Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

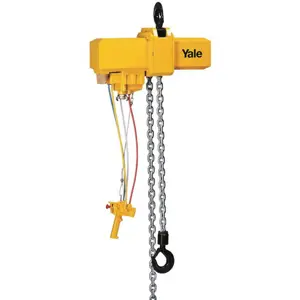

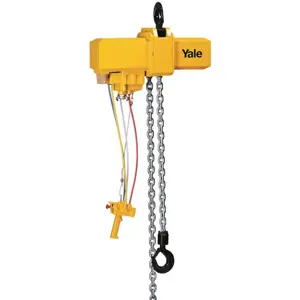

Manual for Hyster-Yale Chain Hoist 1,0t/1

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hyster-Yale Chain Hoist 1,0t/1

Create an account to install this asset package.

Maintenance Plans for Hyster-Yale Chain Hoist Model 1,0t/1

Integrate maintenance plans directly into your work orders in MaintainX.

The Top Hook And Load Hook Inspection

Warning: This inspection requires trained personnel with PPE!

Top hook free of cracks, deformations, damage, wear and corrosion marks

Load hook free of cracks, deformations, damage, wear and corrosion marks

Safety latch moves freely and is fully functioning

No welding on hooks

Measure the mouth of the hook

Measure the nominal dimensions of the hook

Does the hook need to be replaced?

Sign off on the hook inspection

Attachment Point Inspection

Warning: This inspection requires trained personnel with PPE!

Supporting structure has sufficient stability

Expected forces can be safely absorbed

Unit aligns freely under load

Issues found during the inspection

Sign off on the attachment point inspection

Brake Function Check

Warning: This procedure requires trained personnel!

Lift, pull or tension and lower or release a load over a short distance with the unit

Check if the load is held in any position when the hand chain is released

Repeat the above steps at least twice

Is the brake functioning properly?

ATTENTION: If the brake does not function properly, the unit must be immediately taken out of service and the manufacturer must be contacted!

Sign off on the brake function check

Attachment Point Inspection

Warning: This inspection requires trained personnel with PPE!

Supporting structure has sufficient stability

Unit aligns freely under load

Enter the expected forces that can be safely absorbed by the supporting structure

Enter the details of the supporting structure

Sign off on the attachment point inspection

Hand Chain Replacement

Warning: This procedure requires trained personnel with PPE!

Upload a photo of the open load chain link

Is the length of the cut section at least equal to the thickness of the link?

Is the old hand chain opened on the connection link?

Is the open link suspended into the loose end of the hand chain?

Is the new hand chain also suspended in the open link?

Is the new hand chain pulled through the chain guides and over the hand chain wheel?

Is the chain fitted without any twists?

Are the welds facing outwards?

Parts for Hyster-Yale Chain Hoist 1,0t/1

Access the parts list for your equipment in MaintainX.

Gear Cover, Assy.

00440034

Drive Pinion

00440035

Drive Pinion

00440183

Gear A, Assy.

00440036

Gear B, Assy.

00440037

Gear Cover, Assy.

00440034

Drive Pinion

00440035

Drive Pinion

00440183

Gear A, Assy.

00440036

Gear B, Assy.

00440037

Gear Cover, Assy.

00440034

Drive Pinion

00440035

Drive Pinion

00440183

Gear A, Assy.

00440036

Gear B, Assy.

00440037

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX