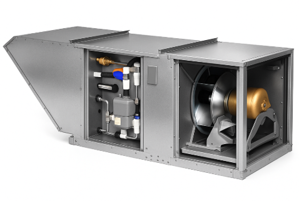

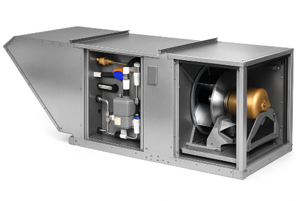

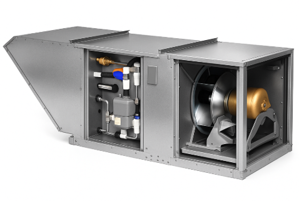

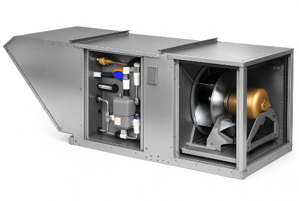

The Greenheck Warehouse Make Up Air Unit DGX-110 is a high-efficiency air handling solution designed to provide optimal indoor air quality. This unit effectively manages ventilation and temperature control, making it ideal for various industrial applications. Experience reliable performance and energy savings with this advanced air unit from Greenheck.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Greenheck Warehouse Make Up Air Unit DGX-110

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Greenheck Warehouse Make Up Air Unit DGX-110

Create an account to install this asset package.

Maintenance Plans for Greenheck Warehouse Make Up Air Unit Model DGX-110

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Gas Train Check

Warning: This procedure should be performed by trained personnel only!

Gas connections, joints and valves are tight

Upload a photo of the applied soap and water solution to all piping

Any bubbling observed?

Sign off on the gas train check

Fan Bearing Lubrication

Warning: Ensure the fan is turned off and disconnected from power before starting the procedure.

Note: Lubricate bearings prior to periods of extended shutdowns or storage and rotate shaft monthly to aid in corrosion prevention.

Fan turned off and disconnected from power?

Bearings selected to match the maximum load and operating conditions?

Enter the current load on the fan

Enter the current operating conditions of the fan

Bearings lubricated prior to extended shutdowns or storage?

Shaft rotated monthly?

If the fan is stored more than three months, purge the bearings with new grease prior to start-up.

Evaporative Cooling Module Maintenance

Media Maintenance

Brushed media lightly with a soft bristle brush while flushing with water?

Reduced the amount of mineral build-up?

Is there a large amount of mineral build-up?

If yes, clean or replace the media and increase the water bleed-off or drain and fill rate.

Reinstalled the evaporative media correctly?

Replacement media must be from the same manufacturer and be the same size as the original media provided with the unit.

Sign off on the evaporative cooling module maintenance

Supply Wheel Service

Warning: This service requires trained personnel with PPE!

Is there oil and dust accumulation on the wheel?

If there is oil and dust accumulation, proceed with the cleaning procedure

Was the wheel cleaned properly?

Was the housing cleaned properly?

Enter the balance reading of the wheel after cleaning

Sign off on the supply wheel service

Motor Maintenance

Warning: Only trained personnel should perform this procedure

Motor exterior cleaned

Motor greased in accordance with manufacturer’s recommendations

Water or solvents entered the motor or bearings?

If water or solvents entered the motor or bearings, report to the maintenance team immediately

Sign off on the motor maintenance

Parts for Greenheck Warehouse Make Up Air Unit DGX-110

Access the parts list for your equipment in MaintainX.

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/2"

461262

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX