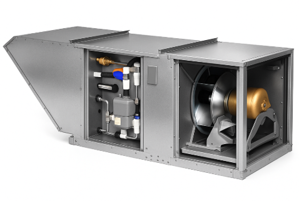

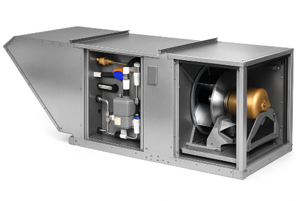

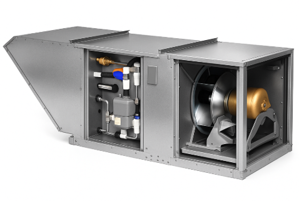

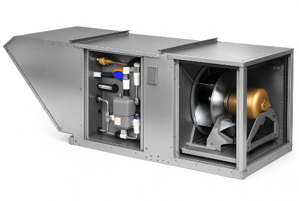

The Greenheck Warehouse Make Up Air Unit DGX-125-H35-DB is a high-efficiency air handling solution designed for optimal indoor air quality. This unit effectively manages ventilation and temperature control, making it ideal for warehouses and industrial applications. Experience reliable performance and energy savings with this advanced air unit from Greenheck.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Greenheck Warehouse Make Up Air Unit DGX-125-H35-DB

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Greenheck Warehouse Make Up Air Unit DGX-125-H35-DB

Create an account to install this asset package.

Maintenance Plans for Greenheck Warehouse Make Up Air Unit Model DGX-125-H35-DB

Integrate maintenance plans directly into your work orders in MaintainX.

Blowing-Out Coils

Close valves on the supply and return lines

Open drain valves and/or drain plug

Remove vent plug to allow coil to drain faster

After coil is fully drained, connect a blower to the caps. Do not connect the blower to the air vent or drain plug

Close the vent plug on the header that the blower is connected to. Open the drain valve or cap on the other header

Turn on blower for 30 minutes

Place mirror at discharge. If the mirror fogs up, repeat procedure until no fog appears on the mirror

After drying the coil, wait a few minutes then repeat Step #5

Leave drains open and do not install plugs until beginning of cooling season;

Motor Maintenance

Motor maintenance is generally limited to cleaning and lubrication (where applicable)

Limit cleaning to exterior surfaces only. Removing dust and grease build-up on the motor assures proper motor cooling

Grease motors supplied with grease fittings in accordance with the manufacturer’s recommendations

Do not allow water or solvents to enter the motor or bearings. Never spray motors and bearings with steam, water or solvents

Greasing motors is only intended when fittings are provided. Many motors are permanently lubricated, requiring no additional lubrication;

1 Yearly Gas Train Check

Check the gas connections, joints and valves annually for tightness

Apply a soap and water solution to all piping

Watch for bubbling which indicates a leak;

Fan Bearing Lubrication

Fan bearings are carefully selected to match the maximum load and operating conditions of the specific class, arrangement and fan size

The instructions provided in this manual and those provided by the bearing manufacturer will minimize any bearing problems

Lubricate bearings prior to periods of extended shutdowns or storage and rotate shaft monthly to aid in corrosion prevention

If the fan is stored more than three months, purge the bearings with new grease prior to start-up;

Chilled Water Coil Maintenance

Test the circulating fluid for sediment, corrosive products and biological contaminants. Take the necessary corrective measures

Maintain adequate fluid velocities and proper filtering of the fluid

If automatic air vents are not utilized, periodic venting of the coil is recommended to remove accumulated air;

Parts for Greenheck Warehouse Make Up Air Unit DGX-125-H35-DB

Access the parts list for your equipment in MaintainX.

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 3/4"

461264

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX