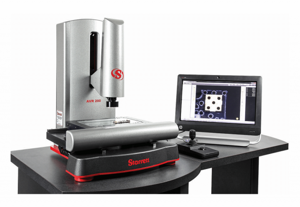

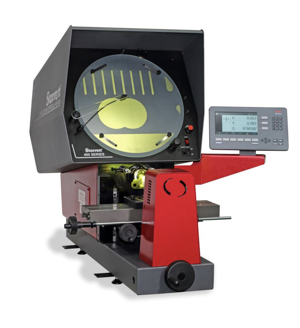

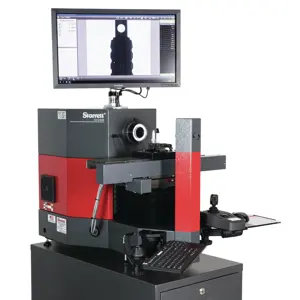

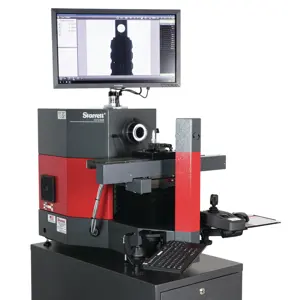

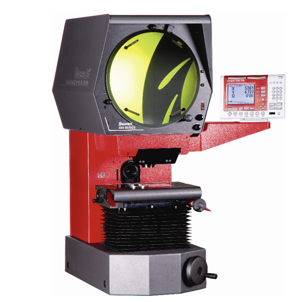

The Starrett Optical Projector HF600 is a precision measurement tool designed for accurate dimensional analysis in manufacturing and quality control. This versatile optical projector combines advanced optics with user-friendly features, making it essential for professionals seeking reliable performance in their inspection processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Starrett Optical Projector HF600

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Starrett Optical Projector HF600

Create an account to install this asset package.

Maintenance Plans for Starrett Optical Projector Model HF600

Integrate maintenance plans directly into your work orders in MaintainX.

Profile Illumination Lamp Replacement

CAUTION! Do not finger the surface of the new lamp; handle it in its protective wrapping. Any fingermarks will be fired into the surface of the quartz envelope, reducing the output and life of the lamp. If the envelope is accidentally finger marked, remove the marks immediately with a cotton wool swab moistened with methanol.

Removed the 3 securing screws from the profile lamp cover and lifted the cover clear

Removed the used lamp by holding it carefully between finger and thumb and pulling it gently upwards until the terminal pins are clear of the connectors (4)

Removed the new replacement lamp from its box and with a sharp knife cut approximately 6 mm (1/4 in) from the bottom of the protective wrapping, allowing the terminal pins to protrude

Holding the lamp by its protective wrapping, inserted the terminal pins into the connectors (4)

Checked that the lamp is vertical and securely located, and disposed of the protective wrapping

Refitted the lamp cover and secured it with the 3 screws

Sign off on the lamp replacement

Optical Projector Cleaning

1. Cleaning Lenses

CAUTION! Do not use polishes, or window cleaning aerosols and liquids for cleaning lenses. Do not touch the inner surfaces, (those facing away from the workpiece), of the projection or condenser lens. The projection lens is the most critical; a finger mark on the inner surface will degrade the quality of the projected image.

• Remove any accumulated dust with a photographic lens brush.

• Remove any grease or fingermarks with a new photographic cleaning tissue, which may be moistened with methanol if necessary.

2. Cleaning the Mirror

CAUTION! The mirror should be cleaned as infrequently as possible. It is recommended that cleaning is performed by an authorised service engineer. Do not finger the surface of the mirror.

• If necessary, remove loose dust with a photographic lens brush.

• If necessary, remove grease and finger marks with surgical quality cotton wool moistened with methanol. Apply the cotton wool lightly, and then polish the surface with clean dry surgical quality cotton wool.

CAUTION! Do not use force.

Latch Block Adjustment

Warning: This procedure requires trained personnel with PPE!

End cap successfully withdrawn?

Engagement handle successfully removed?

Allen key inserted into the socket lockscrew?

Socket lockscrew released and internal nut held in position?

Bearing mount/collet rotated to give the required tension?

Socket lock screw tightened?

Engagement handle and end cap refitted?

Sign off on the latch block adjustment

Projection Lens Replacement

CAUTION! Do not touch the surfaces of the lens.

Slacken the two screws securing the clamps (2)

Remove screws and clamps

Withdraw the lens

Fit the replacement lens

Secure the clamps and tighten the securing screws

Sign off on the lens replacement

Surface Illumination Lamp Replacement

Remove the two screws securing the cover

Remove the surface illumination lamp cover

Raise the wire handle of the lamp ejection clip on the housing to lift the lamp pins out of their connectors, and remove the used lamp

Insert the new lamp into the housing

Refit the lamp cover and secure it with the two screws

Sign off on the lamp replacement

Parts for Starrett Optical Projector HF600

Access the parts list for your equipment in MaintainX.

Cooling Fan Hot Lamp Set 80mm

HL101

Profile Illumination And Hot Lamp Lamp Holder

LH11

Fuse 6.3A

9J03

Cooling Fan Profile 120mm

LH26

Linear Transducer Scale, X-axis 320mm

VPP320

Cooling Fan Hot Lamp Set 80mm

HL101

Profile Illumination And Hot Lamp Lamp Holder

LH11

Fuse 6.3A

9J03

Cooling Fan Profile 120mm

LH26

Linear Transducer Scale, X-axis 320mm

VPP320

Cooling Fan Hot Lamp Set 80mm

HL101

Profile Illumination And Hot Lamp Lamp Holder

LH11

Fuse 6.3A

9J03

Cooling Fan Profile 120mm

LH26

Linear Transducer Scale, X-axis 320mm

VPP320

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX