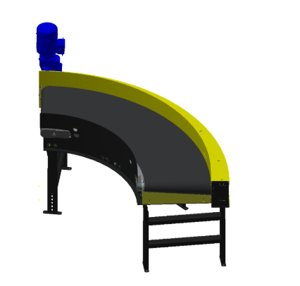

The Hytrol Belt Conveyor Gapper is an essential industrial asset designed for efficient material handling. This conveyor system optimizes product spacing and alignment, ensuring smooth operations in various manufacturing environments. Regular maintenance and timely spare parts replacement are crucial for maximizing performance and longevity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol Belt Conveyor Gapper

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol Belt Conveyor Gapper

Create an account to install this asset package.

Maintenance Plans for Hytrol Belt Conveyor Model Gapper

Integrate maintenance plans directly into your work orders in MaintainX.

1 Monthly Belt Conveyor Maintenance

MOTOR: Check Noise

Check Mounting Bolts

REDUCER: Check Noise

Check Temperature

BELT:

Check Tracking

Check Tension

BEARINGS (Pulleys & Rollers):

Check Noise

3 Monthly Belt Conveyor Maintenance

REDUCER:

Check Oil Level

DRIVE CHAIN:

Check Tension

Check for Wear

SPROCKETS:

Check for Wear

Check Set Screws & Keys

BEARINGS (Pulleys & Rollers):

1 Weekly Belt Conveyor Maintenance

Motor temperature within acceptable range?

Drive chain lubricated?

Belt lacing checked?

Belt Conveyor Lubrication

Warning: This procedure requires trained personnel with PPE!

Is the drive chain pre-lubricated from the manufacturer?

If not, report the issue to the maintenance team and stop the procedure

Choose the type of lubricant used

Enter the hours of operation since last lubrication

Is the chain sufficiently lubricated?

Describe the operating conditions

Sign off on the belt conveyor lubrication

Drive Chain Alignment and Tension

CAUTION!: Never remove chain guards while the conveyor is running. Always replace guards after adjustments are made

Remove chain guard

Check sprocket alignment by placing a straightedge across the face of both sprockets

Loosen set screws and adjust as needed

Re-tighten set screws

Loosen bolts that fasten motor base to mounting angles, both sides of the conveyor

Tighten take-up bolts until desired chain tension is reached

Re-tighten mounting bolts

Lubricate chain per lubrication instructions

Parts for Hytrol Belt Conveyor Gapper

Access the parts list for your equipment in MaintainX.

Floor Support Frame g" High (Specify OAW)

B-00915

Floor Support Frame 14 1/2" High (Specily OAW)

B-00917

Pulley Mount (Infeed)

B-23578

Floor Support Frame 22 1/2" High (Specily OAW)

B-00919

Floor Support Frame 90 1/2" High (Specily OAW)

B-02111

Floor Support Frame g" High (Specify OAW)

B-00915

Floor Support Frame 14 1/2" High (Specily OAW)

B-00917

Pulley Mount (Infeed)

B-23578

Floor Support Frame 22 1/2" High (Specily OAW)

B-00919

Floor Support Frame 90 1/2" High (Specily OAW)

B-02111

Floor Support Frame g" High (Specify OAW)

B-00915

Floor Support Frame 14 1/2" High (Specily OAW)

B-00917

Pulley Mount (Infeed)

B-23578

Floor Support Frame 22 1/2" High (Specily OAW)

B-00919

Floor Support Frame 90 1/2" High (Specily OAW)

B-02111

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX