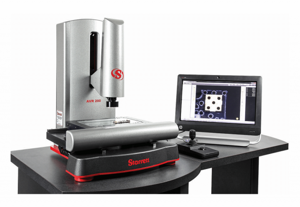

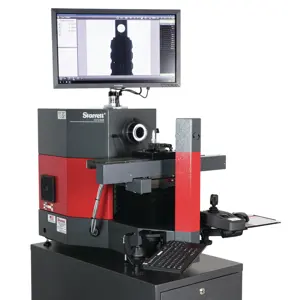

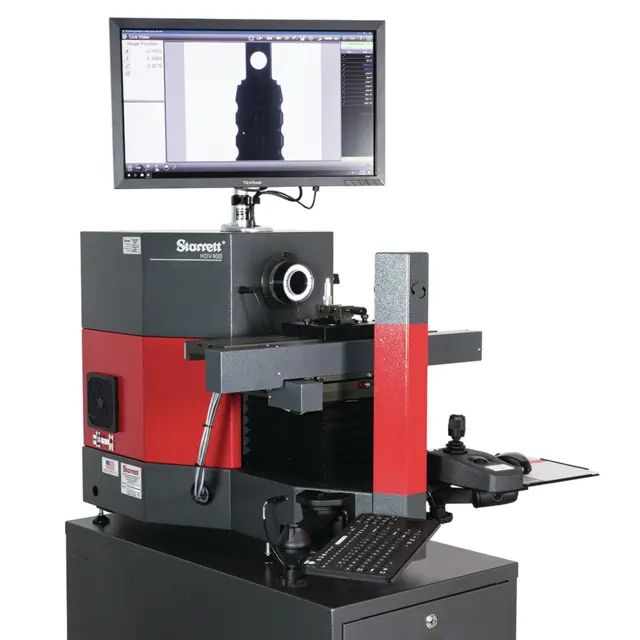

The Starrett Horizontal Digital Video System HDV300 is a high-performance asset designed for precision measurement and inspection. This advanced video system offers exceptional image quality and reliability, making it ideal for industrial applications. Ensure optimal performance with regular maintenance and quality spare parts.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Starrett Horizontal Digital Video System HDV300

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Starrett Horizontal Digital Video System HDV300

Create an account to install this asset package.

Maintenance Plans for Starrett Horizontal Digital Video System Model HDV300

Integrate maintenance plans directly into your work orders in MaintainX.

Automatic Video Metrology System Cleaning

• To the degree possible, the system should be kept in a clean environment, away from dirt, dust, oil, and debris which could affect system performance or degrade the system’s mechanical and electronic parts. If a clean environment is not available, the machine should be kept as clean and protected as is possible. In harsh environments, preventive maintenance and factory service should be scheduled more frequently to keep the system in top working order.

WARNING! Never pour fluid on the system when cleaning. Do not over-wet cleaning cloth. Excessive moisture can seep into mechanical or electrical parts, damage the equipment and possibly cause an electrical short circuit and physical injury. As a precaution, unplug the system before cleaning. Always unplug the system before using any flammable cleaning fluid.

1. Cleaning External Surfaces

• Wipe down with a clean, lint-free cloth moistened (not wet) with plain water, ammonia-free glass cleaner, or isopropyl alcohol. Never wipe down with acetone or other harsh solvents, which can damage painted or plastic surfaces.

2. Cleaning Optics

CAUTION! Do not touch lens surfaces with your fingertips. Fingerprints can destroy optical coatings over time. Only clean optical surfaces with proper cleaning supplies, and then only when necessary.

To clean the lens, refer to the following guidelines:

• If a lens is covered with loose dust, do the following:

1. Use a can of optical grade (oil-free) canned compressed air to blow off the dust. Be careful not to shake the lens, or propellant can blow onto the lens.

Fuse Replacement

WARNING! Always unplug the 115V or 230V power cable before starting work.

Power properly applied to the system but electronics not operating?

If yes, the problem could be due to a blown fuse.

Unplug the power cable from the rear power switch.

Pry open the cover above the power switch.

Pry out the red fuse holder module.

Check the existing fuses for electrical continuity.

Replace any blown fuse with a fresh fuse of the same size.

The recommended fuse rating is 5A, 250 Vac for 115V or 230V AC power.

6 Monthly Lead Screws Lubricating

Warning: Use only approved lubricants, as inappropriate lubricants can damage system components.

Approved lubricant obtained?

Lubricant applied to each screw?

Stage or column traversed through the entire range of travel several times to distribute the lubricant?

Excess lubricant wiped up with a clean soft cloth or paper towel?

Sign off on the lubrication process

1 Monthly Calibration Verification

Calibration should be verified periodically depending on user requirements, system usage, and should be performed at least monthly.

Calibration should also be verified after the system has been serviced or moved.

A chrome-on-glass calibration verification standard artifact is available from Starrett or its authorized distributors.

This standard has a length of 300 millimeters and major calibration fiducials spaced every 25 millimeters.

To validate calibration, perform the following steps:

Place the calibrated standard along the X-axis. Secure the standard to the stage with a holder (available from Starrett).

Skew the center of the two end circles of the calibration standard. Refer to the M3 Software User Guide for proper alignment procedure.

Using the HDV system, measure the position of fiducials spaced every 25 millimeters. For each fiducial, take the average of multiple readings for improved accuracy.

Calculate the absolute measurement error for each fiducial by subtracting the calibrated position of the fiducial from the above average readings.

1 Monthly Zoom Optics Parfocality and Focus Check

Parfocality is the condition in which the video image remains in focus as the magnification is adjusted from highest to lowest. Starrett zoom optics are designed to maintain parfocality throughout their magnification range. To check parfocality, always reference a flat, sharp edge. Do not select a rough or sloping feature. The magnification (Mag) checker provided with the system is an ideal part to check parfocality.

MAG checker or other suitable inspection part is placed on the stage and secured properly.

Backlight the image as necessary. Set light levels as needed to avoid blooming.

At low magnification, a flat, sharp edge in the center of the field of view (FOV) is selected.

At highest magnification, the image is refocused by physically changing the viewing distance.

While observing the feature, the magnification is slowly adjusted lower. The feature remains focused as the magnification is lowered.

Report any observed discrepancy.

If the error is verified, contact your Starrett representative for authorized service.

Sign off on the parfocality and focus check

Parts for Starrett Horizontal Digital Video System HDV300

Access the parts list for your equipment in MaintainX.

Cabinet Stand 22-Inch High

8171

Cabinet Stand 31-Inch High

8170

Time Delay Fuse 6A, 250 VAC, 6.3 × 32 mm (.25 × 1.26 inch)

5595

Combination FOV And Magnification Checker Calibration Standard

9123

400 Mm Line Standard

5584-1

Cabinet Stand 22-Inch High

8171

Cabinet Stand 31-Inch High

8170

Time Delay Fuse 6A, 250 VAC, 6.3 × 32 mm (.25 × 1.26 inch)

5595

Combination FOV And Magnification Checker Calibration Standard

9123

400 Mm Line Standard

5584-1

Cabinet Stand 22-Inch High

8171

Cabinet Stand 31-Inch High

8170

Time Delay Fuse 6A, 250 VAC, 6.3 × 32 mm (.25 × 1.26 inch)

5595

Combination FOV And Magnification Checker Calibration Standard

9123

400 Mm Line Standard

5584-1

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX