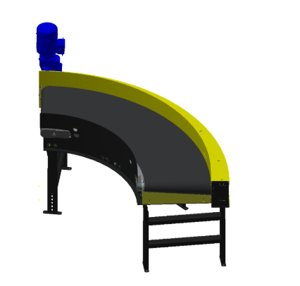

The Hytrol Conveyor 190-LRS is a reliable and efficient conveyor system designed for various industrial applications. Known for its durability and performance, this model from Hytrol enhances material handling processes, ensuring smooth operations in manufacturing and distribution environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol Hytrol Conveyor 190-LRS

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol Hytrol Conveyor 190-LRS

Create an account to install this asset package.

Maintenance Plans for Hytrol Hytrol Conveyor Model 190-LRS

Integrate maintenance plans directly into your work orders in MaintainX.

External Slave Drive Replacement

Sprockets and chain guard back plate removed

Conveyors fastened together with butt couplings and pivot plates

Chain guard back plate attached to bottom of conveyor frame

Sprockets and keys installed on shafts and aligned

Chain installed around sprockets and connecting link inserted

Chain tightened by adjusting take-up block

Chain guard front plate installed

Sign off on the external slave drive replacement

Belt Replacement

Check Overall frame Width (OAW) (figure 8B)

Determine degree of curve or spur

Enter the correct replacement number from the Parts List (Pages 14-23)

TO REPLACE BELT

Note how existing belt is installed

Remove all tread rollers

Replace belt and all rollers

Adjust belt tension per instructions on page 9

The models “LRC” & “LRS” have a take-up bracket located near the center on the underside of the conveyor.

Drive Chain Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Chain guard removed

Sprocket alignment checked

Set screws loosened and adjusted

Chain tension adjusted

Mounting bolts re-tightened

Chain lubricated

Chain guard replaced

Sign off on the drive chain maintenance

2080 Hourly / 6 Monthly Lubrication

Warning: This lubrication procedure requires trained personnel with PPE!

Drive chain pre-lubricated from the manufacturer?

If not, report the issue to the maintenance team and stop the procedure

Choose the type of lubricant used

Enter the viscosity of the lubricant

Check all that apply

If any of the above conditions are present, lubricate more frequently

Enter any additional notes or observations

Sign off on the lubrication procedure

Parts for Hytrol Hytrol Conveyor 190-LRS

Access the parts list for your equipment in MaintainX.

Motor - Foot Mounted

030.2034

Speed Reducer

R-00152-20R

Speed Reducer

R-00152-20L

Sprocket - Reducer

028.1005

Motor Base Assembly (Specify BR)

B-08544

Motor - Foot Mounted

030.2034

Speed Reducer

R-00152-20R

Speed Reducer

R-00152-20L

Sprocket - Reducer

028.1005

Motor Base Assembly (Specify BR)

B-08544

Motor - Foot Mounted

030.2034

Speed Reducer

R-00152-20R

Speed Reducer

R-00152-20L

Sprocket - Reducer

028.1005

Motor Base Assembly (Specify BR)

B-08544

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX