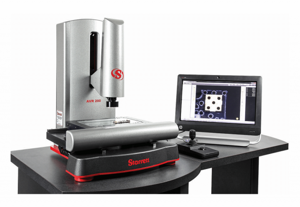

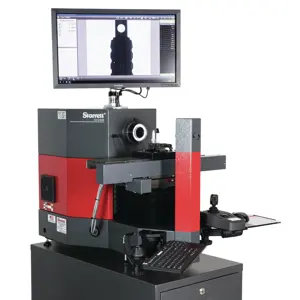

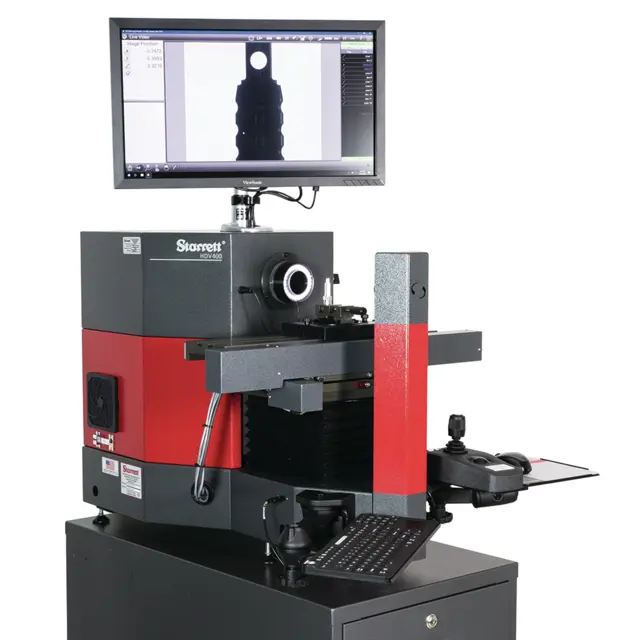

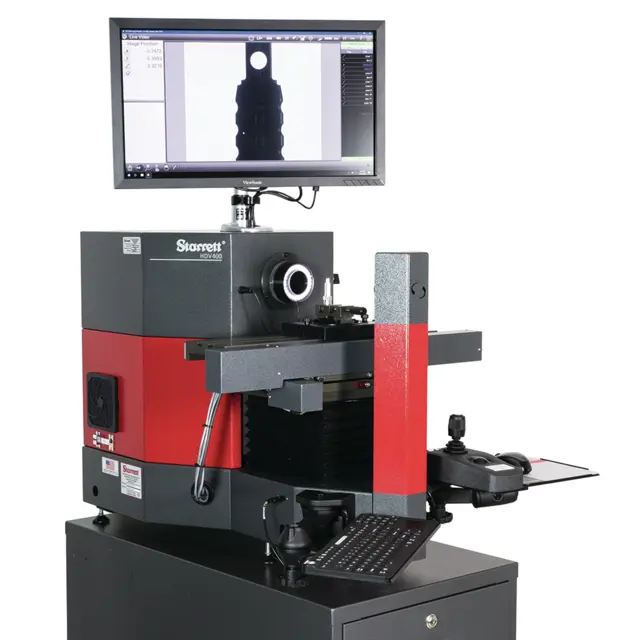

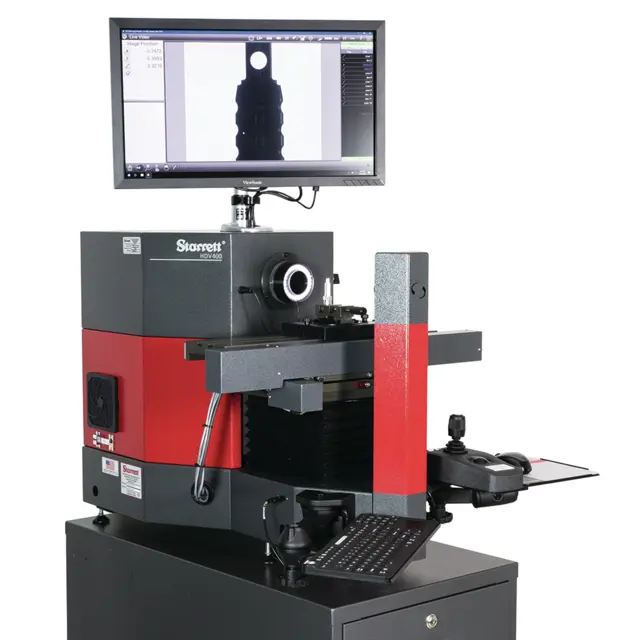

The Starrett Horizontal Digital Video System HDV400 is a high-precision measurement tool designed for industrial applications. This advanced system integrates digital video technology to enhance accuracy and efficiency in measurement tasks, making it an essential asset for quality control and inspection processes.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Starrett Horizontal Digital Video System HDV400

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Starrett Horizontal Digital Video System HDV400

Create an account to install this asset package.

Maintenance Plans for Starrett Horizontal Digital Video System Model HDV400

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Lead Screws Lubricating

Warning: Use only approved lubricants, as inappropriate lubricants can damage system components.

Enter the part number of the lubricant used

Lubricant applied to each screw?

Stage or column traversed through the entire range of travel several times to distribute the lubricant?

Excess lubricant wiped up with a clean soft cloth or paper towel?

Sign off on the lubrication process

1 Monthly Fan Filter Maintenance

• In a standard HDV configuration, the side of the housing includes a 4.7 inch (120 mm) fan that draws in ambient air through a filter and maintains a slightly positive pressure inside the housing. While the system is running, the air that comes in contact with the electronics has passed through this filter.

• Inspect the fan filter for cleanliness at least monthly. Fan filters and the fan itself are userreplaceable items. The filters and fan are available from electronics distributors and in computer stores. When purchasing a new fan, ensure that the voltage is 24V, as marked on the previous fan.

• To inspect the fan filter, refer to the following figure and perform the following steps:

1. Pry off the fan bezel with a flat-blade screwdriver and remove the filter, which is held by the bezel.

2. Inspect the fan filter. If the filter is dirty, it can be washed in hot water or be replaced.

3. To reinstall the filter, reseat it in the bezel and press the bezel back in place.;

Maintaining the System with an Inline Clean Air Kit

CAUTION! Do not rely on the supplied filter as the sole means of cleaning the air for the machine.

With the Inline Clean Air Kit, the fan on the side of the HDV is replaced with a panel and fittings to allow the use of pressurized air to keep the inside of the machine clean.

Pressure between 8 and 15 psi has been found to be effective at sufficiently pressurizing the housing to prevent the ingress of dust, particulates, oil vapors, and similar such as found in machine shop environments.

Air entering the machine must be clean and dry. It is recommended that air coming from the compressor be passed through a filter and dryer. The filter/moisture collector provided with the kit is designed as a failsafe to prevent damage to the machine should the method to filter and clean the air from the compressor fail.

Regularly check the openings of the machine to ensure that the housing is pressurized. If air is not felt escaping from openings, increase the pressure going to the machine.

Though testing has shown between 8 and 15 psi sufficiently pressurized the housing, differences in equipment and conditions might require more than 15 psi to pressurize the housing to an adequate level.

Note: Excessive air pressure is not necessary.

Periodically check the filter for contaminants and appearance of filter element.

If moisture is present, drain the filter by removing the black plug at the bottom of the inline filter as shown in the following figure.

1 Monthly Zoom Optics Parcentricity Check

Parcentricity describes the condition where a feature remains at the optical center of the video image throughout the magnification range. Like parfocality, parcentricity requires that the feature be first located at highest magnification.

Place the MAG checker or other suitable inspection part on the stage and secure properly.

Is the crosshair image tool at its defined center position?

Zoom to low magnification and adjust the stage position so that the crosshair is centered on the X-Y axis of the calibration standard (or another suitable feature if the standard is not used).

Change to high magnification and refocus the image.

Adjust the stage position as needed to recenter the crosshair on the feature.

Does the feature remain at the center of the crosshair as the magnification is lowered?

Report any observed discrepancy.

If the error is verified, contact your Starrett representative for authorized service.

1 Daily Horizontal Digital Video System Inspection

Verify that the work area is clean, dry and free of debris

Verify that the electrical power cord is plugged into a grounded power source and is unobstructed

Verify that temperature is within recommended range

Verify that humidity is within recommended range

Allow the system to warm up to normal operating temperature before performing critical parts measurements

Sign off on the daily inspection

Parts for Starrett Horizontal Digital Video System HDV400

Access the parts list for your equipment in MaintainX.

Lead Screw Lubricant

7946

Magnification Checker

8268

Light Shield

5781

Time Delay Fuse 6A, 250 VAC, 6.3 × 32 mm (.25 × 1.26 inch)

5595

Calibration Standard Fixture

7430

Lead Screw Lubricant

7946

Magnification Checker

8268

Light Shield

5781

Time Delay Fuse 6A, 250 VAC, 6.3 × 32 mm (.25 × 1.26 inch)

5595

Calibration Standard Fixture

7430

Lead Screw Lubricant

7946

Magnification Checker

8268

Light Shield

5781

Time Delay Fuse 6A, 250 VAC, 6.3 × 32 mm (.25 × 1.26 inch)

5595

Calibration Standard Fixture

7430

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX