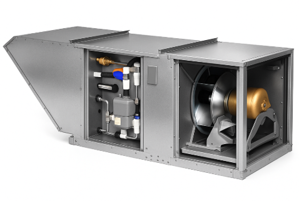

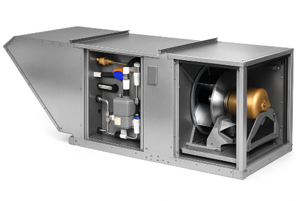

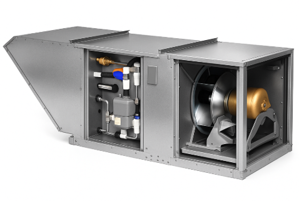

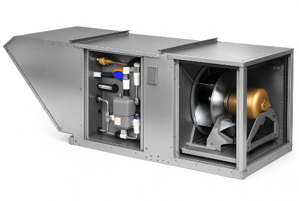

The Greenheck Warehouse Make Up Air Unit DGX-115 is designed for efficient air circulation and temperature control in industrial settings. This robust unit ensures optimal indoor air quality while minimizing energy consumption, making it an ideal choice for warehouses and large facilities.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Greenheck Warehouse Make Up Air Unit DGX-115

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Greenheck Warehouse Make Up Air Unit DGX-115

Create an account to install this asset package.

Maintenance Plans for Greenheck Warehouse Make Up Air Unit Model DGX-115

Integrate maintenance plans directly into your work orders in MaintainX.

Fan Bearing Lubrication

Warning: Ensure the fan is turned off and disconnected from power before starting the procedure.

Fan bearings are carefully selected to match the maximum load and operating conditions of the specific class, arrangement and fan size.

The instructions provided in this manual and those provided by the bearing manufacturer will minimize any bearing problems.

Is the fan disconnected from power?

Are the bearings in good condition?

Enter the amount of lubricant used

Was the shaft rotated monthly?

If the fan is stored more than three months, purge the bearings with new grease prior to start-up.

Sign off on the fan bearing lubrication

Supply Wheel Service

Warning: This service requires trained personnel with PPE!

Is there oil and dust accumulation on the wheel?

If there is oil and dust accumulation, proceed with the cleaning procedure

Was the wheel cleaned properly?

Was the housing cleaned properly?

Enter the balance reading of the wheel after cleaning

Sign off on the supply wheel service

Cooling Coil Maintenance

Repair and replacement of the coil and the connecting piping, valves, etc., must be performed by a qualified individual

Inspect the coil for signs of corrosion and/or leaks

Repair any leaks as required

Inspect the coil’s surface for foreign material. If the coil surface needs cleaning, clean the coil from the leaving air-side so that foreign material will be washed out of the coil rather than pushed farther in

Inspect and clean the drain pan to prevent the growth of algae and other organisms

Be sure to read and follow the coil manufacturer’s recommendations before using any cleaning fluid

Caution must be used to avoid injury when venting the coil

High pressure and/or high temperature fluids can cause serious injuries

Sign off on the cooling coil maintenance

Filter Maintenance

Filter maintenance is generally limited to cleaning and replacement.

If aluminum mesh filters are installed, are they clean?

If aluminum mesh filters are installed, they can be washed in warm soapy water.

Did you add an adhesive spray to aluminum mesh filters to increase their efficiency?

If disposable filters are installed, can light pass through the filter?

If disposable filters are installed, they can be checked by holding up to a light source. If light cannot pass through the filter, it must be replaced.

When reinstalling filters, did you install them with the airflow in the correct direction?

An airflow direction arrow is located on the side of the filters.

Are replacement filters from the same manufacturer and the same size as the original filters provided with the unit?

V-Belt Drive Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Check for wear, tension, alignment, and dirt accumulation

Measure the deflection in the belt

Check the alignment using a straight edge across both sheaves

Account for differences in sheave width

Check for premature or frequent belt failures

Check for abnormally high belt tension or drive misalignment

Check for abnormally low belt tension

Ensure belts are not pried on or off the sheave

Parts for Greenheck Warehouse Make Up Air Unit DGX-115

Access the parts list for your equipment in MaintainX.

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 1/4"

461263

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX