Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

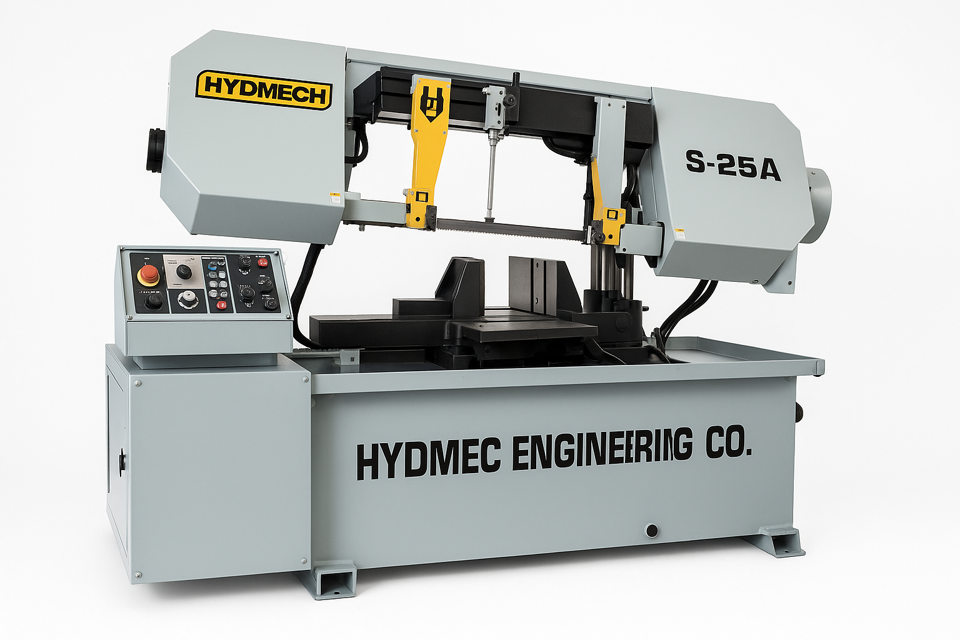

Manual for Hyd‑Mech Group Bandsaw S-25A

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

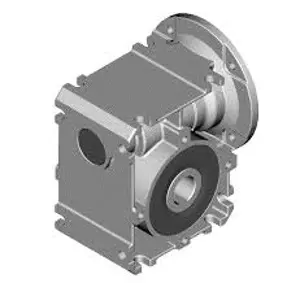

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hyd‑Mech Group Bandsaw S-25A

Create an account to install this asset package.

Maintenance Plans for Hyd‑Mech Group Bandsaw Model S-25A

Integrate maintenance plans directly into your work orders in MaintainX.

Bandsaw Cleaning

CLEANLINESS

The S-25A series design should endure heavy operating conditions and provide the customer with flawless machine performance. To extend good performance some care is required, especially cleanliness.

The following areas should be kept clean of dirt, grease and chips:

-CONTROL CONSOLE

-OUTFEED TABLE

-DOOR CHARTS

-LARGE BUILD UP OF CHIPS IN THE SAW BASE

-WHEEL BOXES

-VISE WAYS

Blade Brush Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Is the blade brush worn out to approximately 70% of its original diameter 3 \ OD?"

If the blade brush is worn out, replace it. A brush may be purchased through a HYD-MECH dealer in your area.

Did you loosen the nut on the adjusting screw?

Did you turn the screw counter clockwise until wires from the brush touch the bottom of the blade gullets?

Sign off on the blade brush maintenance

Hydraulic Maintenance

OIL LEVEL - Oil level should be maintained in the upper half of the level gauge. Normally the rate of oil consumption will be very low and it should be unnecessary to add oil more often than at filter changes. Add oil only to the top line on level gauge.

The S-25A is shipped from the factory with Valvoline 150-46 hydraulic oil. Generally any brand of recognized mineral hydraulic oil with the same properties should be compatible with Valvoline 150-46, but to avoid any risk we suggest staying with Valvoline 150-46.

If it is desired to change brands, it is necessary to drain the tank and 1/3 refill it with the new oil, operate through several automatic cycles with the index set to full stroke and head to full rise, drain the tank again, and finally fill the tank with the new brand.

Hydraulic tank capacity is approximately 17 US gallons.

OIL TEMPERATURE - Oil temperature is indicated by a thermometer contained in the level gauge.

Oil temperature during steady operation should stabilize at about 50 - 55 F° above room temperature. Thus in a 70 F° shop one might expect an oil temperature of about 120 F°. Oil temperature should never exceed 160 F°.

SYSTEM PRESSURE - System pressure is factory set to 900 ± 25 psi and should not require further attention except precautionary observation at start-up and occassionally thereafter.

BLADE TENSION - Is controlled by system pressure.

VISE PRESSURE - Is controlled by system pressure. If machine is equipped with the optional variable vise pressure; vise pressure is operator adjustable.

Blade Replacement

Select manual mode and raise the head slightly (about two inches at the drive side guide arm)

Open the idler and drive doors

Remove the blade guard

Release the carbide guides

Release the blade tension by positioning the blade tension selector switch to '-'

TURN THE HYDRAULICS OFF

Push the blade out from between the carbide guides

Remove the blade

Install a new blade. The teeth should be facing away from the head of the saw. The teeth on the part of the blade between the two guide blocks should point towards the drive side of the head

Parts for Hyd‑Mech Group Bandsaw S-25A

Access the parts list for your equipment in MaintainX.

Head Cylinder

S25-C4-00

Shuttle Cylinder

S25-C1-00

Blade Tension Cylinder

S25-C5-00

Vice Cylinders

S25-C3-00

Head Swing Cylinder

S25-C9-00

Head Cylinder

S25-C4-00

Shuttle Cylinder

S25-C1-00

Blade Tension Cylinder

S25-C5-00

Vice Cylinders

S25-C3-00

Head Swing Cylinder

S25-C9-00

Head Cylinder

S25-C4-00

Shuttle Cylinder

S25-C1-00

Blade Tension Cylinder

S25-C5-00

Vice Cylinders

S25-C3-00

Head Swing Cylinder

S25-C9-00

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX