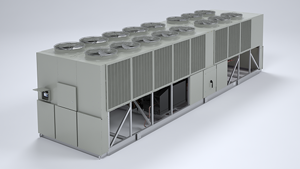

The Hyster-Yale Lift Truck W45ZHD3 is a robust and reliable forklift designed for heavy-duty applications. Known for its exceptional maneuverability and lifting capabilities, this model is ideal for warehouses and industrial environments, ensuring efficient material handling and productivity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Hyster-Yale Hyster-Yale Lift Truck W45ZHD3 W45ZHD3

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hyster-Yale Hyster-Yale Lift Truck W45ZHD3 W45ZHD3

Create an account to install this asset package.

Maintenance Plans for Hyster-Yale Hyster-Yale Lift Truck W45ZHD3 Model W45ZHD3

Integrate maintenance plans directly into your work orders in MaintainX.

2000 Hourly / 2 Yearly Lift Truck Maintenance

Load Wheel Bearings - Disassemble, clean, and inspect for wear or damage. Pack the bearings with grease and assemble.

Drive Unit Gear Oil - Keep truck level. Place a drip pan under front end of the truck and drain the oil. Remove drive unit cover. Remove drain and fill plugs to drain gear oil. Replace drain. Add gear oil through fill plug until oil runs out. Replace fill plug. Drive unit capacity is 0.18 liter (6 oz). DO NOT OVERFILL.

Hydraulic System - Lower the forks. Remove the drive unit cover. Remove the reservoir. Empty hydraulic oil into a suitable container and discard in accordance with local regulations. Clean the hydraulic reservoir using a suitable cleaning solution and dry with compressed air. Clean and inspect the strainer. Replace the strainer if clogged or damaged. Make sure reservoir is clean and dry. Install the reservoir.

To Fill Hydraulic Reservoir

Lower the forks. Remove the breather filler cap. Add hydraulic oil through the breather filler pipe until at Max Mark on reservoir. Capacity is approximately 0.95 liter (1.0 qt). Install the breather cap and tighten. Raise and lower the forks, while bringing oil to normal operating temperature. Then recheck hydraulic oil level. DO NOT OVERFILL.;

2000 Hourly Lift Truck Maintenance

Clean and Repack Load Wheel Bearings

Inspect Contactors - Tips and Wire Connections - Tightness and Corrosion

Replace All Bolts, Nuts, Cotter Pins, Etc.

Sign off on the lift truck maintenance

350 Hourly Lift Truck Maintenance

Lubricate - Chassis (All Fittings)

Inspect All Linkage and Load Wheels

Hydraulic Reservoir Oil Level

Inspect Hydraulic Reservoir Breather

Inspect Caster Wheel Clearance

Drive Unit Oil Level

Inspect Hydraulic Pump for Noise and Operation

Inspect Hydraulic Control Valve for Leaks and Operation

Inspect Relief Valve Settings

8 Hourly / 1 Daily Lift Truck Check

Hydraulic Fluid Leaks

Tires Condition

Forks Condition

Load Backrest for Cracks and Mounting

Hydraulic Hoses and Fittings for Leaks and Damaged or Defective Components

Attached Safety Warnings

Battery - Water/Electrolyte Level and Charge

Hydraulic Reservoir Fluid Level

Operating Manual in Container

350 Hourly / 6 Monthly Lift Truck Maintenance

Refer to Capacities and Specifications 8000 SRM 1010 for proper specifications on lubrication requirements for the lubrication fittings. Clean the lubrication fittings before and after lubricating. See Figure 8.

Check Hydraulic Oil Level

Hydraulic System Check - Check the hydraulic oil level when the oil is at normal operating temperature and forks are in the lowered position.

Remove drive unit cover. Remove breather cap from hydraulic pump and reservoir. Add hydraulic oil, if necessary, through the breather filler pipe until oil is at Full mark on reservoir. Install breather cap and tighten. DO NOT OVERFILL.

Hydraulic Reservoir Breather - Remove drive unit cover. Remove breather and clean with a suitable cleaning solution, blow dry with compressed air, and install. Replace breather if it cannot be cleaned or is damaged.

Drive Unit (Initial 350 hour check) - Keep truck level. Place a drip pan under front end of the truck and drain the oil. Remove drive unit cover. Remove drain and fill plugs to drain gear oil. Replace drain. Add gear oil through fill plug until oil runs out. Replace fill plug. Drive unit capacity is 0.18 liter (6 oz). DO NOT OVERFILL.

Drive Unit - With the truck level, remove the fill plug and check the oil level, add gear oil until full. DO NOT OVERFILL.;

Parts for Hyster-Yale Hyster-Yale Lift Truck W45ZHD3 W45ZHD3

Access the parts list for your equipment in MaintainX.

Parking Brake

4073944

Washer

375629

Screw

4010126

Master Drive Unit Assembly

4626898

Pin

4010120

Parking Brake

4073944

Washer

375629

Screw

4010126

Master Drive Unit Assembly

4626898

Pin

4010120

Parking Brake

4073944

Washer

375629

Screw

4010126

Master Drive Unit Assembly

4626898

Pin

4010120

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX