentiate between ferrous and nonferrous metals.

Type of metal found

Ferrous metals indicate wear on steel parts and on cast iron parts. Nonferrous metals indicate wear of the brass or aluminum part of the hydraulics.

Small amounts of debris found?

Small amounts of debris may be caused by friction and normal wear.

Excessive amount of debris found?

Removal of the Boom

Lower the boom enough to remove the load blocks and the sheave block

Remove cotter pin, the retainer, and pin (1). Lower the load block and the hook block to the ground

Replace the pin (1) in the boom

Place the load block and the hook block in the front-mounted rigging tray, and secure the blocks to the tray for transportation

Draw in the excess hook cable in order to pull the sheave blocks to the machine. Use the Hook Line Stowing Guide to keep the line clear of the tracks. DO NOT over tighten the cables

Lower the boom to the horizontal position onto wood blocks that are sufficient to support the boom

Remove the cotter pin, the retainer, and pin (2)

Replace the pin and the retainer (2) in the boom

Move the luff block clear of the boom and area; it will be secured after the boom has been removed

Parts for CAT CAT Bulldozer D6N D6N

Access the parts list for your equipment in MaintainX.

Coupling

118-6539

Washer, Hard, Z (1/2)

8T-4223

Shaft, Pto

224-1144

O-Ring

8S-5654

Washer, Hard, Z (1/2)

5P-1076

Coupling

118-6539

Washer, Hard, Z (1/2)

8T-4223

Shaft, Pto

224-1144

O-Ring

8S-5654

Washer, Hard, Z (1/2)

5P-1076

Coupling

118-6539

Washer, Hard, Z (1/2)

8T-4223

Shaft, Pto

224-1144

O-Ring

8S-5654

Washer, Hard, Z (1/2)

5P-1076

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX