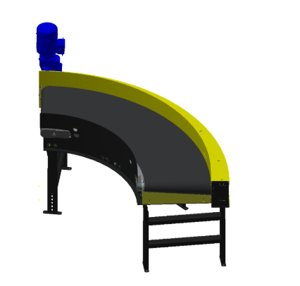

The Hytrol High Speed Sortation Conveyor Prosort 100 Elite is a state-of-the-art conveyor system designed for efficient sorting and distribution in industrial environments. This model enhances operational productivity with its advanced technology and robust construction, making it ideal for high-volume material handling applications.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hytrol High Speed Sortation Conveyor Prosort 100 Elite

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hytrol High Speed Sortation Conveyor Prosort 100 Elite

Create an account to install this asset package.

Maintenance Plans for Hytrol High Speed Sortation Conveyor Model Prosort 100 Elite

Integrate maintenance plans directly into your work orders in MaintainX.

Electric Divert Switch Check

NOTE: All electric divert servo motors are paired with the associated drives at the factory. Connecting motors to the wrong drive may have an adverse effect on the divert operation and could result in physical damage to the sorter. Always connect the drives to the factory paired motors to prevent damage.

Diverts are fully in either the home or diverted position

Diverts are in the home position after removing the enable signal to the Smart Prox and flagging the Smart Prox to trigger a move operation

Each time diverts are powered on, the diverter moves slowly until it finds the home position

“All Systems Go” signal is on before running the sorter

Smart Prox is set properly. The face of the prox should be set just out of the shoe pin guide path in the switch guide

Upload a photo of the Smart Prox setting

Sign off on the Electric Divert Switch Check

1 Monthly High Speed Sortation Conveyor Check

Motor:

Check Noise

Check Mounting Bolts

Reducer:

Check Noise

Check Temperature

Carrying Chains:

Check Tension

Structural:

10 Weekly High Speed Sortation Conveyor Lubrication

BEARINGS:

A) NO GREASE FITTING - Prelubricated - No lubrication required.

B) WITH GREASE FITTING - Relubricate approximately every 10 to 12 weeks with lithium base grease suitable for ball bearing service.

RECOMMENDED CHAIN LUBRICANT:

A good grade of clean non-detergent petroleum or synthetic oil is recommended. See chart for proper viscosity.

REDUCERS:

See recommendations by manufacturer.

OILER BRUSH ADJUSTMENT:

It is very important that the oiler brush comes in contact with the chain for proper lubrication and increased chain life. This can be done by using the adjusting nuts and support brackets.;

Pneumatic Divert Switch Check

Warning: Ensure all ProSort sections are installed and aligned before proceeding.

Manually pivot the switch back and forth between the non-divert and divert position checking for a free and smooth pivoting movement.

Describe any switch binding issues and remedies applied.

Switch adjustment necessary?

If switch adjustment is necessary, loosen the jam nut on the cylinder rod. Screw cylinder rod into or out of rod end to adjust the switch and retighten jam nut.

Is air pressure on and each divert switch in, or moves to, the home (non-divert) position (Figure 8C)?

Is the smart prox set properly? The face of the prox should be set just out of the shoe pin guide path in the switch guide (Figure 8B).

Sign off on the Pneumatic Divert Switch Check

1 Weekly High Speed Sortation Conveyor Check

Motor:

Check Temperature

Carrying Chains:

Check Lubrication

Slat/Shoe Assemblies:

Check Physical Condition

Check Operation

Divert Switches:

Check Physical Condition

Parts for Hytrol High Speed Sortation Conveyor Prosort 100 Elite

Access the parts list for your equipment in MaintainX.

Y-Plug Cable Connector

032.21124

1/4-20 NC2B Hex Locknut-Nylon Insert,ZP

041.800

Plastic Tee-1/2 in. PLST-1/2 in. PLST-1/2 in. PLST

094.14089

Brass Conn-Straight Male, 1/8 in. NPT-3/8 in. PLS

094.14015

#10-24 X 1-3/4 in. LG Hex Skt FIt HD Cap Screw

042.6515

Y-Plug Cable Connector

032.21124

1/4-20 NC2B Hex Locknut-Nylon Insert,ZP

041.800

Plastic Tee-1/2 in. PLST-1/2 in. PLST-1/2 in. PLST

094.14089

Brass Conn-Straight Male, 1/8 in. NPT-3/8 in. PLS

094.14015

#10-24 X 1-3/4 in. LG Hex Skt FIt HD Cap Screw

042.6515

Y-Plug Cable Connector

032.21124

1/4-20 NC2B Hex Locknut-Nylon Insert,ZP

041.800

Plastic Tee-1/2 in. PLST-1/2 in. PLST-1/2 in. PLST

094.14089

Brass Conn-Straight Male, 1/8 in. NPT-3/8 in. PLS

094.14015

#10-24 X 1-3/4 in. LG Hex Skt FIt HD Cap Screw

042.6515

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX