The Husky 80-Gallon Stationary Air Compressor C801H is a robust and reliable industrial air compressor designed for heavy-duty applications. With its powerful performance and efficient operation, it is ideal for workshops and manufacturing environments requiring consistent air supply.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Husky Husky 80-Gallon Stationary Air Compressor C801H C801H

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Husky Husky 80-Gallon Stationary Air Compressor C801H C801H

Create an account to install this asset package.

Maintenance Plans for Husky Husky 80-Gallon Stationary Air Compressor C801H Model C801H

Integrate maintenance plans directly into your work orders in MaintainX.

Air Filter Replacement

WARNING: Hot surfaces. Risk of burn. Compressor heads are exposed when filter cover is removed. Allow compressor to cool prior to servicing.

CAUTION: Keep the air filter clean at all times. Do not operate the air compressor with the air filter removed. A dirty air filter will not allow the air compressor to operate at full capacity. Keep the air filter clean at all times.

Remove the air filter cover.

Remove the air filter from filter cover.

Place new air filter into filter cover.

Replace air filter cover to pump.

Sign off on the air filter replacement

Air Lines and Fittings Inspection

Turn air compressor off, lock out the power supply, and relieve all air pressure from the air tank.

Apply a soap solution to all air line fittings and connections/piping.

Any leaks found?

Correct any leaks found.

NOTICE: Even minor leaks can cause the air compressor to overwork, resulting in premature breakdown or inadequate performance.

Sign off on the air lines and fittings inspection

Air Compressor Head Bolts Torque Check

Warning: This procedure should be performed by trained personnel only

Enter the hours of operation

Are the air compressor pump head bolts properly torqued?

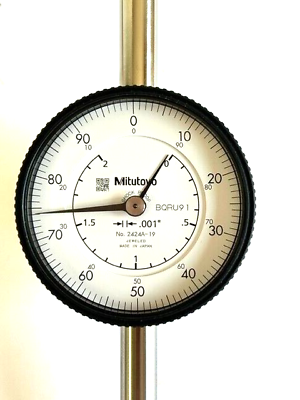

Enter the torque of the head bolts

Sign off on the torque check

1 Yearly Tank Inspection

WARNING: Do not allow brake fluids, gasoline, petroleum based products, etc., to come in contact with plastic parts. Chemicals can weaken or destroy plastic which, may result in serious personal injury.

WARNING: When servicing, use only identical Husky replacement parts. Use of any other parts may create a hazard or cause product damage.

WARNING: Always disconnect the air compressor from the power supply, release all pressure, and allow it to cool before cleaning or making repairs on the air compressor.

Inspect the tank annually for rust, pin holes, or other imperfections that could cause it to become unsafe.

Sign off on the tank inspection

Motor Pulley/Flywheel Alignment

Turn air compressor off, lock out the power supply, and relieve all air pressure from the air tank

Remove belt guard

Place a straightedge against the outside of the flywheel and the motor drive pulley

Measure the distance between the edge of the belt and the straightedge at points A1 and A2 in figure. The difference between measurements should be no more than 1/16” (1.6 mm)

If the difference is greater than 1/16” (1.6 mm) loosen the set screw holding the motor drive pulley to the shaft and adjust the pulley’s position on the shaft until the A1 and A2 measurements are within 1/16” (1.6 mm) of each other

Tighten the motor drive pulley set screw

Visually inspect the motor drive pulley to verify that it is perpendicular to the drive motor shaft. Points B1 and B2 of Figure should appear to be equal. If they are not, loosen the setscrew of the motor drive pulley and equalize B1 and B2, using care not to disturb the belt alignment performed in step 2

Retighten the motor drive pulley setscrew. Torque to 145–165 in lbs (16.4–20.3 Nm)

Reinstall belt guard

Parts for Husky Husky 80-Gallon Stationary Air Compressor C801H C801H

Access the parts list for your equipment in MaintainX.

Filter Canister Assembly

019-0222

Head

042-0117

Element, Filter Replacement

019-0221

Tee Fitting

069-0024

Rod (Outer)

047-0095

Filter Canister Assembly

019-0222

Head

042-0117

Element, Filter Replacement

019-0221

Tee Fitting

069-0024

Rod (Outer)

047-0095

Filter Canister Assembly

019-0222

Head

042-0117

Element, Filter Replacement

019-0221

Tee Fitting

069-0024

Rod (Outer)

047-0095

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX