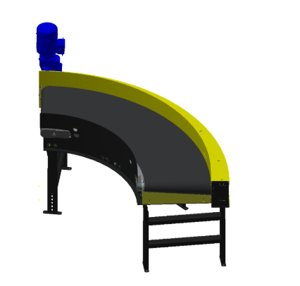

The Hytrol Minimum Pressure Live Roller Conveyor 190-ACZ is a robust and efficient conveyor system designed for material handling in industrial environments. This model ensures smooth operation and minimal pressure on products, making it ideal for various applications in manufacturing and distribution.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol Minimum Pressure Live Roller Conveyor 190-ACZ

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol Minimum Pressure Live Roller Conveyor 190-ACZ

Create an account to install this asset package.

Maintenance Plans for Hytrol Minimum Pressure Live Roller Conveyor Model 190-ACZ

Integrate maintenance plans directly into your work orders in MaintainX.

Racked Sections Check

It is important that each bed section be checked for an out-of-square condition. If conveyor is not square, tracking prob- lems will result. Figure 17A indicates a racked section.

TO CORRECT AN OUT-OF-SQUARE SECTION

1. Locate points on corners of section and measure distance “A” & “B”. If the dimensions are not equal, the section will need to be squared. (Figure 17B).

2. Use crossbracing supplied on underside of conveyor to square each section. Adjust turnbuckle until Dimensions “A” & “B” are equal.

3. After all bed sections have been checked and corrected for “racked condition”, tighten all butt couplings and pivot plate bolts.

4. Make final check to see that all conveyor sections are level across width and length. If entire conveyor is level, supports can be lagged to floor.

IMPORTANT: Being out of level width of conveyor can cause package drift on long conveyor lines.;

2080 Hourly / 6 Monthy Minimum Pressure Live Roller Conveyor Lubrication

Warning: This procedure requires trained personnel with PPE!

Is the drive chain pre-lubricated from the manufacturer?

If not, apply a good grade of non-detergent petroleum or synthetic lubricant (i.e., Mobile 1 Synthetic)

Enter the hours of operation since last lubrication

Enter the date of last lubrication

Select the operating environment

For harsh conditions, it is best to lubricate more frequently and develop a custom lubrication schedule

Enter any notes or observations about the drive chain condition

Sign off on the drive chain lubrication

Pressure Adjustment

MODEL 190-LR (Figure 27A)

Loosen bolts in Pressure Adjustment Angles

Raise Pressure Adjustment Angles until proper force is obtained

Retighten bolts

MODEL 190-ACZ (Figure 27B)

With conveyor running, reduce pressure on all tread rollers to zero by loosening the knurled adjustment nuts

Place heaviest item to be conveyed on infeed end of conveyor. Increase pressure under the item by tightening the knurled nuts

As the item moves, continue adjustment ahead of item until it moves the entire length of conveyor

Return item to infeed end of unit. It should now travel the entire length of conveyor. If not, repeat the adjustment procedure in the problem area

Belt Tracking Check

IMPORTANT: The drive belt should be checked for proper tracking prior to installing tread rollers. This will allow easy access to items that might need adjusting.

All bed sections are square

Conveyor is level across the width and length of unit

All pulleys, return idlers, and snub idlers are square with conveyor bed

Belt has been properly threaded through conveyor

IMPORTANT: When belt tracking adjustments are made, they should be minor (1/16 in. at a time on idlers, etc., should be sufficient.)

Give the belt adequate time to react to the adjustments. It may take several complete revolutions around the conveyor for the belt to begin tracking properly on long, slow conveyor lines.

Belt is traveling in the correct direction

Belt tracking problem

1 Weekly Minimum Pressure Live Roller Conveyor Check

MOTOR:

Check Temperature

DRIVE CHAIN

Lubricate

BELT

Check Lacing;

Parts for Hytrol Minimum Pressure Live Roller Conveyor 190-ACZ

Access the parts list for your equipment in MaintainX.

Bed Spacer (Specify BR)

B-03916

Frame Channel 5 ft. Long

B-05731

Frame Channel 6 ft. Long

B-05732

7/16 in. Hex Idler Bracket

B-00944

Hex Jam Nut-Heavy-3/8-16

041.300

Bed Spacer (Specify BR)

B-03916

Frame Channel 5 ft. Long

B-05731

Frame Channel 6 ft. Long

B-05732

7/16 in. Hex Idler Bracket

B-00944

Hex Jam Nut-Heavy-3/8-16

041.300

Bed Spacer (Specify BR)

B-03916

Frame Channel 5 ft. Long

B-05731

Frame Channel 6 ft. Long

B-05732

7/16 in. Hex Idler Bracket

B-00944

Hex Jam Nut-Heavy-3/8-16

041.300

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX