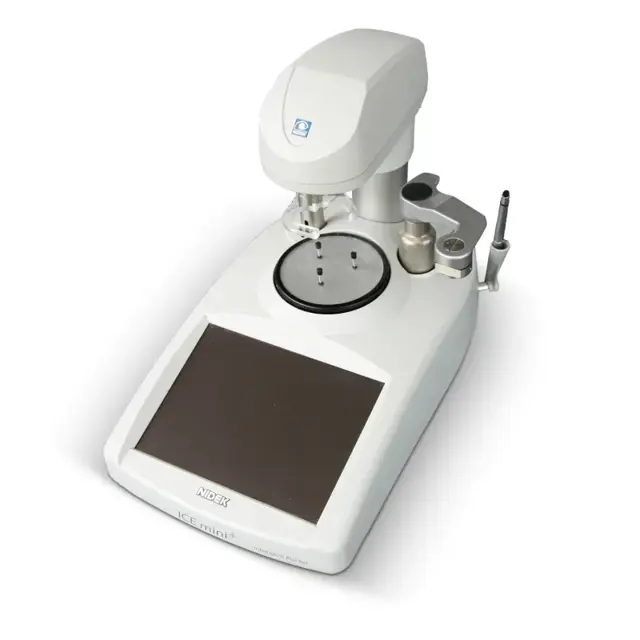

The Nidec Intelligent Blocker ICE mini is a cutting-edge industrial asset designed for efficient operation in various applications. This model combines advanced technology with robust performance, ensuring reliability and ease of maintenance for optimal productivity in your operations.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Nidec Intelligent Blocker ICE mini

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Nidec Intelligent Blocker ICE mini

Create an account to install this asset package.

Maintenance Plans for Nidec Intelligent Blocker Model ICE mini

Integrate maintenance plans directly into your work orders in MaintainX.

Fuse Replacement

CAUTION! Be sure to turn off the power and disconnect the power cord from the outlet before replacing the fuses. Otherwise, electric shock may result.

Only the specified fuses (T 1 A 250 V) must be used. Any fuses other than the specified ones may cause fire.

Power turned off

Power cord removed from the electrical outlet

Power cord unplugged from the inlet

Fuse holder under the inlet removed

Fuses replaced with new ones

Fuse holder put back into its original position

Sign off on the fuse replacement

Intelligent Blocker Cleaning

CAUTION: Never use an organic solvent such as paint thinner. It may ruin the surface of the blocker.

CAUTION: Lightly wipe the exterior of the LCD touch screen. Do not press the LCD touch screen using an object with a hard tip. In addition, keep magnetic objects away from the LCD touch screen. Scratches or failure of the LCD touch screen may result.

CAUTION: Never use a sponge or cloth soaked in water. The water may leak into the inside of the blocker and cause instrument failure.

Is the cover or panel of the blocker clean?

Is the LCD touch screen clean and functional?

Is the lens table clean?

Upload a photo of the cleaned blocker

Sign off on the blocker cleaning

1 Day Intelligent Blocker Check

Check before use

No apparent deformations or dirt interfering with operation

No foreign substances or dirt on the lens table

Does the layout screen appear when the blocker is started?

Lens clamp and blocking arm working properly

Check after use

Is the power turned off?

Blocker is not dirty or damaged

Check all accessories are accounted for and free from damage

Cup Holder Adjustment

Warning: Only trained personnel should perform this adjustment

Is the plunger inside the cup holder loose or worn out?

If yes, proceed with the following steps. If no, end the procedure.

Insert the hexagonal wrench into the hole at the front of the cup holder

Turn the plunger so that the lens cup is fixed securely and it is detached or inserted smoothly

Turn the plunger clockwise to increase the holding power of the lens cup

Is the lens cup now secure?

Sign off on the cup holder adjustment

Parts for Nidec Intelligent Blocker ICE mini

Access the parts list for your equipment in MaintainX.

Fuse

80402-02155

Fuse

80402-02155

Fuse

80402-02155

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX