Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

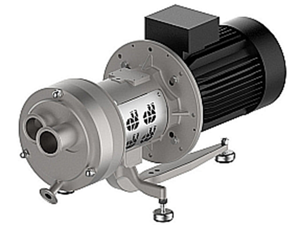

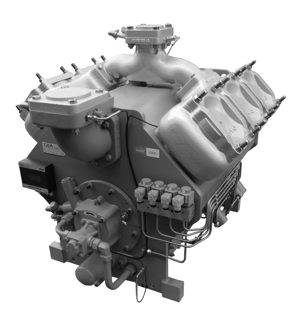

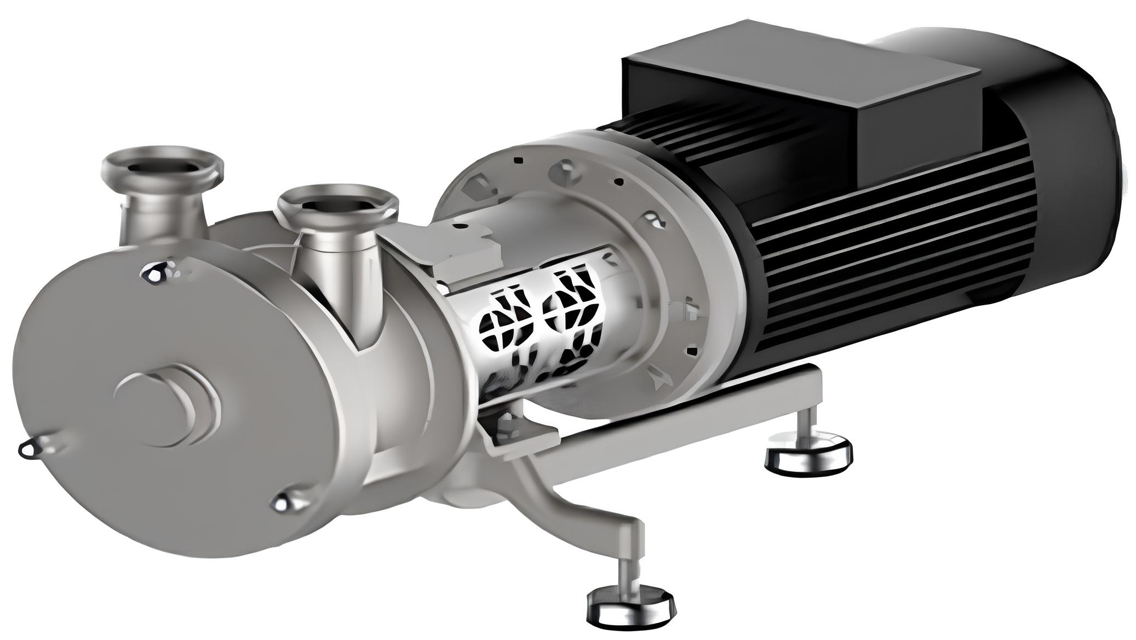

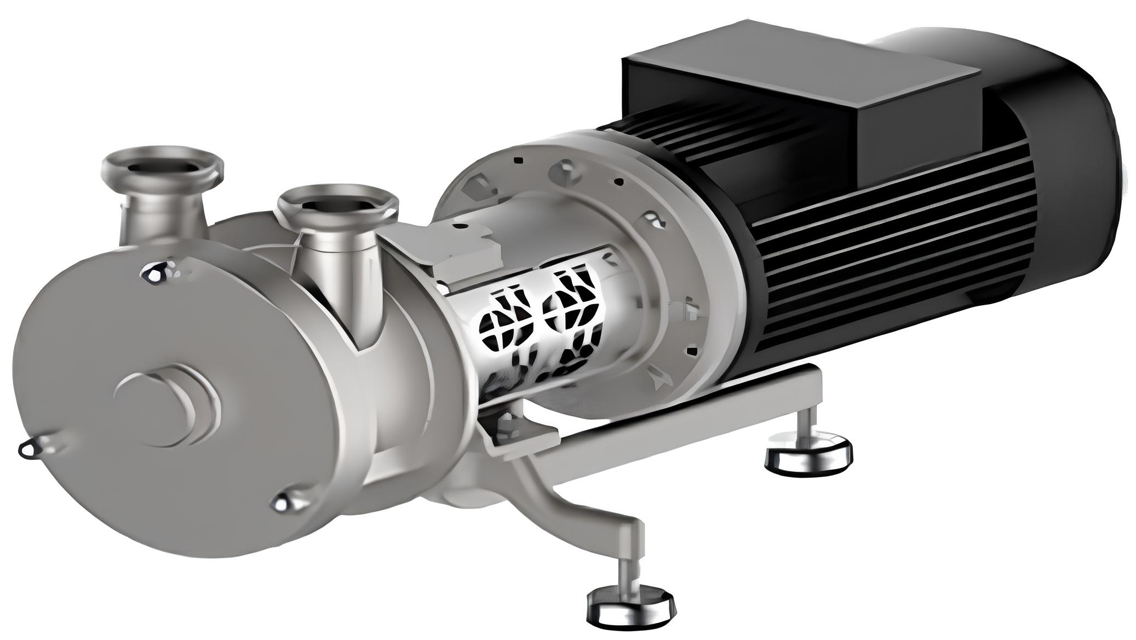

Manual for GEA Hygienic Pump Hilge SIPLA HT ADAPTA 18.1

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

GEA Hygienic Pump Hilge SIPLA HT ADAPTA 18.1

Create an account to install this asset package.

Maintenance Plans for GEA Hygienic Pump Model Hilge SIPLA HT ADAPTA 18.1

Integrate maintenance plans directly into your work orders in MaintainX.

Hygienic Pump Inspection

Commissioning

Functional testing of the mechanical seal

Inspect the pump and check whether liquid exits at the mechanical seal

An intact mechanical seal operates virtually without any leakage

If pumped fluid or flushing fluid exits

Switch off the pump

Replace the mechanical seal

Follow the installation instructions Section 10.2, Page 44

O-rings Replacement

Notice: Hygiene risk, food safety. Worn out and not fully functional components may lead to the contamination of the pump.

Pay close attention to the condition of the O-rings during regular inspections.

The O-rings must be replaced if any one of these characteristics are visible

O-ring replaced successfully?

Sign off on the O-rings replacement

5000 Hourly Bearing Replacement

Warning: This procedure requires trained personnel with PPE!

Enter the machine's operating hours

If operating hours are above 5000, proceed with the bearing replacement

Select the type of external influence

Bearing replaced successfully?

Sign off on the bearing replacement

2000 Hourly Pump Inspection

Warning: This inspection requires trained personnel with PPE!

Visual inspection of the pump

Leak tightness check

Functionality check of the pump

After 2000 hours of operation, check the following:

Mechanical seal check

O-rings check

During disassembly of the pump, check the following:

All seals check

Hygienic Pump Check

All connections are firmly secured

All safety devices are installed

Electrical connections are correct

Pipe system on the installation side is clean

Stop valves in the system are open

Pump along with the system is filled

Pump along with the system is vented

For double mechanical seal / quench version, flushing fluid is connected without pressure (max. 0.2bar)

Suction-side stop valve is fully open

Parts for GEA Hygienic Pump Hilge SIPLA HT ADAPTA 18.1

Access the parts list for your equipment in MaintainX.

Pump Housing

0101

Suction Nozzle

0153

Pressure Nozzle

0156

Dome Stand

0180

Bearing Support

0330

Pump Housing

0101

Suction Nozzle

0153

Pressure Nozzle

0156

Dome Stand

0180

Bearing Support

0330

Pump Housing

0101

Suction Nozzle

0153

Pressure Nozzle

0156

Dome Stand

0180

Bearing Support

0330

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX