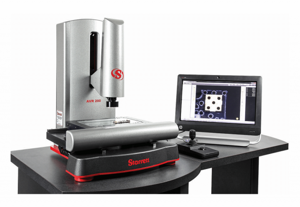

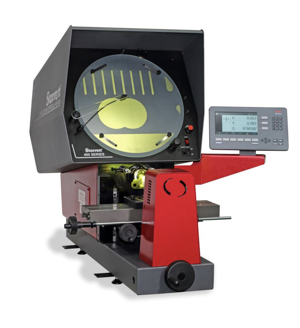

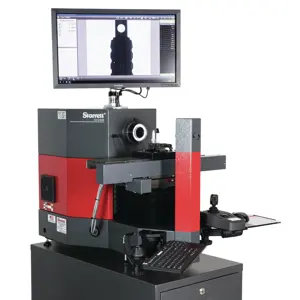

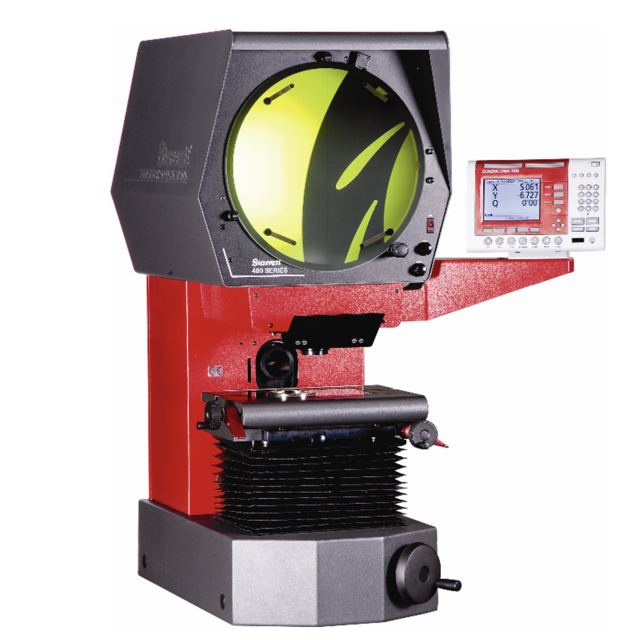

The Starrett Optical Projector VB400 is a precision measurement tool designed for high-quality optical inspection and measurement tasks. This reliable projector is ideal for various industrial applications, ensuring accurate results and enhanced productivity in manufacturing environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Starrett Optical Projector VB400

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Starrett Optical Projector VB400

Create an account to install this asset package.

Maintenance Plans for Starrett Optical Projector Model VB400

Integrate maintenance plans directly into your work orders in MaintainX.

Optical Projector Cleaning

1. Cleaning Lenses

CAUTION - Do not use polishes, or window cleaning aerosols and liquids for cleaning lenses.

• Do not touch the inner surfaces, (those facing away from the work piece), of the projection or condenser lens. The projection lens is the most critical; a finger mark on the inner surface will degrade the quality of the projected image.

• Remove any accumulated dust with a photographic lens brush.

• Remove any grease or finger marks with a new photographic cleaning tissue, which may be moistened with methanol if necessary.

2. Cleaning the Mirror

CAUTION - The mirror should be cleaned as infrequently as possible. It is recommended that cleaning is performed by service engineers.

• Do not place fingers on the surface of the mirror.

• If necessary, remove loose dust with a photographic lens brush.

Projection Lens Replacement

CAUTION - Do not touch the surfaces of the lens.

Upload a photo of the lens before removal

Rotate the lens anti-clockwise and withdraw it

Upload a photo of the lens after removal

Fit the replacement lens

Rotate the replacement lens clockwise until it is secure

Check that the two red spots are aligned

Upload a photo of the lens after replacement

Sign off on the lens replacement

Latch Block Adjustment

Warning: This procedure requires trained personnel with PPE!

End cap successfully withdrawn?

Engagement handle unscrewed and removed?

Allen key inserted into the socket lock screw and screw slackened?

Internal nut held in position with the key?

Bearing mount/collet rotated to give the required tension?

Socket lock screw tightened?

Engagement handle and end cap refitted?

Sign off on the latch block adjustment

60000 Hourly Profile Illumination Replacement

Warning: This procedure requires trained personnel with PPE!

LED lighting functional?

If LED lighting is not functional, contact Projector Dealer or SPO Technical Department.

LEDs passed environmental and mechanical stress tests?

LED's lifetime hours

LEDs help reduce power consumption and are free of hazardous materials.

Surface illumination functional?

If surface illumination is not functional, contact Projector Dealer or SPO Technical Department.

Sign off on the illumination replacement

Parts for Starrett Optical Projector VB400

Access the parts list for your equipment in MaintainX.

Profile High/Low Switch

5H07

X100 Lens Assembly

10E012

X50 Lens Assembly

10E011

Mirror

10D03

X25 Lens Assembly

10E008

Profile High/Low Switch

5H07

X100 Lens Assembly

10E012

X50 Lens Assembly

10E011

Mirror

10D03

X25 Lens Assembly

10E008

Profile High/Low Switch

5H07

X100 Lens Assembly

10E012

X50 Lens Assembly

10E011

Mirror

10D03

X25 Lens Assembly

10E008

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX