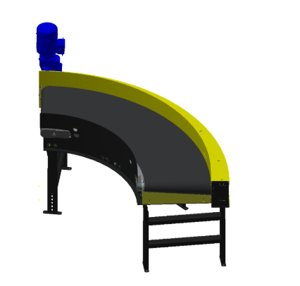

The Hytrol Belt Conveyor GAPPER-D is a robust industrial conveyor system designed for efficient material handling. Known for its reliability and versatility, this model excels in gap creation and product separation, making it ideal for various manufacturing and distribution applications. Optimize your operations with the Hytrol GAPPER-D conveyor.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol Belt Conveyor GAPPER-D

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol Belt Conveyor GAPPER-D

Create an account to install this asset package.

Maintenance Plans for Hytrol Belt Conveyor Model GAPPER-D

Integrate maintenance plans directly into your work orders in MaintainX.

3 Monthly Belt Conveyor Check

Reducer

Check Oi Level

Bearings (Pulleys & Rollers)

Check Mounting Bolts

Drive Chain

Check Tersion

Check for Wear

Sprockets

Check for Wear

2080 Hourly / 6 Monthy Belt Conveyor Lubrication

Warning: This procedure requires trained personnel with PPE!

Drive Chain lubrication serves several purposes including: Protecting against wear of the pin-bushing joint, Lubricating chain-sprocket contact surfaces, Preventing rust or corrosion

Enter the hours of operation since last lubrication

Enter the date of last lubrication

Is the drive chain sufficiently lubricated?

If not, lubricate with a good grade of non-detergent petroleum or synthetic lubricant (i.e., Mobile 1 Synthetic).

For best results, always use a brush to generously lubricate the chain.

Select the operating conditions

For harsh conditions, it is best to lubricate more frequently. Develop a custom lubrication schedule for your specific application.

1 Monthly Belt Conveyor Check

Motor:

Check Noise

Check Mounting Bolts

Reducer:

Check Noise

Check Temperature

Belt

Check Tracking

Check Tersion

Belt Replacement

Loosen belt by loosening the take-up bolt weldment on the spring take-up until belt is no longer in tension.

Remove tail pulleys, drive pulley and slider pan.

Upload a photo of the new belt installed as shown in Figure 6A.

Slide belt over tail pulleys. Belt is installed on top of Auto Belt Tracker and over Take-up pulley.

Put slider pan in place.

Reinstall drive pulley being careful belt is in proper position.

Tighten hardware.

Adjust belt tension by adjusting the take-up bolt weldment on the spring take-up. See Belt Tension section.

Sign off on the belt replacement

Drive Chain Alignment and Tension Check

Warning: This procedure requires trained personnel with PPE!

Chain guard removed

Sprocket alignment checked

Set screws loosened and adjusted

Motor base bolts loosened

Enter the desired chain tension

Mounting bolts re-tightened

Chain lubricated

Chain guard replaced without interfering with drive

Parts for Hytrol Belt Conveyor GAPPER-D

Access the parts list for your equipment in MaintainX.

Pulley Plate

PT-180019

1/2-13 X 1-1/2" LG Hex Head Cap Screw, Zine Plated

040.402

Take-Up Bracket

PT-167069

2-1/4" DIA Pulley Assembly - (Specify BR)

SA-081776-(BR)

Slider Pan - 55" LG (Specify BR)

PT-173415-(BR)

Pulley Plate

PT-180019

1/2-13 X 1-1/2" LG Hex Head Cap Screw, Zine Plated

040.402

Take-Up Bracket

PT-167069

2-1/4" DIA Pulley Assembly - (Specify BR)

SA-081776-(BR)

Slider Pan - 55" LG (Specify BR)

PT-173415-(BR)

Pulley Plate

PT-180019

1/2-13 X 1-1/2" LG Hex Head Cap Screw, Zine Plated

040.402

Take-Up Bracket

PT-167069

2-1/4" DIA Pulley Assembly - (Specify BR)

SA-081776-(BR)

Slider Pan - 55" LG (Specify BR)

PT-173415-(BR)

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX