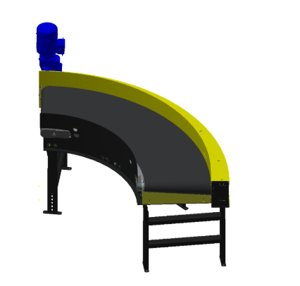

The Hytrol Belt Conveyor SBI is a robust and efficient material handling solution designed for various industrial applications. Known for its reliability and ease of maintenance, this conveyor system enhances productivity while minimizing downtime. Ideal for transporting goods in manufacturing and distribution environments, it ensures smooth operations with minimal interruptions.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol Belt Conveyor SBI

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol Belt Conveyor SBI

Create an account to install this asset package.

Maintenance Plans for Hytrol Belt Conveyor Model SBI

Integrate maintenance plans directly into your work orders in MaintainX.

Drive Chain Alignment and Tension Check

Warning: This procedure requires trained personnel with PPE!

Chain guard removed

Sprocket alignment checked

Set screws re-tightened

Chain tension adjusted

Mounting bolts re-tightened

Chain lubricated

Chain guard replaced

Sign off on the drive chain alignment and tension check

2080 Hourly / 6 Monthly Drive Chain Lubrication

Warning: This procedure requires trained personnel with PPE!

Is the drive chain pre-lubricated from the manufacturer?

If not, apply initial lubrication before proceeding.

Enter the hours of operation since last lubrication

Enter the date of last lubrication

Select the type of oil used for lubrication

Was the chain generously lubricated with a brush?

Note: The proper viscosity of lubricant greatly affects its ability to flow into the internal areas of the chain.

Select the operating conditions

Parts for Hytrol Belt Conveyor SBI

Access the parts list for your equipment in MaintainX.

Speed Reducer 4AC-RH-30:1 Ratio

R-00153-30R

Motor-C-Face 2 HP-230/460 VAC-3 Ph .- 60 Hz. TEFC

030.7534

Sprocket-Reducer 50B14 x 1 in. Bore (4AC)

028.133

Brake Kit (Used only an Madel RBI) 1/2- 1 HP

031.27595

11/16 in. Hex Idler Bracket

B-04842

Speed Reducer 4AC-RH-30:1 Ratio

R-00153-30R

Motor-C-Face 2 HP-230/460 VAC-3 Ph .- 60 Hz. TEFC

030.7534

Sprocket-Reducer 50B14 x 1 in. Bore (4AC)

028.133

Brake Kit (Used only an Madel RBI) 1/2- 1 HP

031.27595

11/16 in. Hex Idler Bracket

B-04842

Speed Reducer 4AC-RH-30:1 Ratio

R-00153-30R

Motor-C-Face 2 HP-230/460 VAC-3 Ph .- 60 Hz. TEFC

030.7534

Sprocket-Reducer 50B14 x 1 in. Bore (4AC)

028.133

Brake Kit (Used only an Madel RBI) 1/2- 1 HP

031.27595

11/16 in. Hex Idler Bracket

B-04842

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX