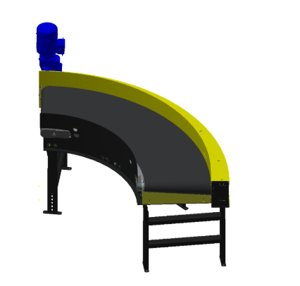

The Hytrol Conveyor SB is a robust and efficient conveyor system designed for industrial applications. Known for its reliability and versatility, this model from Hytrol enhances material handling processes, ensuring smooth operation and minimal downtime in various manufacturing environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol Hytrol Conveyor SB

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol Hytrol Conveyor SB

Create an account to install this asset package.

Maintenance Plans for Hytrol Hytrol Conveyor Model SB

Integrate maintenance plans directly into your work orders in MaintainX.

Monthly Maintenance

Check Motor Noise

Check Motor Mounting Bolts

Check Reducer Noise

Check Reducer Temperature

Check Belt Tracking

Check Belt Tension

Check Bearings Noise

Check V-BeltsTension

Check V-Belts for Wear

Quarterly Maintenance

Reducer Oil Level Check

Drive Chain Tension Check

Drive Chain for Wear Check

Sprockets for Wear Check

Sprockets Set Screws & Keys Check

Bearings Mounting Bolts Check

Sign off on the quarterly maintenance

Maintenance Safety Precautions

Maintenance, such as lubrication and adjustments, shall be performed only by qualified and trained personnel.

It is Important that a maintenance program be established to insure that all conveyor components are maintained in a condition which does not constitute a hazard to personnel.

When a conveyor is stopped for maintenance purposes, starting devices or powered accessories shall be locked or tagged out in accordance with a formalized procedure designed to protect all person or groups involved with the conveyor against an unexpected start.

Replace all safety devices and guards before starting equipment for normal operation.

Whenever practical, DO NOT lubricate conveyors while they are in motion. Only trained personnel who are aware of the hazard of the conveyor in motion shall be allowed to lubricate.

SAFETY GUARDS: Maintain all guards and safety devices IN POSITION and IN SAFE REPAIR.

WARNING SIGNS: Maintain all warning signs in a legible condition and obey all warnings. See Safety Manual for examples of warning signs.

Sign here to confirm you have read and understood the safety precautions

2080 Hourly /6 Monthly Maintenance

Drive Chain Lubrication

The drive chain is pre-lubricated from the manufacturer by a hot dipping process that ensures total lubrication of all components. However, continued proper lubrication will greatly extend the useful life of every drive chain.

Drive Chain lubrication serves several purposes including: • Protecting against wear of the pin-bushing joint • Lubricating chain-sprocket contact surfaces • Preventing rust or corrosion

For normal operating environments, lubricate every 2080 hours of operation or every 6 months, whichever comes first. Lubricate with a good grade of petroleum or synthetic oil (i.e., Shell Rotella or Mobil 1). For best results, always use a brush to generously lubricate the chain.

The proper viscosity of lubricant greatly affects its ability to flow into the internal areas of the chain. Refer to the table below for the proper viscosity of lubricant for your application.

Enter the current hours of operation

Enter the date of the last lubrication

Was the chain lubricated properly?

Enter the type of lubricant used

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX