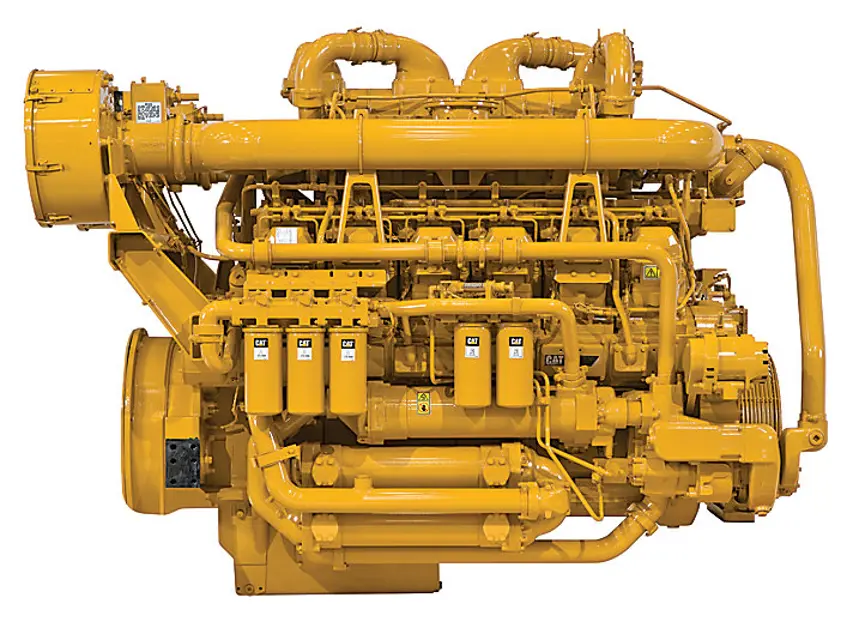

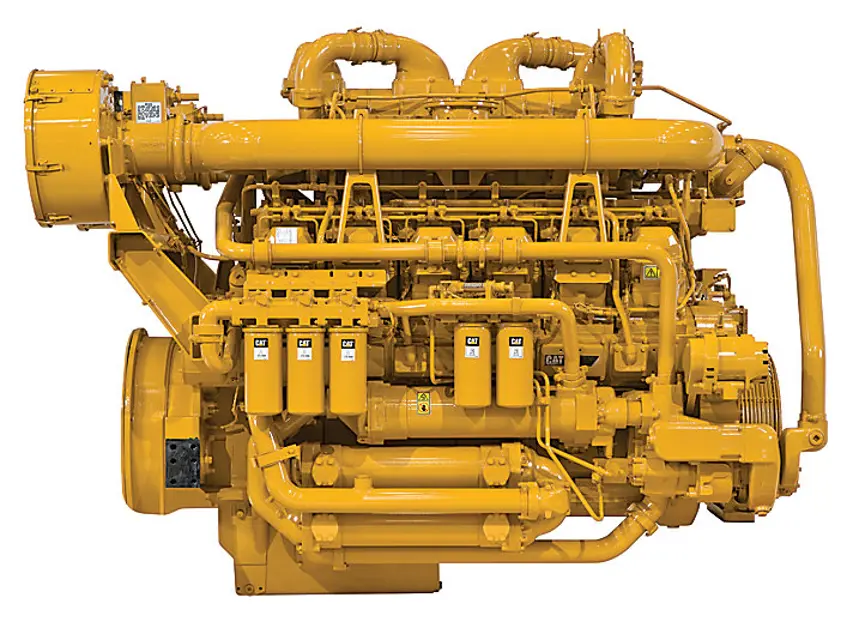

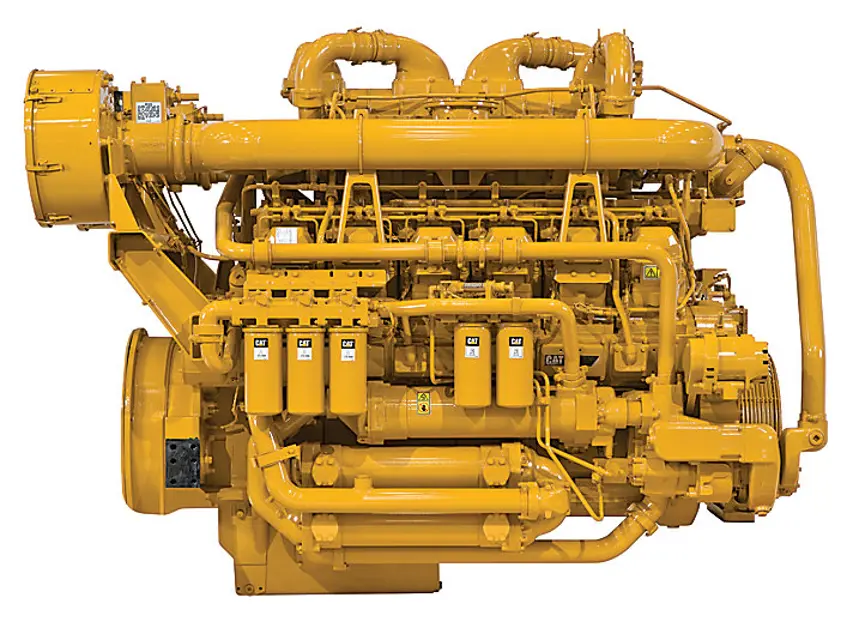

The Caterpillar Diesel Marine Engine 3512 is a robust, high-performance engine designed for marine applications. Known for its reliability and efficiency, this engine is ideal for various marine vessels, providing exceptional power and durability in demanding environments.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Caterpillar Diesel Marine Engine 3512

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Caterpillar Diesel Marine Engine 3512

Create an account to install this asset package.

Maintenance Plans for Caterpillar Diesel Marine Engine Model 3512

Integrate maintenance plans directly into your work orders in MaintainX.

11000 Hours Top End Maintenance

Perform every 11000 hours or 1,460,000 liter (385,500 U.S. gallon) of Fuel Rated Up to 1300 rpm

Inspect Cylinder Heads

Test Injectors

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer;

Sign off on the 11000 Hours Top End Maintenance

1 Daily Lubricators Maintanance

Inspect Air Starting Motor and Air Prelube Pump Lubricators

Adjust the air starting system pressure, if necessary

Fill all air starting system lubricators

NOTICE: Never allow the air lubricator jar to become empty. The starting and prelube pump motors will be damaged by lack of proper lubrication

The vanes of the air starting motor and air prelube pump motor are lubricated with a fine oil mist from the starting motor oiler while the air starting motor is operating

When the air lubricator jar becomes half empty, remove oil filler plug and fill the jar with clean diesel fuel or kerosene.

Refer to the Lubricant Viscosity Recommendations for more information

Sign off on the daily lubricators maintenance

22000 Hours Engine Overhaul

Perform every 22000 hours or 2,920,000 liter (770,000 U.S. gallon) of Fuel Rated Up to 1300 rpm

Inspect/Rebuild or Exchange if necessary Cylinder Heads

Inspect/Rebuild or Exchange if necessary Connecting Rods

Inspect/Rebuild or Exchange if necessary Cylinder Liners

Inspect/Rebuild or Exchange if necessary Pistons

Inspect/Rebuild or Exchange if necessary Turbochargers

Inspect/Rebuild or Exchange if necessary Cam Followers

Inspect/Rebuild or Exchange if necessary Fuel Transfer Pump

Inspect/Rebuild or Exchange if necessary Prelube Pump

1000 Hours Marine Gear Oil Replacement

- Perform every 1000 hours or 133,500 liter (35,000 U.S. gallon) of Fuel Rated Up to 1300 rpm, 164,000 liter (43,200 U.S. gallon) of Fuel Rated 1301 to 1600 rpm, 194,000 liter (51,200 U.S. gallon) of Fuel Rated 1601 to 1800 rpm

- Change oil of Marine Gear

WARNING!

Use caution when draining oil or changing filters

Hot oil or components can cause burns if they contact skin

With the oil warm and the engine stopped, drain the marine gear

1. Remove the marine gear drain plug and allow the oil to drain

2. Clean and install the drain plug

If a Sump Pump is Used to Drain Oil

1000 Hours Marine Gear Breather Cleaning

- Perform every 1000 hours or 133,500 liter (35,000 U.S. gallon) of Fuel Rated Up to 1300 rpm, 164,000 liter (43,200 U.S. gallon) of Fuel Rated 1301 to 1600 rpm, 194,000 liter (51,200 U.S. gallon) of Fuel Rated 1601 to 1800 rpm

- Clean the Marine Gear Breather

1. Remove the breather

2. Clean the breather with clean, nonflammable solvent

3. Install the breather

- Fill the Marine Gear

NOTICE:

Be sure both valves (one to the marine gear and one to the engine oil pan) are closed. Otherwise, a transfer of oil may occur during operation and damage could result

Fill the marine gear to the FULL mark on the oil level gauge. Refer to the Refill Capacities chart for the correct amount of oil

Parts for Caterpillar Diesel Marine Engine 3512

Access the parts list for your equipment in MaintainX.

Silicone Lubricant

5N5561

Torque Screwdriver Tool Group

6V4980

Woodward Governor

UG8L

Hydrosolv 100, 208L (55 U.S. Gal) Drum

8T7571

Cooling System Cleaner Standard Type In The 2 Liter (1/2U.S. Gallon)

6V4511

Silicone Lubricant

5N5561

Torque Screwdriver Tool Group

6V4980

Woodward Governor

UG8L

Hydrosolv 100, 208L (55 U.S. Gal) Drum

8T7571

Cooling System Cleaner Standard Type In The 2 Liter (1/2U.S. Gallon)

6V4511

Silicone Lubricant

5N5561

Torque Screwdriver Tool Group

6V4980

Woodward Governor

UG8L

Hydrosolv 100, 208L (55 U.S. Gal) Drum

8T7571

Cooling System Cleaner Standard Type In The 2 Liter (1/2U.S. Gallon)

6V4511

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX