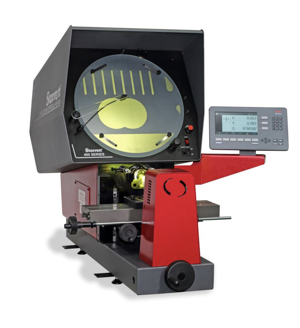

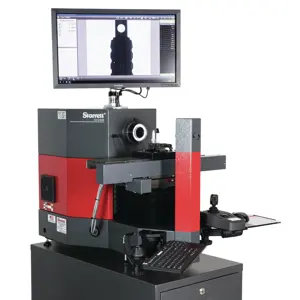

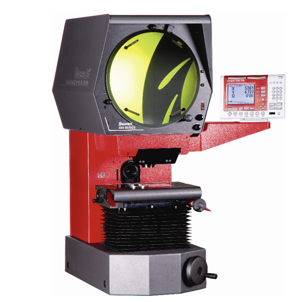

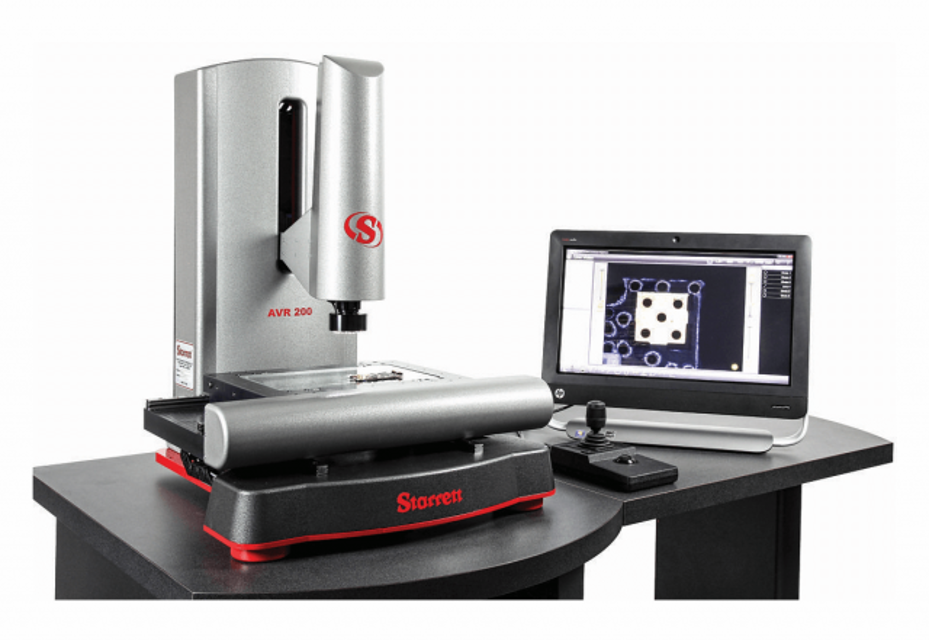

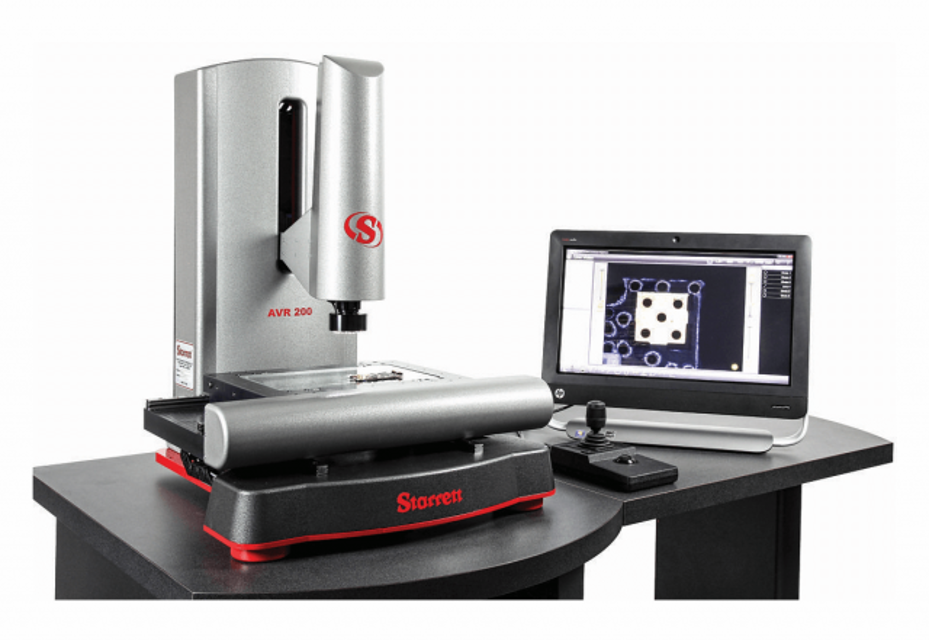

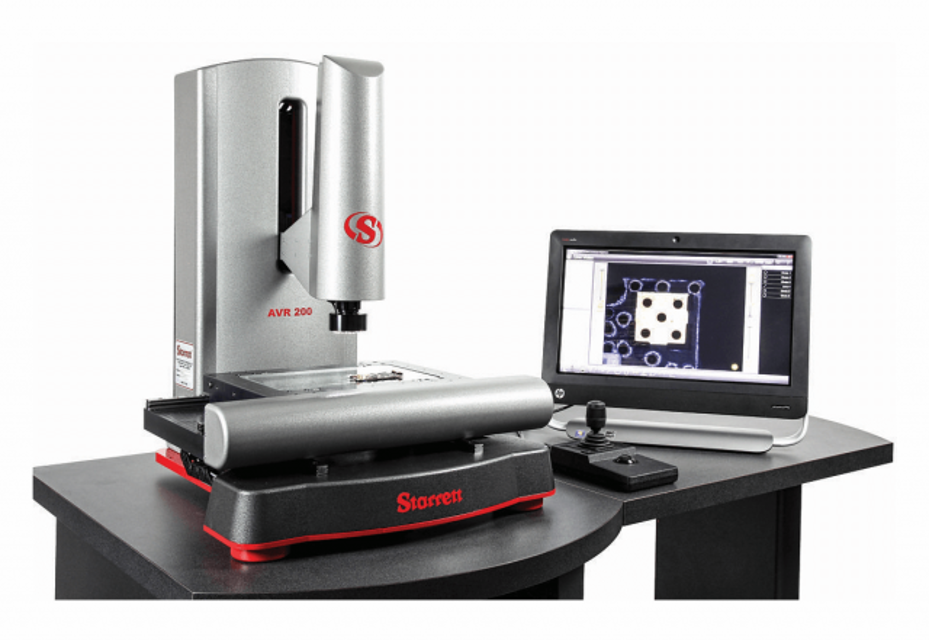

The Starrett Automatic Video Metrology System AVR200 is a cutting-edge measurement solution designed for precision and efficiency in industrial applications. This advanced system offers automated video measurement capabilities, ensuring accurate results and streamlined workflows for quality control processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Starrett Automatic Video Metrology System AVR200

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Starrett Automatic Video Metrology System AVR200

Create an account to install this asset package.

Maintenance Plans for Starrett Automatic Video Metrology System Model AVR200

Integrate maintenance plans directly into your work orders in MaintainX.

1 Monthly Calibration Verification

• While not always strictly necessary, it is recommended that the calibration verification described in this section be performed periodically depending on user experience.

• A linear calibration verification standard (200mm linear standard) artifact is available from Starrett authorized distributors or directly from the Starrett service department. Refer to “Spare Parts and Accessories” later in this section for additional information.

• Calibration should also be verified after the system has been serviced or moved. The following is a brief description of the steps recommended for the verification of your machine.

To validate calibration, perform the following steps:

1. Place the calibrated verification standard in one the six positions on the glass stage as shown in the previous figure. Secure the standard with hot melt glue or other suitable retaining method so that stage translation cannot move the standard under any condition.

2. Skew the center of the two end circles. Refer to the MetLogix M3 Video and FOV Inspection Software User’s Guide for detailed information.

3. Measure the distance between the 1st and 2nd, 1st and 3rd, 1st and 4th, 1st and 5th, and the 1st and 6th fiducials.

4. Repeat these measurements three times.

5. Calculate the absolute average deviation for each of the six groups of distance measurements.

1 Weekly Automatic Video Metrology System Inspection

Stage control mechanisms move freely

If binding is observed, contact SKE Technical Services for service. Do not apply cleaner or lubricant.

Basic calibration check against a certified chrome-on-glass standard

Refer to “Spare Parts and Accessories” for part number 8268.

Single measurement on an artifact with telecentric system

Measure artifacts at the zoom detent positions for maximum magnification with a zoom system

Measure artifacts at the zoom detent positions for minimum magnification with a zoom system

1 Monthly Zoom Optics Parcentricity Check

Parcentricity Check Procedure

MAG checker or other suitable inspection part properly secured on the stage

Crosshair image tool at its defined center position

Crosshair centered on the X-Y axis of the calibration standard at low magnification

Image refocused at high magnification

Crosshair recentered on the feature at high magnification

Feature remains at the center of the crosshair as the magnification is lowered

Report any observed discrepancy

If the error is verified, contact your Starrett representative for authorized service

1 Monthly Zoom Optics Parfocality and Focus Check

Parfocality is the condition in which the video image remains in focus as the magnification is adjusted from highest to lowest. Starrett zoom optics are designed to maintain parfocality throughout their magnification range.

To check parfocality, always reference a flat, sharp edge. Do not select a rough or sloping feature. The magnification (Mag) checker provided with the system is an ideal part to check parfocality.

Place the MAG checker or other suitable inspection part on the stage and secure properly.

Backlight the image as necessary. Set light levels as needed to avoid blooming.

At low magnification, select a flat, sharp edge in the center of the field of view (FOV).

Select highest magnification, and carefully refocus the image by physically changing the viewing distance.

While observing the feature, slowly adjust the magnification lower. Verify that the feature remains focused as the magnification is lowered.

Report any observed discrepancy.

If the error is verified, contact your Starrett representative for authorized service.

1 Monthly Zoom Optics Squareness Check

Squareness refers to the alignment of the camera relative to the motion of the metrology stage. If the camera is misaligned (out of square), the image will drift diagonally across the screen as the stage is moved along the other axis.

Place the magnification (Mag) checker or other suitable inspection part on the stage and secure properly.

Select the crosshair image tool in software and verify that it is at its defined center position. Refer to the MetLogix M3 Video and FOV Inspection Software User’s Guide for detailed information.

At low magnification, select a point-like feature such as a corner or the standard’s X-Y origin. Using the stage, position it to the center of the crosshair.

Zoom to high magnification, then refocus and recenter the point as needed.

While observing the feature, slowly move the stage X axis only. (Do not move the stage Y axis.) Verify that the point remains aligned on the X axis of the crosshair as the feature is moved to the left and right within the field of view.

Report any observed discrepancy. If the error is verified, contact your Starrett representative for authorized service.

Sign off on the squareness check

Parts for Starrett Automatic Video Metrology System AVR200

Access the parts list for your equipment in MaintainX.

200mm Line Standard

8736-1

4 X 7 Inch Calibration Standard

8440-1

AVR200 Stage Glass

4865-1

Field Of View Calibration Grid

5736-1

Magnification (MAG) Checker

8268

200mm Line Standard

8736-1

4 X 7 Inch Calibration Standard

8440-1

AVR200 Stage Glass

4865-1

Field Of View Calibration Grid

5736-1

Magnification (MAG) Checker

8268

200mm Line Standard

8736-1

4 X 7 Inch Calibration Standard

8440-1

AVR200 Stage Glass

4865-1

Field Of View Calibration Grid

5736-1

Magnification (MAG) Checker

8268

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX