The Husky 60-Gallon Stationary Air Compressor C601H is a robust and reliable industrial air compressor designed for heavy-duty applications. With its powerful motor and large tank capacity, it delivers consistent air pressure for various pneumatic tools and equipment, making it an essential asset for workshops and job sites.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Husky Husky 60-Gallon Stationary Air Compressor C601H C601H

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Husky Husky 60-Gallon Stationary Air Compressor C601H C601H

Create an account to install this asset package.

Maintenance Plans for Husky Husky 60-Gallon Stationary Air Compressor C601H Model C601H

Integrate maintenance plans directly into your work orders in MaintainX.

Air Filter Replacement

WARNING: Hot surfaces. Risk of burn. Compressor heads are exposed when filter cover is removed. Allow compressor to cool prior to servicing.

CAUTION: Keep the air filter clean at all times. Do not operate the air compressor with the air filter removed. A dirty air filter will not allow the air compressor to operate at full capacity. Keep the air filter clean at all times.

Remove the air filter cover.

Remove the air filter from filter cover.

Place new air filter into filter cover.

Replace air filter cover to pump.

Sign off on the air filter replacement

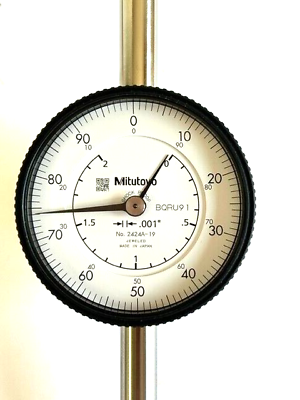

Air Compressor Head Bolts Torque Check

Warning: This procedure should be performed by trained personnel only

Enter the hours of operation

Are the air compressor pump head bolts properly torqued?

Enter the torque of the head bolts in ft.-lbs.

Sign off on the air compressor head bolts torque check

1 Daily Tank Draining

NOTICE: All compressed air systems generate condensate that accumulates in any drain point (e.g., tanks, filter, aftercoolers, dryers). This condensate contains lubricating oil and/or substances which may be regulated and must be disposed of in accordance with local, state, and federal laws and regulations.

NOTICE: If drain valve is plugged, release all air pressure. The valve can then be removed, cleaned, then reinstalled.

Set the Auto/Off switch to “Off”.

Slowly bleed the air from the air tank and air distribution system until tank pressure is approximately 20 psi.

Drain water from air tank by opening drain valve on bottom of tank.

After the water has been drained, close the drain valve. The air compressor can now be stored.

Sign off on the daily tank draining

Safety Valve Check

DANGER: Do not tamper with the safety valve. Items loosened from this device could fly up and hit you. Failure to heed this warning could result in death or serious personal injury.

The safety valve automatically releases air when the receiver pressure exceeds the preset maximum. Check the valve before each day of use by pulling the ring by hand.

WARNING: If air leaks after releasing the safety valve ring or if the valve is stuck, do not use the air compressor until the safety valve has been replaced. Using the air compressor in this condition could result in serious personal injury.

Set the Auto/Off switch to “On”. and wait for the tank to fill. The compressor automatically shuts off when the pressure reaches the preset maximum.

Set the Auto/Off switch to “Off”.

Pull the ring on the safety valve for 20 seconds to release the air.

Release the ring. Air stops escaping at about 20 psi. If air continues to escape after releasing the safety valve ring, discontinue use and seek service before using the air compressor again.

Sign off on the safety valve check

Motor Pulley/Flywheel Alignment

Turn air compressor off, lock out the power supply, and relieve all air pressure from the air tank

Remove belt guard

Place a straightedge against the outside of the flywheel and the motor drive pulley

Measure the distance between the edge of the belt and the straightedge at points A1 and A2 in figure. The difference between measurements should be no more than 1/16” (1.6 mm)

If the difference is greater than 1/16” (1.6 mm) loosen the set screw holding the motor drive pulley to the shaft and adjust the pulley’s position on the shaft until the A1 and A2 measurements are within 1/16” (1.6 mm) of each other

Tighten the motor drive pulley set screw

Visually inspect the motor drive pulley to verify that it is perpendicular to the drive motor shaft. Points B1 and B2 of Figure should appear to be equal. If they are not, loosen the setscrew of the motor drive pulley and equalize B1 and B2, using care not to disturb the belt alignment performed in step 2

Retighten the motor drive pulley setscrew. Torque to 145–165 in lbs (16.4–20.3 Nm)

Reinstall belt guard

Parts for Husky Husky 60-Gallon Stationary Air Compressor C601H C601H

Access the parts list for your equipment in MaintainX.

Filter

019-0220

Gasket

046-0282

Tube Compression Nut Assembly

E105998

Screen

118-0032

Crankcase

049-0048

Filter

019-0220

Gasket

046-0282

Tube Compression Nut Assembly

E105998

Screen

118-0032

Crankcase

049-0048

Filter

019-0220

Gasket

046-0282

Tube Compression Nut Assembly

E105998

Screen

118-0032

Crankcase

049-0048

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX