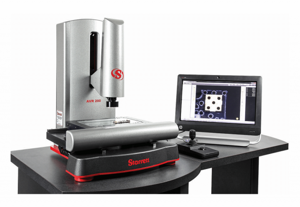

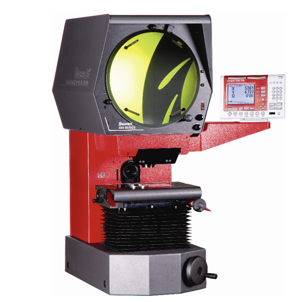

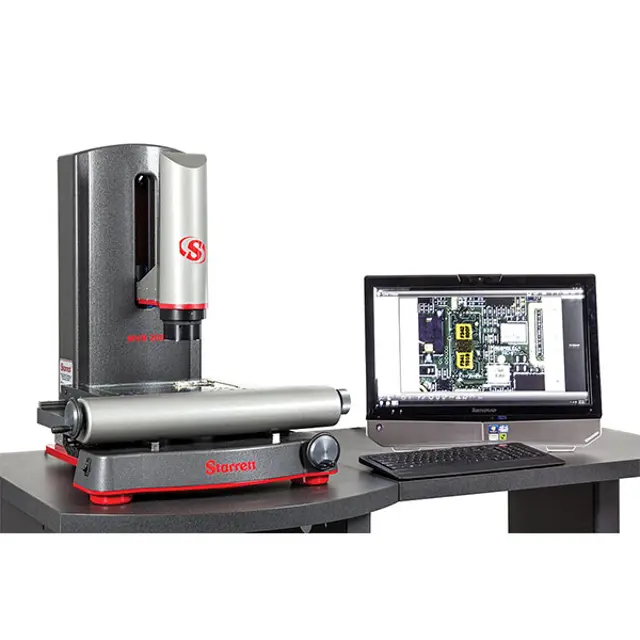

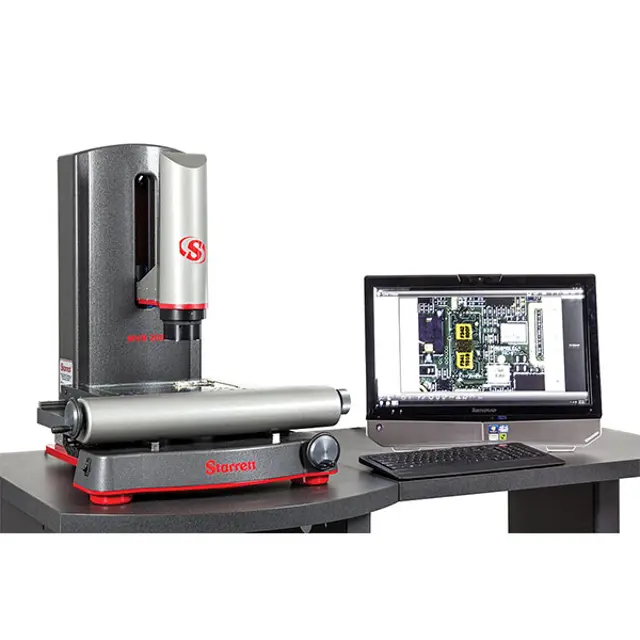

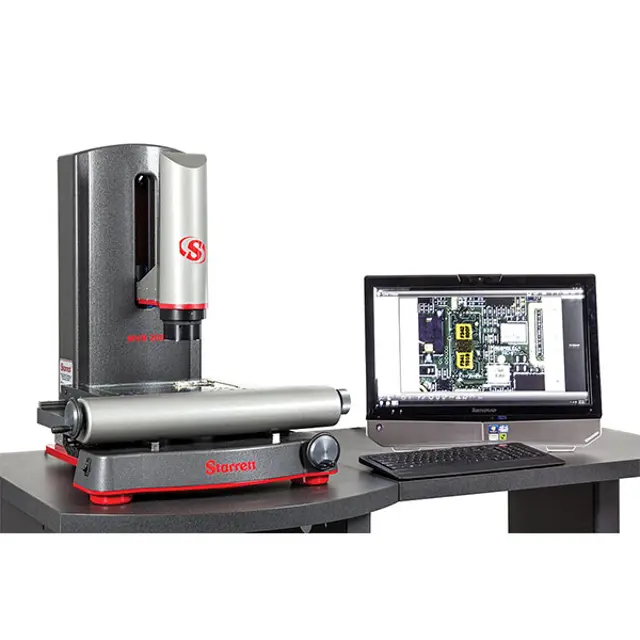

The Starrett Vision Metrology System AV450 is a precision optical measurement tool designed for high accuracy in industrial applications. This advanced system offers reliable performance and is essential for quality control and inspection processes in manufacturing environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Starrett Vision Metrology System AV450

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Starrett Vision Metrology System AV450

Create an account to install this asset package.

Maintenance Plans for Starrett Vision Metrology System Model AV450

Integrate maintenance plans directly into your work orders in MaintainX.

Parfocality Check

Warning: This procedure requires trained personnel!

Place the MAG checker or other suitable inspection part on the stage and secure properly.

Backlight the image as necessary. Set light levels as needed to avoid blooming.

At low magnification, select a flat, sharp edge in the center of the field of view (FOV).

Select highest magnification, and carefully refocus the image by physically moving the Z-axis up or down.

While observing the feature, slowly adjust the magnification lower. Verify that the feature remains focused as the magnification is lowered.

Report any observed discrepancy.

If the error is verified, contact your Starrett representative for authorized service.

Sign off on the parfocality check

Vision Metrology System Cleaning

• To the degree possible, the system should be kept in a clean environment, away from dirt, dust, oil and debris which could affect system performance or degrade the system’s mechanical and electronic parts. If a clean environment is not available, the machine should be kept as clean and protected as is possible.

• In harsh environments, preventive maintenance and factory service should be scheduled more frequently to keep the system in top working order.

WARNING: Never pour fluid on the system when cleaning. Do not over-wet cleaning cloth. Excessive moisture can seep into mechanical or electrical parts, damage the equipment and possibly cause an electrical short circuit and physical injury. As a precaution, unplug the system if needed before cleaning the system. Always unplug the system before using any flammable cleaning fluid.

1. Cleaning External Surfaces

• Wipe down with a clean, lint-free cloth moistened (not wet) with plain water or Simple Green®.

• Never wipe down with acetone or other harsh solvents, which may damage painted or plastic surfaces. Isopropyl alcohol may be used to clean surface contaminants where Simple Green proves ineffective.

2. Cleaning Optics

WARNING: Do not touch lens surfaces with your fingertips, since the resulting fingerprints will destroy optical coatings over time. Only clean optical surfaces with proper cleaning supplies, and then only when necessary.

• If a lens is covered with loose dust, first try blowing off this dust using a can of optical grade (oil-free) canned compressed air. Be careful not to shake the lens, or propellant may blow onto the lens. As alternative, use a lens brush to gently wipe off the dust.

Squareness Check

Squareness refers to the alignment of the camera relative to the motion of the metrology stage. If the camera is misaligned (out of square), an image will appear to drift diagonally across the video image as the stage position is moved along one axis.

Place the MAG checker or other suitable inspection part on the stage and secure properly.

Is the crosshair image tool at its defined center position?

At low mag, select a point-like feature such as a corner or the standard’s X-Y origin. Using the stage, position it to the center of the crosshair.

Zoom to high magnification, then refocus and recenter the point as needed.

While observing the feature, slowly move the stage X axis ONLY. (Do not move the stage Y axis.) Verify that the point remains aligned on the X axis of the crosshair as the feature is moved to the left and right within the field of view.

Does the point remain aligned on the X axis of the crosshair as the feature is moved to the left and right within the field of view?

Report any observed discrepancy.

If the error is verified, contact your Starrett representative for authorized service.

Bulb Replacement

NOTE: The lights of a fiber-optic metrology system generate heat. To preserve lamp life and reduce unnecessary heat buildup, turn the lights down when the system is not in use.

WARNING: Power the system down properly and unplug the unit from the power supply before opening the electronics enclosure.

CAUTION: The lamp bulbs are very hot and can cause burns if not allowed to cool properly.

Do not touch any part of the new bulb when inserting. The inner reflective surface of the lens and the filament housing are particularly susceptible to damage. Oils from fingers and hands can contaminate the surface and shorten the bulb life. Use a clean cloth or tissue, or wear clean latex gloves to handle the new bulb.

Do not to get any part of a tissue or cloth caught in the bulb contacts to avoid a potential fire hazard.

The bulb must be fully seated in the socket to prevent arcing and premature failure of the bulb and damage to the socket.

Verify which lamp needs to be replaced

Properly powered the system down and unplugged the unit from the power source?

Loosened the light bundle retaining screw and removed the light bundle from the heat sink?

6 Monthly Lead-Screw Lubrication

Warning: Use only approved lubricants, as inappropriate lubricants can damage system components.

Is the lubricant Tri-Flow®?

If the lubricant is not Tri-Flow®, stop the procedure and contact Starrett or an authorized Starrett representative.

Enter the amount of Tri-Flow® used

Did you traverse the stage or column through the entire range of travel several times to distribute the lubricant?

Did you use a clean soft cloth or paper towel to wipe up any excess?

Sign off on the lubrication process

Parts for Starrett Vision Metrology System AV450

Access the parts list for your equipment in MaintainX.

Stage Glass

5485

Stage Glass

5485

Stage Glass

5485

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX