Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

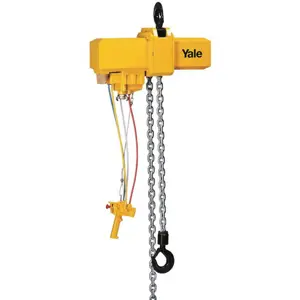

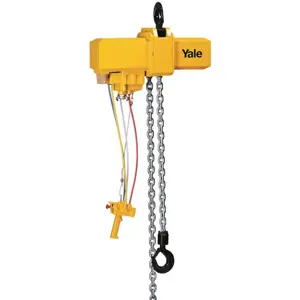

Manual for Hyster-Yale Chain Hoist 0,5t/1

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hyster-Yale Chain Hoist 0,5t/1

Create an account to install this asset package.

Maintenance Plans for Hyster-Yale Chain Hoist Model 0,5t/1

Integrate maintenance plans directly into your work orders in MaintainX.

Load Chain Replacing

Warning: Only authorized personnel should perform this procedure

Visible damage or deformations on the load chain?

If damage or deformations are visible, proceed with the replacement. Otherwise, stop the procedure.

Is the replacement chain of the same dimensions and quality?

Only fit load chains which have been approved by the manufacturer.

Upload a photo of the new chain

Sign off on the load chain replacement

Document the replacement of the load chain

Chain Reeving Inspection

Warning: This inspection requires trained personnel with PPE!

Load chain is not twisted or kinked

If the chain is twisted or kinked, report the issue to the maintenance team and stop the procedure

Did the bottom block roll over?

Chain is reeved correctly with the chain weld facing outwards

Select the type of load chain used

Non-compliance with the specification will render the legal warranty or guarantee void with immediate effect

Sign off on the chain reeving inspection

Load Chain Maintenance

Warning: Ensure the chain is in no-load condition before lubrication.

Is the chain properly lubricated at the link contact points?

Is the chain lubricated over its entire length, including the part in the hoist housing?

Is the chain clean and free of dirt?

Is the change-over area from lifting to lowering movement checked?

Is there any wear on the chain?

ATTENTION: Ensure no lubricant penetrates into the brake enclosure.

Sign off on the load chain maintenance

The Top Hook And Load Hook Inspection

Warning: This inspection requires trained personnel with PPE!

Top hook free of cracks, deformations, damage, wear and corrosion marks

Load hook free of cracks, deformations, damage, wear and corrosion marks

Safety latch moves freely and is fully functioning

Hook free of deformation, damage, surface cracks, wear and signs of corrosion

Does the mouth of the hook opened more than 10%?

Have the nominal dimensions reduced by 5% as a result of wear?

Check the nominal dimensions and wear limits as per table 3

If any limit value is reached, replace the components immediately.

Attachment Point Inspection

Warning: This inspection requires trained personnel with PPE!

Supporting structure has sufficient stability

Unit aligns freely under load

Enter the expected forces that can be safely absorbed by the supporting structure

Enter the details of the supporting structure

Sign off on the attachment point inspection

Parts for Hyster-Yale Chain Hoist 0,5t/1

Access the parts list for your equipment in MaintainX.

Gear Cover, Assy.

00440003

Drive Pinion

00440004

Drive Pinion

00440182

Gear A, Assy.

00440005

Gear B, Assy.

00440006

Gear Cover, Assy.

00440003

Drive Pinion

00440004

Drive Pinion

00440182

Gear A, Assy.

00440005

Gear B, Assy.

00440006

Gear Cover, Assy.

00440003

Drive Pinion

00440004

Drive Pinion

00440182

Gear A, Assy.

00440005

Gear B, Assy.

00440006

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX