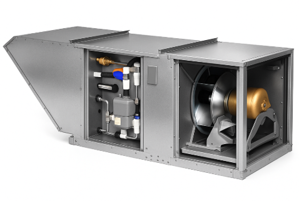

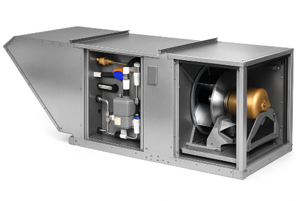

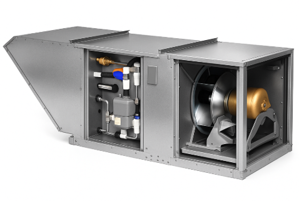

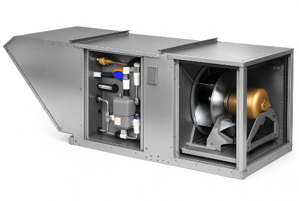

The Greenheck Warehouse Make Up Air Unit DGX-112 is designed for efficient air handling in industrial settings. This robust unit ensures optimal indoor air quality and temperature control, making it essential for warehouses and manufacturing facilities. With reliable performance and easy maintenance, the DGX-112 is a top choice for effective air management solutions.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Greenheck Warehouse Make Up Air Unit DGX-112

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Greenheck Warehouse Make Up Air Unit DGX-112

Create an account to install this asset package.

Maintenance Plans for Greenheck Warehouse Make Up Air Unit Model DGX-112

Integrate maintenance plans directly into your work orders in MaintainX.

Chilled Water Coil Maintenance

Test the circulating fluid for sediment, corrosive products and biological contaminants

Describe the corrective measures taken if any contaminants were found

Maintain adequate fluid velocities and proper filtering of the fluid

Are automatic air vents utilized?

If automatic air vents are not utilized, periodic venting of the coil is recommended to remove accumulated air

Sign off on the chilled water coil maintenance

Supply Wheel Service

Warning: This service requires trained personnel with PPE!

Is the supply wheel operational?

If the supply wheel is not operational, report the issues to the maintenance team and stop the procedure

Check for oil and dust accumulation on the wheel

Upload a photo of the supply wheel before cleaning

Clean the wheel and housing

Upload a photo of the supply wheel after cleaning

Enter the balance reading of the wheel after cleaning

Sign off on the supply wheel service

Blowing-Out Coils

Warning: This procedure should be performed by trained personnel only.

Close valves on the supply and return lines

Open drain valves and/or drain plug

Remove vent plug to allow coil to drain faster

After coil is fully drained, connect a blower to the caps. Do not connect the blower to the air vent or drain plug

Close the vent plug on the header that the blower is connected to. Open the drain valve or cap on the other header

Turn on blower for 30 minutes

Place mirror at discharge. If the mirror fogs up, repeat procedure until no fog appears on the mirror

After drying the coil, wait a few minutes then repeat Step #5

Burner Maintenance

Warning: Ensure the burner is turned off and cooled down before starting the maintenance.

Inspect the burner for accumulation of scale on both the upstream and downstream sides of the mixing plates

Remove foreign material with a wire brush

Visually check that all holes in the mixing plates are clear

If any burner ports are plugged (even partially), clear them with a piece of wire or another appropriate tool. Do not enlarge burner ports when clearing a blockage as performance could be affected

Replace or tighten any loose or missing fasteners on the mixing plates

Always use appropriate fasteners

Inspect and clean the flame rod or UV scanner

Occasional replacement of the flame rod and spark rod may be necessary to ensure optimum unit performance

Evaporative Cooling Module Maintenance

Media Maintenance

Is there a large amount of mineral build-up?

If there is a large amount of mineral build-up, clean or replace the media and increase the water bleed-off or drain and fill rate.

Is the cooling media older than 5 years?

If the cooling media is older than 5 years, replace it.

Select the type of media used for replacement

Sign off on the evaporative cooling module maintenance

Parts for Greenheck Warehouse Make Up Air Unit DGX-112

Access the parts list for your equipment in MaintainX.

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 1/2"

461262

Auto Drain & Fill Valve 3/4"

461264

Auto Drain & Fill Valve 1/4"

461263

Auto Drain & Fill Valve 1/2"

461262

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX