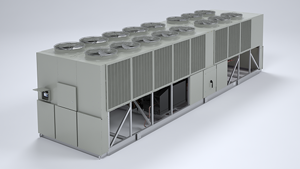

The Trumpf Laser Cutting Machine TRUMATIC L 3050 is a high-performance industrial asset designed for precision cutting applications. Known for its reliability and advanced technology, this machine enhances productivity in various manufacturing processes, making it an essential tool for modern fabrication shops.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Trumpf Laser Cutting Machine TRUMATIC L 3050

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Trumpf Laser Cutting Machine TRUMATIC L 3050

Create an account to install this asset package.

Maintenance Plans for Trumpf Laser Cutting Machine Model TRUMATIC L 3050

Integrate maintenance plans directly into your work orders in MaintainX.

Belt Tensioning Maintenance

CAUTION: ALWAYS DISCONNECT POWER TO CONVEYOR BEFORE ATTEMPTING ANY MAINTENANCE PROCEDURES.

Install belt as stated in Parts and Service Manual, except do not tension belt.

Tighten pillow block bearing bolts, and then loosen five (5) 1⁄4 turns.

Set torque wrench to 25 inch pounds. Tighten each bearing-adjusting bolt alternately until 25 inch pounds is obtained.

Manually rotate belt back and forth.

Repeat steps (3) and (4) until belt rotation no longer results in decreased torque setting.

Lock adjusting bolts.

Run machine for (2) hour break-in period.

Loosen adjusting bolt locknuts. Loosen bearing bolts as noted in step (2). Repeat steps (3), (4) and (5).

Tail Shaft/ Sprocket Weldment Replacement

Power to the conveyor disconnected

Belt removed from the conveyor

Bolt-on tail flange removed from each side of the conveyor

Bearing mounting bolts removed from each bearing on both sides

Tail shaft/sprocket weldment slid from the frame

Bearings and collars transferred to replacement tail shaft/sprocket weldment

Tail shaft/sprocket weldment properly centered in the conveyor frame

Belt reinstalled into the conveyor

Belt located in the center of the frame

Initial 100 Hours Laser Cutting Machine Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Inspect conveyor belt parts for excessive wear

If excessive wear is noted, belt should be removed and repaired. (Refer to service section for belt removal instructions)

Change oil in speed reducer (if applicable)

Refer to gearbox maintenance for proper gear oil

Grease pillow block bearings, using grease gun

Do not over grease or the bearing seals could be damaged

Check belt tension

Sign off on the machine maintenance

Drive Shaft/ Sprocket Weldment Replacement

Power to the conveyor disconnected

Inspection plates under the two pillow block bearings removed

Conveyor run until the master link reaches the inspection slot

Dust cover from the end of the gearmotor removed

10-mm. bolt from the end of the drive shaft removed

4 mounting bolts attaching the gearmotor to the mounting bracket removed and gearmotor removed

Lock nuts on the belt tension adjusting screws loosened and adjusting screws backed off

Two bolts holding each pillow block bearing loosened

Drive shaft slid toward the tail of the conveyor for maximum slack in the belt

Hinge Belt Replacement

Power to the conveyor disconnected

Inspection plates removed

Master link reached the inspection slot

Dust cover removed from the end of the gearmotor

10-mm. bolt removed from the end of the drive shaft

Gearmotor removed

Lock nuts on the belt tension adjusting screws loosened

Pillow block bearing bolts loosened

Drive shaft slid towards the tail of the conveyor

Parts for Trumpf Laser Cutting Machine TRUMATIC L 3050

Access the parts list for your equipment in MaintainX.

Screw, Button-Hd. M6 X 10

97A-1

Side Wing – Left Hand

*75B-72

Washer, Flat M12

75B-60

Cotter

75B-17

Bolt, Hex-Hd. Cap M12 X 45

66M34

Screw, Button-Hd. M6 X 10

97A-1

Side Wing – Left Hand

*75B-72

Washer, Flat M12

75B-60

Cotter

75B-17

Bolt, Hex-Hd. Cap M12 X 45

66M34

Screw, Button-Hd. M6 X 10

97A-1

Side Wing – Left Hand

*75B-72

Washer, Flat M12

75B-60

Cotter

75B-17

Bolt, Hex-Hd. Cap M12 X 45

66M34

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX