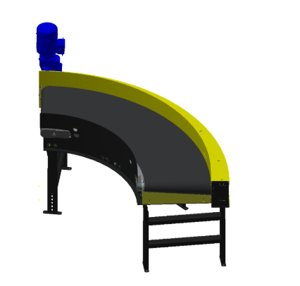

The Hytrol High Speed Sortation Conveyor Prosort 122 is a robust and efficient solution for high-volume material handling. Designed for reliability and speed, this conveyor system optimizes sorting processes in various industrial applications, ensuring smooth operations and minimal downtime.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol High Speed Sortation Conveyor Prosort 122

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol High Speed Sortation Conveyor Prosort 122

Create an account to install this asset package.

Maintenance Plans for Hytrol High Speed Sortation Conveyor Model Prosort 122

Integrate maintenance plans directly into your work orders in MaintainX.

10 Weekly High Speed Sortation Conveyor Lubrication

BEARINGS

Type of bearing

RECOMMENDED CHAIN LUBRICANT

Type of oil used for chain lubrication

REDUCERS

Reducer manufacturer recommendations

OILER BRUSH ADJUSTMENT

Oiler brush comes in contact with the chain

Adjusting nuts and support brackets used

3 Monthly High Speed Sortation Conveyor Check

Reducer:

Check Oil Level

Carrying Chains Sprockets:

Check Alignment with Chain Guards

Carrying Chain Guides:

Check for Wear;

1 Monthly High Speed Sortation Conveyor Check

Motor:

Check Noise

Check Mounting Bolts

Reducer:

Check Noise

Check Temperature

Carrying Chains:

Check Tension

Structural:

1 Weekly High Speed Sortation Conveyor Check

Motor:

Check Temperature

Carrying Chains:

Check Lubrication

Slat/Shoe Assemblies:

Check Physical Condition

Check Operation

Divert Switches:

Check Physical Condition

Electric Divert Switch Checklist

NOTE: All electric divert servo motors are paired with the associated drives at the factory. Connecting motors to the wrong drive may have an adverse effect on the divert operation and could result in physical damage to the sorter. Always connect the drives to the factory paired motors to prevent damage.

Diverts are fully in either the home or diverted position

Diverts are in the home position after removing the enable signal to the Smart Prox and flagging the Smart Prox to trigger a move operation

Each time diverts are powered on, the diverter moves slowly until it finds the home position

The “All Systems Go” signal is on before running the sorter

The Smart Prox is set properly. The face of the prox should be set just out of the shoe pin guide path in the switch guide

Sign off on the Electric Divert Switch Checklist

Parts for Hytrol High Speed Sortation Conveyor Prosort 122

Access the parts list for your equipment in MaintainX.

Side Angle- Drive, Outside (LH or RH)

PT-144126

1/2-13 Hex Jam Nut

041.201

Proximity Switch

032.2116

Take-up Weldment

WA-041286

Sheave - 1A, 8.95"OD X 1-1/2" bore

020.150

Side Angle- Drive, Outside (LH or RH)

PT-144126

1/2-13 Hex Jam Nut

041.201

Proximity Switch

032.2116

Take-up Weldment

WA-041286

Sheave - 1A, 8.95"OD X 1-1/2" bore

020.150

Side Angle- Drive, Outside (LH or RH)

PT-144126

1/2-13 Hex Jam Nut

041.201

Proximity Switch

032.2116

Take-up Weldment

WA-041286

Sheave - 1A, 8.95"OD X 1-1/2" bore

020.150

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX