Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

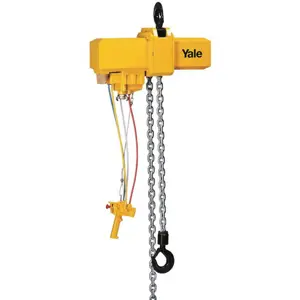

Manual for Hyster-Yale Chain Hoist 2,0t/2

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Hyster-Yale Chain Hoist 2,0t/2

Create an account to install this asset package.

Maintenance Plans for Hyster-Yale Chain Hoist Model 2,0t/2

Integrate maintenance plans directly into your work orders in MaintainX.

The Top Hook And Load Hook Inspection

Warning: This inspection requires trained personnel with PPE!

Top hook free of cracks, deformations, damage, wear and corrosion marks

Load hook free of cracks, deformations, damage, wear and corrosion marks

Safety latch moves freely and is fully functioning

Hook free of deformation, damage, surface cracks, wear and signs of corrosion

Does the mouth of the hook opened more than 10%?

Have the nominal dimensions reduced by 5% as a result of wear?

If any of the above checks fail, replace the hook immediately. Welding on hooks is not permissible.

Sign off on the hook inspection

Hand Chain Adjustment

Warning: For safety reasons, hand chain links may only be used once.

Is the distance of the lower end to the floor between 500 – 1000 mm?

Look for the non-welded link of the hand chain, bend to open and discard it.

Did you shorten or extend the chain to the required length?

ATTENTION: Always remove or add an even number of chain links.

Did you use a new link to close the loose chain ends by bending it?

For extending the hand chain, two new chain links are required.

Did you make sure that hand chains are not twisted while they are fitted?

Sign off on the hand chain adjustment

Load Chain Replacing

Warning: Only authorized personnel should perform this procedure

Visible damage or deformations on the load chain?

If damage or deformations are visible, proceed with the replacement. Otherwise, stop the procedure.

Is the replacement chain of the same dimensions and quality?

Only use replacement chains approved by the manufacturer.

Authorized specialist signature

Upload a photo of the new chain installed

Document the replacement of the load chain

Brake Function Check

Warning: This procedure requires trained personnel!

Lift, pull or tension and lower or release a load over a short distance with the unit

When the hand chain is released, the load must be held in any position

Repeat the above steps at least twice

Did the brake function properly?

ATTENTION: If the brake does not function properly, the unit must be immediately taken out of service and the manufacturer must be contacted!

Sign off on the brake function check

Load Chain Maintenance

Warning: Ensure the chain is in no-load condition before lubrication

Chain lubricated with creep-type lubricant or PTFE spray

Lubricant reached the contact points of the chain links

Chain lubricated over its entire length, including the part in the hoist housing

Chain cleaned with petroleum or similar cleaning agent

Warning: Do not heat the chain

Chain checked for wear during lubrication

Attention: Ensure no lubricant penetrates into the brake enclosure

Sign off on the load chain maintenance

Parts for Hyster-Yale Chain Hoist 2,0t/2

Access the parts list for your equipment in MaintainX.

Gear Cover, Assy.

00440034

Drive Pinion

00440035

Drive Pinion

00440187

Gear A, Assy.

00440036

Gear B, Assy.

00440037

Gear Cover, Assy.

00440034

Drive Pinion

00440035

Drive Pinion

00440187

Gear A, Assy.

00440036

Gear B, Assy.

00440037

Gear Cover, Assy.

00440034

Drive Pinion

00440035

Drive Pinion

00440187

Gear A, Assy.

00440036

Gear B, Assy.

00440037

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX