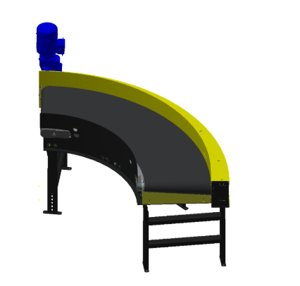

The Hytrol Conveyor TR is a robust industrial conveyor system designed for efficient material handling. Known for its reliability and versatility, this model is ideal for various applications in manufacturing and distribution environments. Regular maintenance ensures optimal performance and longevity of the Hytrol TR conveyor.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol Hytrol Conveyor TR

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol Hytrol Conveyor TR

Create an account to install this asset package.

Maintenance Plans for Hytrol Hytrol Conveyor Model TR

Integrate maintenance plans directly into your work orders in MaintainX.

Maintenance Safety Precautions

Maintenance, such as lubrication and adjustments, shall be performed only by qualified and trained personnel.

It is Important that a maintenance program be established to insure that all conveyor components are maintained in a condition which does not constitute a hazard to personnel.

When a conveyor is stopped for maintenance purposes, starting devices or powered accessories shall be locked or tagged out in accordance with a formalized procedure designed to protect all person or groups involved with the conveyor against an unexpected start.

Replace all safety devices and guards before starting equipment for normal operation.

Whenever practical, DO NOT lubricate conveyors while they are in motion. Only trained personnel who are aware of the hazard of the conveyor in motion shall be allowed to lubricate.

Sign here to confirm you understand and will follow these safety precautions.

2080 Hourly / 6 Monthly Lubrication

Warning: This lubrication process requires trained personnel with PPE!

Enter the machine's hour meter reading

Enter the date of the last lubrication

Is the drive chain pre-lubricated from the manufacturer?

Choose the type of lubricant used

Was a brush used to generously lubricate the chain?

Enter the viscosity of the lubricant used

Sign off on the lubrication process

Drive Chain Alignment and Tension Maintenance

Warning: This procedure requires trained personnel with PPE!

Chain guard removed

Upload a photo of the sprocket alignment

Sprocket alignment checked

Set screws loosened and adjusted

Motor base bolts loosened

Enter the chain tension

Mounting bolts re-tightened

Chain lubricated

Belt Tracking Inspection

Pre-Tracking Inspection

Conveyor is level across the width and length of unit

Drive Pulley, Tail Pulley, Snub Idlers, and all Return Idlers are square with conveyor bed

Belt has been properly threaded through conveyor

Check for improper loading. Feed should be in direction of belt travel, centered on belt

Belt lacing has been installed correctly and is square with the belt

How to Steer the Belt

Condition 1: Belt is running in the direction (FLOW) with the arrow, but tracking (drifting) towards Side “X”

Condition 2: Belt is running in the direction (FLOW) with the arrow, but tracking (drifting) towards Side “Y”

Parts for Hytrol Hytrol Conveyor TR

Access the parts list for your equipment in MaintainX.

Hex Jam Nut-Heavy

041.300

Floor Support Frame

B-02098

Floor Support Frame

B-00925

Drive Plate Assembly

B-21422-R

Chain Guard Front Plate

B-02308

Hex Jam Nut-Heavy

041.300

Floor Support Frame

B-02098

Floor Support Frame

B-00925

Drive Plate Assembly

B-21422-R

Chain Guard Front Plate

B-02308

Hex Jam Nut-Heavy

041.300

Floor Support Frame

B-02098

Floor Support Frame

B-00925

Drive Plate Assembly

B-21422-R

Chain Guard Front Plate

B-02308

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX