Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

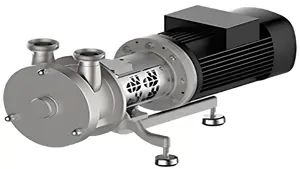

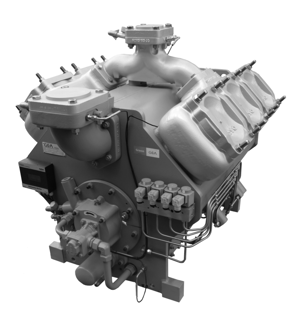

Manual for GEA Compressor Bock HGX44e/770 (S/ML) 22 LG

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

GEA Compressor Bock HGX44e/770 (S/ML) 22 LG

Create an account to install this asset package.

Maintenance Plans for GEA Compressor Model Bock HGX44e/770 (S/ML) 22 LG

Integrate maintenance plans directly into your work orders in MaintainX.

Initial 100 Hours Compressor Oil Change

WARNING: Before starting any work on the compressor: Switch off the compressor and secure it to prevent a restart. Relieve compressor of system pressure. Prevent air from infiltrating the system!

Compressor switched off and secured?

Compressor relieved of system pressure?

Prevention of air infiltration ensured?

After maintenance has been performed: Connect safety switch. Evacuate compressor. Release switch lock.

Safety switch connected?

Compressor evacuated?

Switch lock released?

Change compressor oil for field installations or when operating near the application limit: for the first time after 100 to 200 operating hours.

1 Yearly Compressor Maintenance

WARNING: Before starting any work on the compressor: Switch off the compressor and secure it to prevent a restart. Relieve compressor of system pressure. Prevent air from infiltrating the system!

Oil level check

Leak tightness check

Running noises check

Pressure check

Temperature check

Function of auxiliary devices check

After maintenance has been performed: Connect safety switch. Evacuate compressor. Release switch lock.

Additional information when using flammable refrigerants WARNING: During maintenance and repair, it must be noted that hydrocarbon and synthetic HFO refrigerants residues may dissolve in the oil. Therefore, electrical tests must not be conducted while oil remains in the compressor.

10000 Hourly / 3 Yearly Compressor Oil Change

- Change compressor oil every 3 years or 10,000 - 12,000 operating hours.

Dispose of used oil according to the regulations; observe national regulations.

WARNING; Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Prevent air from infiltrating the system!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX